From leak-free pumps in chemical processing to clean delivery in food production, magnetic couplings play a vital role. But do you understand the basic common sense of coupling magnetic fields involved? Follow me from coupling magnetic fields to decoupling mechanisms to protect the stressed machinery. And introduce technical common sense such as magnetic exchange coupling, coupling coefficient, and coupling constant to help you better understand the magnetic coupling design process.

What is coupling magnetic field?

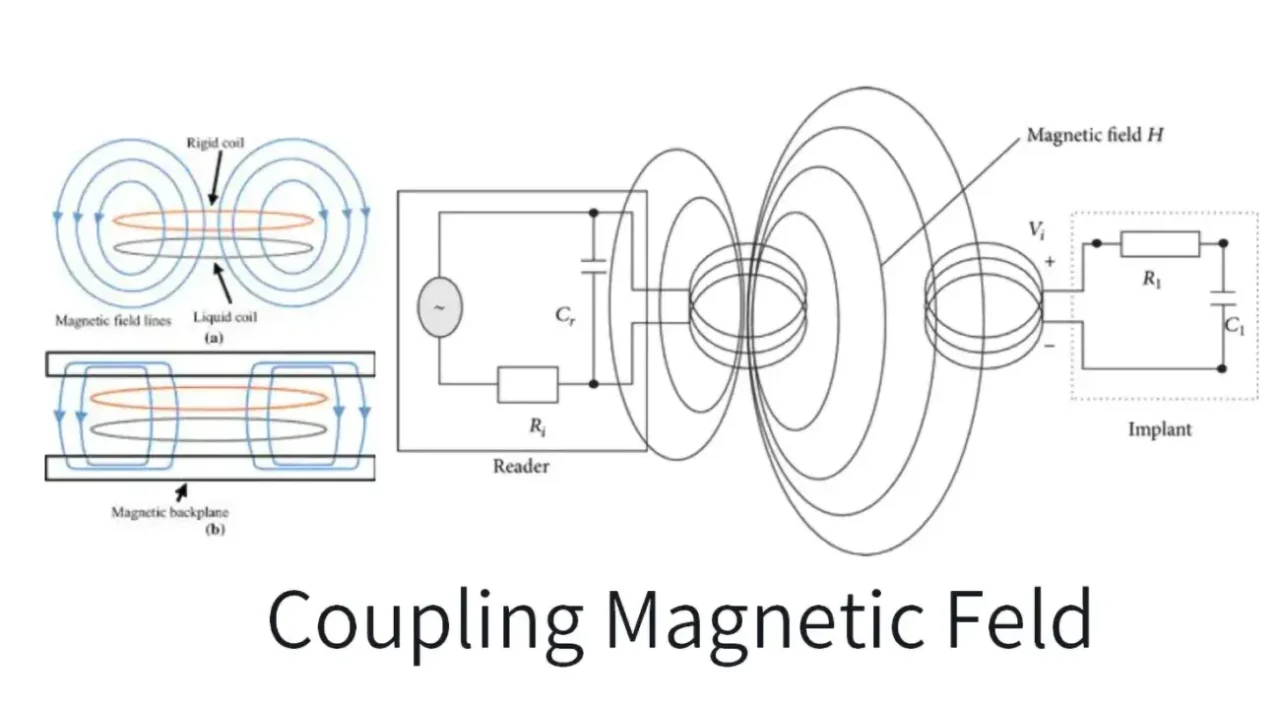

Coupled magnetic fields are the basic principle of how magnetic couplings can transmit torque without any physical contact. Magnetic coupling occurs when energy is transferred from one active shaft magnet to another driven shaft magnet through a magnetic field, causing them to rotate synchronously. This physical phenomenon is able to transmit motion across physical barriers without the need for any gears or mechanical linkages. No physical connections to worry about wearing out or breaking. Everything is transmitted through the invisible force of the magnetic field, which eliminates the risk of leaks or contamination.

What is high magnetic coupling?

High magnetic coupling takes magnetic coupling to the next level: the magnetic field is stronger, the alignment is more precise, and the energy loss is minimized. It can withstand more torque without slipping, allowing the magnetic field torque to be transmitted better, faster, and longer.

