Custom precast shuttering magnet manufacturer

Shuttering magnets are also known as precast concrete magnets. They provide a cost-effective solution for securing formwork to cast concrete elements with precision and reliability. Osencmag is proud to provide high-quality, custom shuttering magnets that meet the unique needs of the precast concrete industry.

OEM Precast Shuttering Magnet Supplier

Types of Shuttering Magnets

Shuttering Magnets of various types (side suction, flat suction, right angle shuttering magnets, Magfly precast shuttering magnets) for specific applications are available to ensure optimal performance and reliability for your precast concrete projects.

Surface treatment

Shuttering magnets can be customized with various surface treatments, such as protective coatings such as galvanizing, nickel plating, phosphating or epoxy to enhance durability and corrosion resistance.

Rally customization

Customize the tension of the precast shuttering magnet according to specific requirements to ensure the best performance of your precast concrete project and ensure the safety and stability of the precast shuttering.

Permanent magnet material temperature rating

The neodymium magnet grade specifications in the shuttering magnet assembly can be selected according to the actual application environment and requirements to improve the temperature resistance applicability of the precast shuttering magnet.

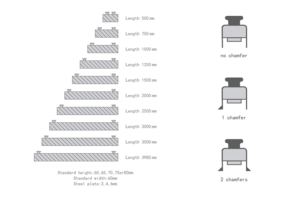

Size customization

Our shuttering magnets can be customized according to customer-specific template size requirements to perfectly match your project needs.

Functional integration

We can integrate threaded holes or stepped patterns into the precast Shuttering magnet box for easy connection and adjustment, thus enhancing the flexibility and usability of template settings.

From China's Leading Precast Shuttering Magnets Supplier

Osencmag is a powerful supplier of magnetic technology for precast concrete formwork in China. For over two decades, we have provided fully customizable shuttering magnet manufacturing to over 30 companies around the world. All are made from the finest materials and the most precise manufacturing techniques to last. We offer a full range of precast shuttering magnet forming solutions in a variety of sizes and strengths.

High-Quality Shuttering Magnets from a Leading Factory

-

Shuttering Magnets

L-shaped Corner Precast Concrete Steel Mold Shuttering Magnets

-

Shuttering Magnets

Triangular precast concrete magnet magnetic chamfer strip

-

Shuttering Magnets

Precast Shuttering Magnets Box with Support Rod

-

Shuttering Magnets

Embedded channel U-shaped steel concrete Shuttering Magnets

-

Shuttering Magnets

Aluminum Magfly precast Shuttering Magnets

-

Shuttering Magnets

Permanent magnet precast shuttering magnetic boxes

-

Shuttering Magnets

High performance 3000kg carbon steel precast concrete shuttering magnet

-

Shuttering Magnets

Customizable extra long strip precast concrete Shuttering Magnets

Conventional shutter magnet specification sheet

| Model | Dimension (mm) | Cover material | Net weight (kg) | Attractive forece (kg) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | W | H | L1 | L2 | L3 | H1 | H2 | H3 | S | ||||

