Assembling a Halbach array is like trying to force angry cats into a bathtub. While wearing oven mitts. Blindfolded.

I’ve been there. And let me tell you: why are Halbach arrays so hard to assemble isn’t just a technical question—it’s a cry for help from anyone who’s tried to wrangle these magnetic beasts into submission.

Here’s the deal:

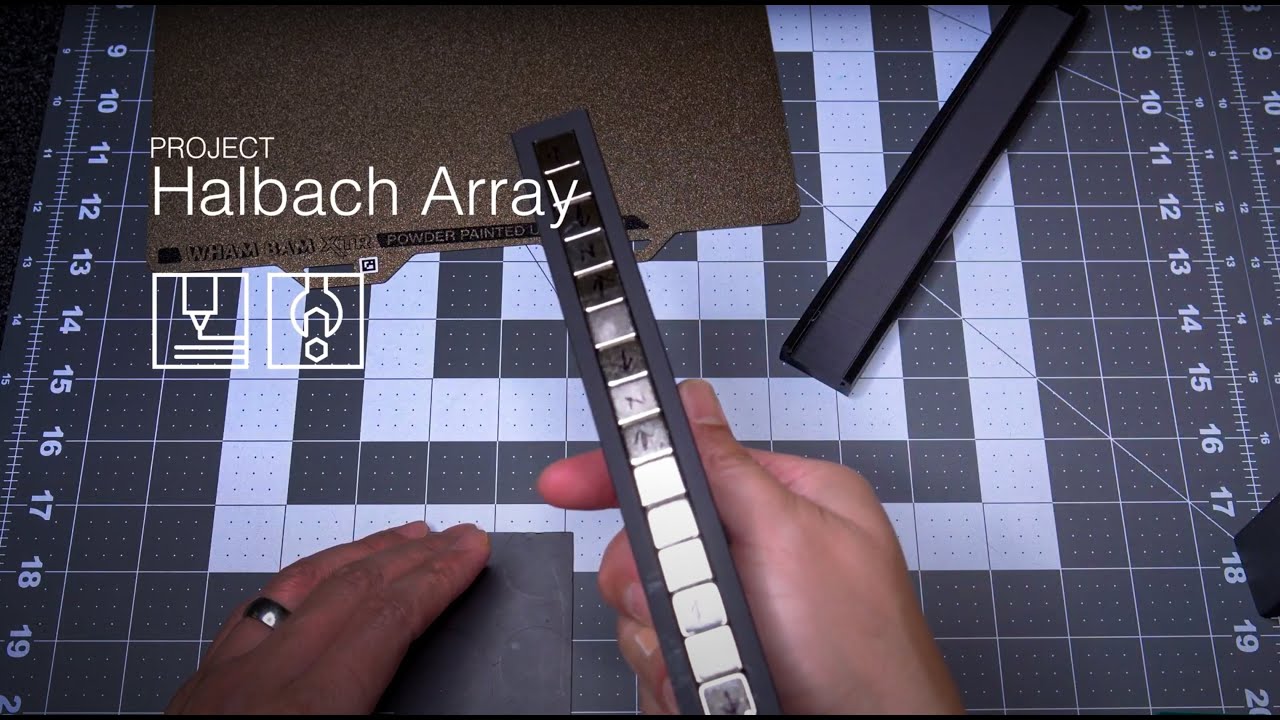

The finished Halbach array is an engineering masterpiece. It concentrates magnetic fields on one side while cancelling them on the other. Pretty sweet, right?

But getting there? That’s where things get messy. In this post, as a professional Halbach array manufacturer, I will share everything about the assembly of Halbach array.

Quick Summary:

- Halbach arrays are hard to assemble because strong, position-dependent repulsion and torque make placement, alignment, and retention mechanically aggressive.

- Risks include magnets snapping and shattering, adhesive failure, and performance loss from small misalignments.

- Effective approaches: containment jigs, staged epoxy or mechanical interference fits, hydraulic presses or progressive assembly, and two‑person teams.

- Consider professional assembly for arrays >10 magnets, high‑precision applications, or when the cost of failure is high.

The Physics Behind the Frustration

Let’s start with the basics.

In a normal magnet arrangement, you alternate North and South poles. They naturally attract. Easy peasy.

But Halbach arrays? They’re different.

Each magnet’s orientation rotates 90 degrees from its neighbor. This creates what physicists call a “one-sided flux” pattern.

Sounds cool in theory.

In practice? It’s magnetic mayhem.

Here’s why:

The magnets literally fight you. You’re forcing them into positions they hate. Like poles partially face each other, creating massive repulsive forces that can send a magnet flying across your workshop.

(Ask me how I know.)

Why Are Halbach Arrays So Hard to Assemble?

1. Fighting Invisible Forces

Remember playing with magnets as a kid? How they’d snap together or push apart?

Now imagine that force multiplied by 100.

That’s what you’re dealing with.

The repulsive forces in a Halbach array follow the inverse-square law. Translation: As you close the gap between magnets, the pushback increases exponentially.

One millimeter closer = 4x the force.

Half a millimeter? 16x.

The result: By the time you’re trying to place that fourth or fifth magnet, you’re essentially arm-wrestling an invisible gorilla.

2. The Dreaded “Snap” Risk

Neodymium magnets are strong. But they’re also brittle.