For example, if you run a high-performance pump or agitator in a chemical plant, high magnetic coupling ensures smooth operation even under extreme pressures and speeds. It’s like having a high-end sports car that handles perfectly even at top speeds.

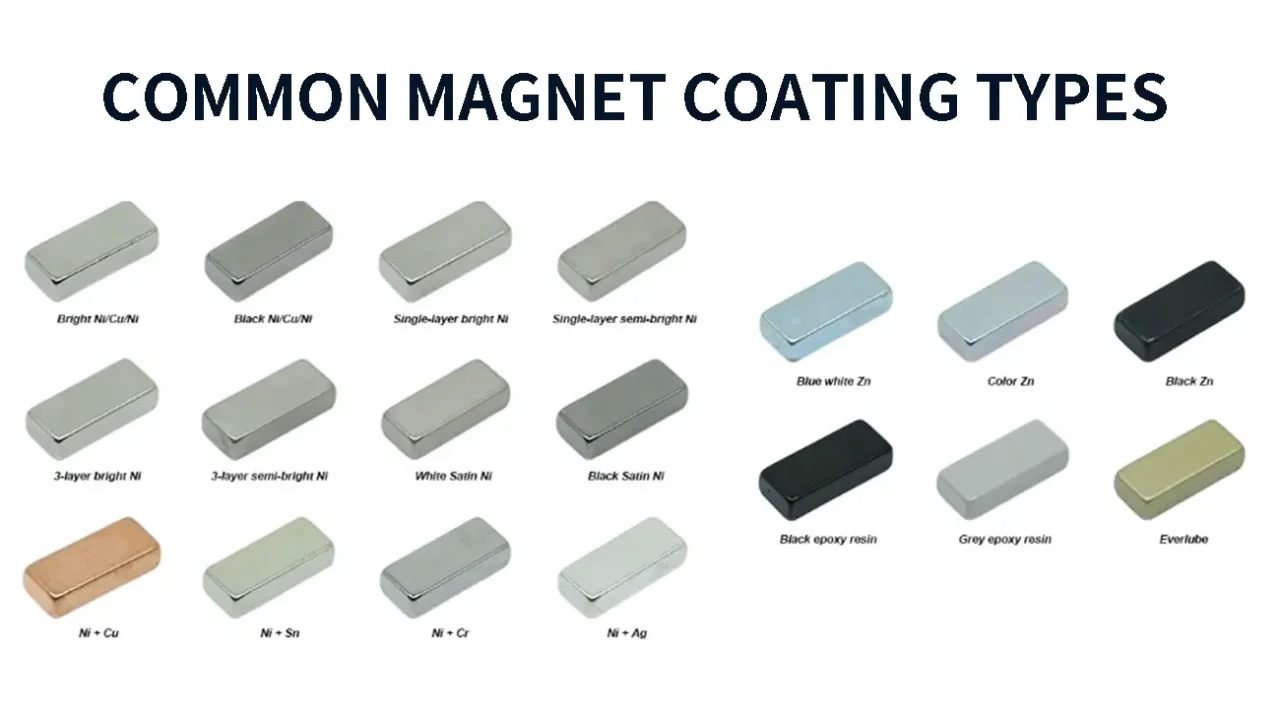

But it’s not just about sticking magnets together, it’s about the strength and alignment of the magnetic field. The transmitted torque depends on the strength of the magnets, the distance between the magnets and the degree of alignment of the magnetic field (knowledge about how to achieve the maximum torque of magnetic coupling can be found in our corresponding blog). In fact, when we deal with coupling magnetic fields, we must consider the concept of magnetic saturation. If the magnets are loaded beyond their ability to handle torque, they will not be able to transmit the required motion, resulting in the eventual slip of the magnetic coupling system. This is why we always emphasize magnetic saturation and magnetic field strength during the production process.

What is decoupling?