| OSENC600 | 210 | 60 | 40 | 92.5 | 71.5 | 40 | 74 | 65 | – | M12 | S304 | 1.9 | 600 |

| OSENC800 | 210 | 62 | 54 | 85 | 85 | – | 88 | 79 | – | M12 | Q235 | 2.8 | 800 |

| OSENC900 | 210 | 62 | 54 | 85 | 85 | – | 88 | 79 | – | M12 | Q235 | 3.0 | 900 |

| OSENC1000A | 200 | 98 | 40 | 99.5 | 67.5 | 50 | 75 | 65 | 10 | M12 | S304 | 2.8 | 1000 |

| OSENC1000B | 240 | 68 | 54 | 90 | 90 | – | 88 | 79 | – | M12 | Q235 | 3.2 | 1000 |

| OSENC1800A | 260 | 120 | 60 | 112 | 112 | – | 94 | 85 | – | M16 | S304 | 5.7 | 1800 |

| OSENC1800B | 260 | 120 | 60 | 112 | 112 | – | 94 | 85 | – | M16 | Q235 | 6.3 | 1800 |

| OSENC2100A | 320 | 120 | 60 | 136 | 136 | – | 94 | 85 | – | M16 | S304 | 7.3 | 2100 |

| OSENC2100B | 320 | 120 | 60 | 136 | 136 | – | 94 | 85 | – | M16 | Q235 | 7.4 | 2100 |

| OSENC2400A | 320 | 120 | 60 | 136 | 136 | – | 94 | 85 | – | M16 | S304 | 7.5 | 2400 |

| OSENC2400B | 320 | 120 | 60 | 136 | 136 | – | 94 | 85 | – | M16 | Q235 | 7.6 | 2400 |

| OSENC3000 | 320 | 160 | 60 | 136 | 136 | – | 94 | 85 | – | M16 | Q235 | 10.6 | 3000 |

Why Choose Us as Your Shuttering Magnet Supplier

By choosing Osencmag as your shuttering magnet manufacturer, you benefit from our commitment to quality, innovation, and customer satisfaction.

Strong Magnetic Force

Our magnets are made of high-quality neodymium material, which provides excellent holding force. Prevent any unwanted movement or misalignment of precast Shuttering magnets. The standard 2100kg tensile force Shuttering magnet can reach more than 2200kg.

Precision Manufacturing

High-precision manufacturing allows the shuttering magnet assembly to have a smaller gap to prevent foreign matter (concrete) from entering the interior of the shuttering magnet, improving its stability. When concrete penetrates, the magnet becomes unstable and unsafe.

Convenient Operation

Ease of use is a key aspect of our shuttering magnets. The user-friendly on/off switch mechanism can be easily activated and deactivated, simplifying the formwork setting and removal process. Reduce labor costs.

Protective Coating

Supports protective coating treatments such as zinc plating, nickel plating, phosphating and nano-aluminum on the surface of the shuttering magnets to prevent rust and improve surface corrosion resistance. Extend its service life and maintain its effectiveness in various environments.

High-quality springs

Shuttering magnets are equipped with high-quality alloy steel springs to ensure consistent and reliable performance even under heavy loads and frequent use.

Compatibility

We support customized production of shuttering magnets according to different application templates to suit a variety of applications. Whether you produce standard panels or customize unique precast shuttering magnets, support seamless integration.

Packaging and transportation

In addition to basic anti-collision and waterproof packaging, we also use magnetic isolation packaging to perfectly cope with many cumbersome rules in magnetic transportation. And choose the logistics company based on the most convenient transportation method for customers.

Quality control

From the tensile performance of neodymium magnets to the raw material selection of steel shells, we provide higher quality shuttering magnets in all aspects. A series of strict quality control management systems are implemented in manufacturing, production, strength testing, etc.

What is Shuttering Magnet?

Shuttering magnets, also known as concrete magnets, magnetic formwork systems or permanent fixture magnets, allow you to quickly create temporary setups. It is one of the most important accessories for precast concrete magnets, mainly used to fix side rails and stops when pouring concrete. It provides an efficient, reliable and reusable solution for fixing the formwork during the casting of concrete components. Unlike traditional methods that rely on mechanical fasteners or tapes, formwork magnets use strong magnetic forces to fix the formwork in place, ensuring precision and stability. They can also fix steel plates, beams, doors and molds in place. This flexible magnetic system saves you a lot of time, money and manpower, making it a popular and cost-effective solution for building components.

Working principle of precast Shuttering Magnet.

The working principle of precast shuttering magnets is based on the principle of magnetic force, which mainly forms a strong holding force around an array of powerful neodymium magnets installed in a solid steel housing. Since the concrete module production is carried out on the surface of the steel casting bed, the connection between the shuttering box and the steel casting bed can be achieved by neodymium magnets. The sintered neodymium iron boron magnets form a special magnetic circuit with the steel plate machine bed, fixing the shuttering to the steel casting bed.

When using precast concrete magnets, the air gap at the bottom of the shuttering magnet can be controlled to achieve a switching effect. The shuttering magnets usually have an on/off switch mechanism, which can be easily positioned and adjusted. When the switch is in the “off” position, the magnetic field is contained within the housing, allowing the shuttering to be easily placed and repositioned. Once the desired position is achieved, the magnetic field is activated by flipping the switch to the “on” position. This strong connection ensures that the shuttering remains stable during the concrete pouring and curing process. After the concrete has solidified, the shuttering can be easily removed by switching the magnet to the “off” position, thereby disconnecting the magnetic field (there will be a gap between the magnet and the platform. The magnetic circuit is not saturated and the adhesion suction is reduced). Always pay attention: there must be good contact with the surface, because even small air gaps reduce the holding force.