Like, really brittle.

Here’s what happens:

- Magnet slips from position

- Accelerates toward its neighbor at warp speed

- CRACK

- You now have expensive magnetic dust

I’ve shattered more N52 magnets than I care to admit. Each one sounds like a tiny gunshot when it breaks.

Pro tip: Always wear safety glasses. Magnetic shrapnel is no joke.

3. The Torque Tornado

Magnets don’t just push and pull.

They twist.

Picture trying to hold a bar of soap that’s desperately trying to flip 180 degrees while you’re squeezing it. That’s what assembling a Halbach array feels like.

Each magnet wants to spin into its “happy place”—which is exactly NOT where you need it to be.

Common solutions:

- Custom aluminum jigs

- 3D-printed alignment tools

- Brass fixtures

- A lot of patience (and maybe some creative swearing)

4. Adhesive Nightmares

You’d think superglue would save the day, right?

Wrong.

Here’s the problem:

Standard adhesives are under constant stress in a Halbach array. The magnets are perpetually trying to escape their prison. It’s like gluing together two springs that are compressed—eventually, something’s gotta give.

What actually works:

- High-strength structural epoxies

- Mechanical interference fits

- Metal sleeves or housings

- Prayer (results may vary)

5. Precision Requirements (Or: Why “Close Enough” Isn’t)

A Halbach array isn’t forgiving.

Even a 5-degree misalignment can:

- Create dead zones in your “strong” field

- Leak flux to the “cancelled” side

- Reduce overall efficiency by 30-40%

Think of it like building a house of cards. Except the cards are trying to fly away. And they weigh 50 grams each. And they’ll break your finger if you’re not careful.

Real-World Assembly Techniques (That Actually Work)

The Hydraulic Press Method

Big manufacturers don’t mess around.

They use:

- Custom machined “clamping skeletons”

- Hydraulic presses rated for thousands of pounds

- Precision alignment fixtures

- Teams of 2-3 people

Cost? Usually $50,000+ for the setup alone.

Not exactly DIY-friendly.

The Progressive Assembly Approach

This is what most of us mortals use:

- Start with a containment jig (aluminum or brass)

- Insert magnets one at a time

- Use temporary spacing blocks

- Apply epoxy in stages

- Pray nothing shifts during curing

Success rate? About 70% on a good day.

The “Magnetize After Assembly” Dream

Some folks try assembling with unmagnetized material, then magnetizing the whole array afterward.

Sounds smart, right?

The reality:

- Requires specialized magnetizing equipment

- Often results in uneven field strength

- Can damage the material structure

- Usually costs more than buying pre-magnetized pieces

Why Bother With Halbach Arrays At All?

After all this doom and gloom, you might wonder: Are they worth it?

Actually, yes.

Here’s what you get:

- 50% stronger fields on the working side

- Near-zero field on the back (great for sensitive electronics)

- Better efficiency than traditional arrays

- Unique applications (maglev trains, MRI machines, high-performance motors)

The performance gains are real. Just ask anyone using them in:

- Particle accelerators

- Electric vehicle motors

- Magnetic levitation systems

- Advanced medical equipment

Common Assembly Mistakes (Learn From My Pain)

Mistake #1: Using Magnets That Are Too Strong

“Go big or go home” doesn’t apply here.

Start with lower-grade magnets (N35 instead of N52) for practice. Your fingers will thank you.

Mistake #2: Rushing the Process

Halbach arrays punish impatience.

Take breaks. Work in stages. Don’t try to assemble a 20-magnet array in one session.

(Trust me on this one.)

Mistake #3: Skipping Safety Gear

Minimum requirements:

- Safety glasses

- Kevlar gloves

- Non-ferrous tools

- First aid kit nearby

Mistake #4: Working Alone

Two people make assembly 10x easier.

One person positions. One person holds. Both people keep their fingers.

The Future of Halbach Assembly

Good news: It’s getting easier.

New developments include:

- 3D-printed assembly guides with tighter tolerances

- Robotic assembly systems (finally!)

- Modular pre-assembled sections

- Better simulation software for planning

Some companies now offer pre-assembled Halbach arrays. Sure, they cost more. But so does reconstructive finger surgery.

Professional Assembly Services: When to Wave the White Flag

Sometimes, it’s worth admitting defeat.

Professional assembly makes sense when:

- You need arrays larger than 10 magnets

- Precision is critical (medical/aerospace applications)

- You value your sanity

- The cost of failure exceeds the assembly fee

Typical costs range from $500-$5000 depending on complexity.

The Bottom Line on Halbach Assembly

So, why are Halbach arrays so hard to assemble?

Because you’re literally fighting physics at every step. The same properties that make them amazing (concentrated fields, precise orientation) also make them a nightmare to put together.

But here’s the thing:

With the right tools, techniques, and expectations, it’s doable. Just don’t expect it to be easy. Or quick. Or fun.

Actually, scratch that last part. There’s a weird satisfaction when you finally get one assembled correctly. Like solving a Rubik’s cube. That fights back. And costs $300.

Remember: Every engineer who’s successfully assembled a Halbach array has a story about the one that got away (usually involving magnets flying across the room).

You’re not alone in the struggle. The magnetic wrestling match is real, but the results are worth it.

Just maybe start with a smaller array than you think you need. And buy extra magnets.

You’ll need them.