From the above knowledge, we already know that the coupling magnetic field effect can be generated without physical contact in the magnetic coupling. But be aware that magnetic drives are sensitive to extreme operating conditions of excessive torque. These magnets can lose alignment under excessive stress, and decoupling occurs, with the magnets on the two shafts no longer transmitting torque effectively. In the world of magnetic couplings, decoupling is all about protection and control, designed with built-in safety measures. When slip occurs, the system disconnects or decouples, protecting the machine from overloads that could cause expensive wear or damage.

Imagine a high-speed pump handling a hazardous fluid. If resistance unexpectedly spikes (perhaps due to a blockage), the magnetic coupling automatically decouples after reaching its torque limit. This protects the motor from permanent demagnetization of the magnets or damage to the machine, and gives the operator a chance to resolve potential issues before they escalate.

What is magnetic exchange coupling?

Magnetic exchange coupling refers to a quantum mechanical interaction between two or more neighboring electrons. This is a key concept if you want to understand how magnetic coupling works from a deeper, more technical perspective. Each atom has its own magnetic moment, which acts like a little compass needle. When these moments interact, they can align in the same direction or in opposite directions depending on how they relate to each other. This interaction, similar to an “Exchange interaction” determines the overall magnetic behavior of the material.

Magnetic exchange coupling can be divided into 3 technical types: direct exchange coupling, exchange coupling across a material interface, and RKKY coupling.

- Direct exchange coupling between neighboring atoms

When two atoms sit next to each other, their magnetic moments influence each other because their electron clouds overlap slightly. This overlap creates a force that causes their magnetic moments to either point in the same direction (ferromagnetic) or in opposite directions (antiferromagnetic). This is the most basic form of exchange coupling, and you can see it in many common magnetic materials. - Exchange coupling across material interfaces

This coupling comes into play whenever two dissimilar materials are in contact with each other – such as a ferromagnet next to an antiferromagnet in an exchange-biased system. One likes to go with the flow (ferromagnet), while the other is more organized and stubborn (antiferromagnet). When they meet at an interface, their interaction creates a unique magnetic property. This exchange coupling is often used to create stable, directional magnetic fields and is widely used in magnetic storage technology. - RKKY coupling

Rudman-Kittel-Kasuya-Yoshida (RKKY) coupling is a long-range interlayer coupling in which atoms do not directly affect their neighbors, but rather through conduction electrons in the material. It gets a little more complicated because it occurs over a longer distance. Imagine two people trying to coordinate their movements in a room, but instead of talking directly, they communicate through other people scattered around the room. This effect causes magnetic moments in different layers of the material to align or oppose each other.

These invisible conversations between atoms fundamentally shape the material’s behavior. Understanding and manipulating these atomic interactions could open up possibilities for new technologies, better magnets, and more efficient energy transfer systems.

What is coefficient of magnetic coupling?

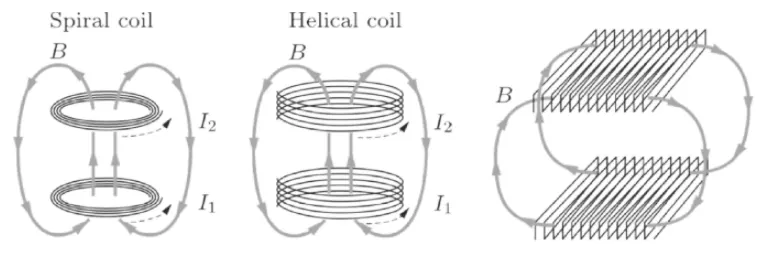

The magnetic coupling coefficient, also known as the coupling coefficient, is an indicator that defines the magnetic flux generated by the current in one coil that connects to the other coil (the degree of magnetic coupling). It is usually between 0 and 1. When the coefficient is close to 1, the coupling is strong – most of the magnetic energy generated by one magnet is effectively received by the other magnet. A value of 1 for the coupling coefficient is called perfect coupling. When the coefficient is close to 0, there is not much energy transferred between them, or even no coupling benefit. So, the magnetic coupling coefficient affects how well the torque or force is transferred from one magnetic part to another in the coupler.