This type of magnetic attraction simplifies the process of removing the formwork and prepares the formwork magnets for reuse in the next production cycle.

The formwork magnet box and the corresponding bottom steel casting bed require highly secure stability so that the loads generated by the pressure of the newly flowing concrete and the forces generated during the compaction of the built-in parts can be transmitted horizontally and vertically. With the help of modern formwork magnets and corresponding additional products, it is now possible to transmit very large forces in precast concrete formwork magnets. As a leading factory in China, we produce high-quality formwork magnets that can withstand even the most severe conditions. Our products are designed to help you save time and money while improving the quality of your concrete formwork.

Application of Shuttering Magnet.

Formwork magnets can be used to fix wooden boards, steel plates, beams, fences and molds on steel platforms, are easy to move & fix on steel platforms and are available in various shapes to match building designs. Formwork magnets are increasingly used in the industrial production of precast concrete components. Since most precast concrete parts such as various types of walls, columns, floor slabs and even roofs from family homes to large buildings are produced in or on steel formworks, the use of permanent magnets to fix formwork magnet boxes has become a common practice in the large-scale construction industry. Its ultra-high durability, flexibility and economy have become the basis for many construction companies as a new working method. Here are some common uses:

- Precast Concrete Panels:Shuttering magnets are essential for producing precast concrete panels, including walls, floors, and facades. They ensure that the formwork is securely held in place, allowing for precise and uniform casting of large concrete elements.

- Beam and Column Production:In the production of beams and columns, shuttering magnets provide stability to the formwork, maintaining the desired shape and dimensions.

- Custom Concrete Elements:Shuttering magnets enable the creation of custom-designed concrete elements, such as architectural features and decorative panels. The flexibility of magnetic formwork systems allows for intricate designs and complex shapes to be cast with high precision.

Shuttering magnets represent a significant advancement in the precast concrete industry, offering a powerful, efficient, and reusable solution for formwork fixation. Whether producing standard panels, complex custom elements or key cement structure components, shuttering magnets can help construction companies improve the quality and efficiency of the concrete production process.

Prefabricated concrete modules using shuttering magnets.

Why do we need Precast Shuttering Magnets?

Precast formwork magnets offer a host of game-changing features that help industries, especially architectural concrete, become more efficient and convenient. In the ever-evolving world of precast concrete production, the need for efficiency, precision and sustainability is ever-advancing. Osencmag understands these needs and has developed a complete precast formwork magnet supply chain to meet and exceed industry expectations.

- The accuracy of formwork placement directly affects the quality of the finished concrete. Because the neodymium magnets in our Shuttering Magnet have super strong magnetic attraction, they have extremely high adhesion to ensure that precast concrete shuttering is firmly fixed in place, maintaining the required shape and size of the concrete component. This precision is essential to produce high-quality precast components that meet strict industry standards.

- No drilling or welding is required, and there is no need to bolt the formwork table. Shuttering Magnet provides a non-destructive fixing method, the formwork or steel surface will remain intact, which means your formwork and steel will last longer.

The demands of modern construction projects often require custom-designed concrete elements. Our precast concrete formwork magnets are versatile and can create complex shapes and intricate designs. Whether it is an architectural feature or a structural component (including walls, columns, slabs and beams), we can provide the shuttering magnets needed to meet a variety of design specifications.

The reuse of formwork is a key factor in reducing production costs. Our formwork magnets are designed to be durable and reusable, ensuring that they remain in circulation during the production cycle. By minimizing the need for new formwork materials, it helps to achieve significant cost savings and sustainability in precast concrete manufacturing.

- Time is a key factor in any manufacturing process, and the production of precast concrete elements is no exception. Traditional formwork methods often require long installation and removal times. Our precast Shuttering Magnet can significantly simplify these processes and reduce precast Shuttering installation and removal time. Easy to use Installation is very simple and 60% faster than traditional methods. Effectively reduce labor costs.

- Extremely versatile, it can be used with either wood or steel formwork.

- With a strong adsorption range, the Precast Shuttering Magnet can withstand weights from 450Kg to 3100Kg.

- The Shuttering Magnet box can integrate threaded holes to adapt to different formworks.

In short, precast concrete formwork magnets are the key to quickly and easily forming concrete. Compared with traditional methods, they have many irreplaceable advantages. With years of industry experience and an excellent track record, we are the precast Shuttering Magnet supplier you can trust. Contact us today to learn more about custom Shuttering Magnets and how we can help you improve your construction projects.