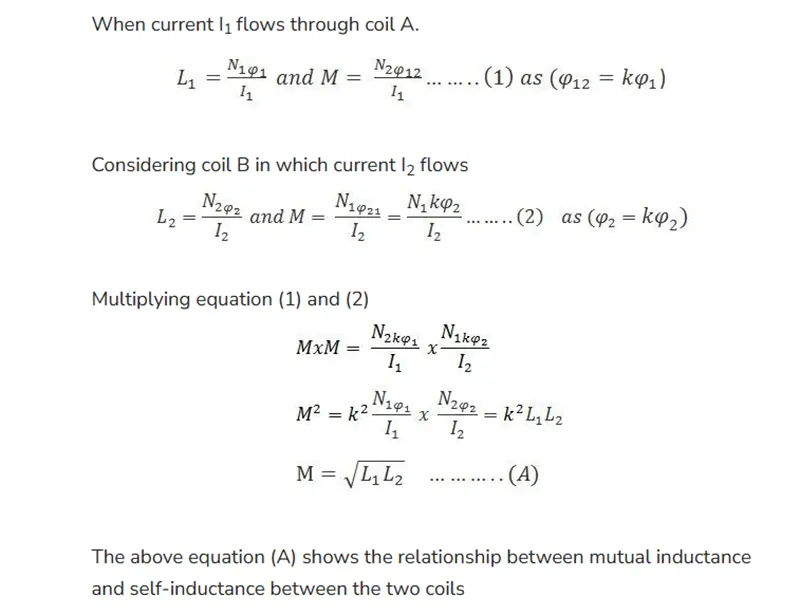

The coupling coefficient is usually represented by the symbol (k) and is calculated as “k = M / (sqrt(L1 * L2))”, where “M” is the mutual inductance between the coils, “L1” is the self-induction of the first coil, and “L2” is the self-induction of the second coil.Click to see more detailed steps for calculating the coupling coefficient.

Knowing this factor and applying it during the manufacturing process of magnetic couplings helps us optimize torque transmission and reduce power losses. If the coefficient is not high enough, the coupling may experience slippage. I think the coupling coefficient is an important indicator of the reliability of magnetic couplings: a high coefficient means reliable torque transmission, minimal energy loss, and generally less wear and tear on the device.

What is the magnetic coupling constant?

The concept of magnetic coupling constant was originally derived from the interaction of nuclear magnetic dipoles, indicating the intensity of the influence of the magnetic field of one nucleus on the magnetic field of another nearby nucleus. It is represented by the symbol “J” and is measured in Hertz (Hz).

The coupling constant used in the magnetic coupler industry usually refers to a value that quantifies the strength of the magnetic interaction between two magnetic moments. This provides data guidance for engineers to set the magnetic component strength and spacing fine-tuning process. If the magnetic coupling constant is higher, a stronger connection can be achieved over a larger area, which is critical in high-performance applications.

By clarifying key concepts such as coupled magnetic fields, decoupling mechanisms, and exchange coupling and coupling coefficients, we have gained insight into why magnetic coupler components are essential in complex machinery. For businesses seeking durable, custom magnetic couplers, Osencmag offers professional and reliable manufacturing solutions. Contact us for bulk orders or custom designs to meet your unique project requirements.

How does decoupling protect machinery in magnetic couplings?

Decoupling is like an automatic protection device. When the torque or resistance exceeds a set threshold, the magnets in the coupling “slip”, disconnecting and protecting the motor from damage.

What role does the coupling magnetic field play in torque transfer?

The coupling magnetic field is the heart of torque transfer in magnetic couplings. This magnetic field is generated between magnets on two independent shafts, allowing power to be transferred without direct contact. The strength and arrangement of this magnetic field determines the efficiency of torque transfer.

Why is the magnetic coupling constant important?

The magnetic coupling constant determines the strength of the magnetic connection. A higher constant means a stronger magnetic connection, allowing for smooth transmission of greater torque.

How does temperature affect magnetic coupling performance?

High temperatures accelerate the demagnetization of magnets and weaken the magnetic field, affecting coupling strength and efficiency. Most magnetic couplings are designed to operate within a specific temperature range to maintain consistent performance. Of course, there are many other factors that affect the power of magnetic couplings, and you can learn more about them in our corresponding blog.