Structural analysis of Shuttering Magnet.

Shuttering magnets, crucial in the realm of precast concrete construction, are meticulously engineered devices composed of several key components. Each part plays a vital role in ensuring the magnet’s performance, reliability, and longevity. Follow me to disassemble the structure of the shuttering magnet and analyze the function and role of each component.

- Steel Housing: The steel housing is the outer shell of the precast shuttering magnet, providing strong protection and structural integrity. The high-grade steel used in the housing ensures that the magnet will last a long time even in harsh construction environments due to its durability and corrosion resistance. Our factory performs strict quality control processes including tensile strength and impact resistance testing to ensure that the steel housing meets the highest standards of durability and reliability.

- External Attachment Screws: The external attachment screws are used to fix the formwork magnet to the external steel housing. These screws must withstand tremendous shear and tensile forces during the concrete casting process. These screws are usually made of hardened steel and are precision machined to ensure a perfect fit and a secure connection. Quality assurance of the screws includes checking for uniform thread pattern, tensile strength and wear resistance.

- Magnetic Core: The heart of the shuttering magnet is the array core, which consists of neodymium magnets bonded to a steel block. The excellent magnetic strength of the neodymium magnet provides a strong holding force to help produce precast concrete. We use high-strength adhesives and strict alignment procedures during the bonding process to ensure that the magnetic core operates at peak efficiency. Each batch of finished products will be tested for magnetic field strength, bond integrity, and thermal stability before shipment.

- Control switch: The control switch is a key component that allows the user to activate and deactivate the magnetic field. The type of switch provides different forms such as pull-lever, press-on, etc. depending on the shuttering magnet type. We perform cycle testing to ensure that the switch can withstand thousands of operations without failure, as well as ergonomic evaluations to ensure user-friendly operation.

- Spring: The spring in the shutter magnet plays a vital role in the activation and deactivation process. When the control switch is switched, the spring mechanism helps to engage or disengage the magnetic field. We source high-quality spring steel to provide excellent fatigue resistance and elasticity.

- Studs for fixing the shutter magnet box: The studs inside the shutter magnet box are key components that connect the control switch to the magnetic core and the steel housing. They play a key role in maintaining the structural integrity of the precast concrete formwork magnets. They ensure that all internal components remain precisely aligned and firmly fixed, thereby improving the overall reliability and durability of the shutter magnet. The quality control of these studs includes strict dimensional accuracy inspections, tensile strength tests, and mechanical fatigue resistance evaluations to ensure that they provide consistent performance throughout the life of the magnet.

I believe that through such a disassembly, you have a certain understanding of the detailed structure and function of the components behind precast concrete magnets. The structural components of any batch of our formwork magnets are carefully designed and manufactured to ensure optimal performance in precast concrete applications. From the durable steel housing and precise external connection screws to the powerful neodymium core, reliable control switch, elastic spring and sturdy fixing studs, each component is carefully crafted and strictly quality tested.

FAQs about precast shuttering magnet

What are the benefits of using shuttering magnets in precast concrete production?

Benefits include reduced setup time, precise positioning, reusability, elimination of welds and bolted connections, enhanced safety, and improved working conditions. These precast shuttering magnets also help reduce waste and increase overall production efficiency.

Can shuttering magnets be customized for specific projects?

Yes, shuttering magnets can be customized for specific project requirements. Customization options include different sizes, shapes, and magnetic strengths to accommodate a variety of precast concrete elements and formwork configurations.

What factors should be considered when selecting a precast shuttering magnet?

Important factors include the magnetic force required, the size and shape of the formwork, the type of concrete element being produced, and the environmental conditions at the production site. Consult us before purchasing to help determine the best shuttering magnet for your needs.

What is the warranty period for your shuttering magnets?

Our shuttering magnets come with a 1-year warranty, provided they are used and maintained properly.

What is the typical delivery time for orders?

Standard products are typically dispatched within 10-15 days. Custom products may take 30-45 days. Sampling typically takes 5-7 days.

Do you provide OEM services?

Yes, we offer OEM services and have a dedicated R&D team to support customized solutions.

What are the shipping options for your products?

Samples are usually shipped via fast express, while bulk orders can be delivered by air or sea, depending on the customer’s preference.

Recommended articles and technical guidance

Other Magnetic Products

Other high quality magnetic products supported by Osencmag