What is Mining Magnetic Coupling?

The mining magnetic coupling is a torque transmission technology that uses magnetic forces instead of physical connections to transfer power in harsh mining environments. Think of it as a “wireless” connection for rotating equipment—no touching parts, just magnetic fields doing all the work.

Here’s the thing:

Traditional mechanical couplings in mining operations take a beating. Between the dust, moisture, extreme temperatures, and constant vibration, they wear out fast. That’s where magnetic couplings come in. They solve these problems by eliminating physical contact altogether.

As a professional magnetic coupling manufacturer, I will share everything about mining magnetic coupling in this post.

How Mining Magnetic Couplings Actually Work

Let me break this down in simple terms.

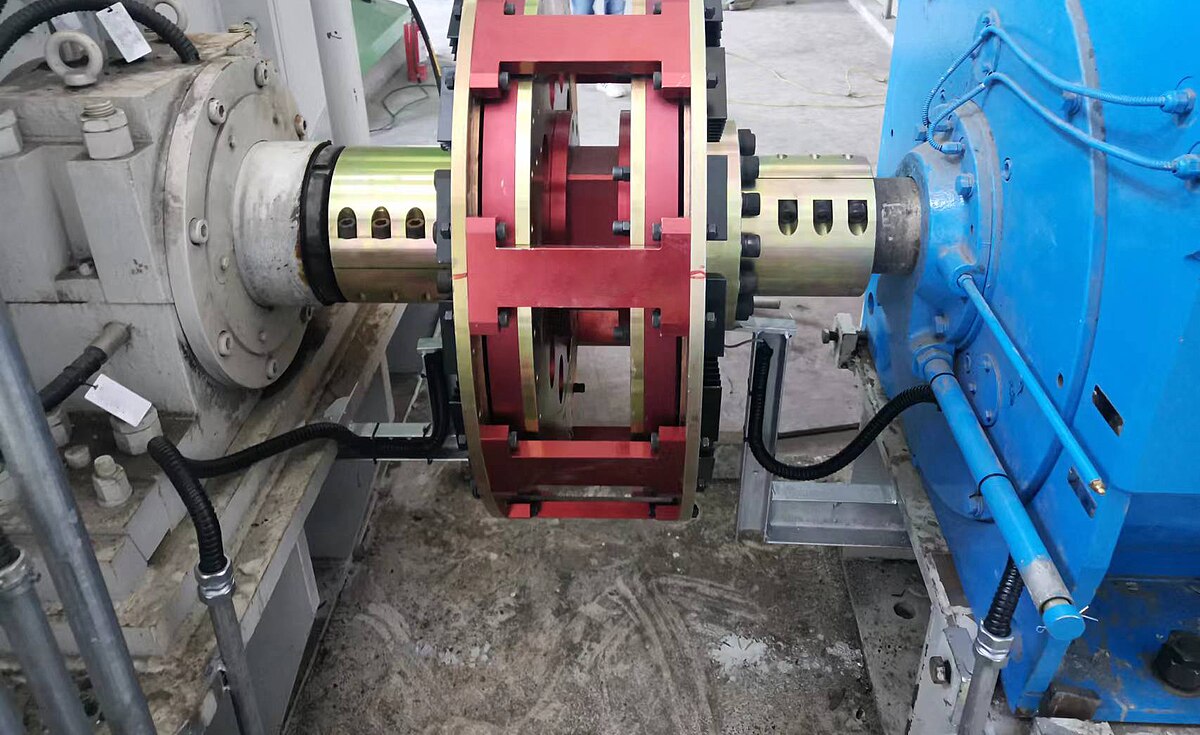

A mining magnetic coupling has two main parts:

- The driver side (connected to your motor)

- The driven side (connected to your equipment)

These two parts are separated by an air gap or containment barrier. When the motor spins the driver, its magnets create a rotating magnetic field. This field “grabs” the magnets on the driven side and pulls them along.

No chains. No gears. No physical contact whatsoever.

The coolest part? If your equipment jams or overloads, the magnetic connection simply slips. Your motor keeps running safely while the driven side stops. Try that with a mechanical coupling and you’ll be looking at damaged equipment (or worse).

Why Mining Operations Are Switching to Magnetic Couplings

I’ve seen mining companies slash their maintenance costs by 40% after switching to magnetic couplings. And that’s just the beginning.

Here’s what makes them perfect for mining:

Explosion-Proof by Design

Coal mines and chemical processing areas need equipment that won’t create sparks. Period.

Magnetic couplings eliminate friction—and therefore sparks—making them inherently safer in explosive atmospheres. They meet ATEX and MSHA standards without complex modifications.

Zero Leakage Problems

Traditional pump seals in slurry applications? They’re a nightmare.

Magnetic couplings use a containment barrier that completely separates the motor from the pump. No shaft seal means no leaks. Ever.

I talked to a copper mine engineer who said their slurry pump maintenance dropped 70% after installing magnetic drive pumps. That’s real money saved.

Built-In Overload Protection

Remember when I mentioned the coupling slips during overload? That’s not a bug—it’s a feature.

When your crusher hits an uncrushable object, a mechanical coupling might shear pins or damage gears. A magnetic coupling just decouples, protecting both your motor and equipment. Once you clear the jam, it automatically re-engages.

Real-World Mining Applications That Work

Let’s look at where these couplings really shine:

Conveyor Systems

Mining conveyors run 24/7. Any downtime costs thousands per hour.

Magnetic couplings provide:

- Soft starts that prevent belt slipping

- Vibration isolation that extends belt life

- Overload protection when material jams occur

One Australian iron ore mine reported their conveyor availability increased from 87% to 94% after retrofitting with magnetic couplings.

Crushers and Mills

These machines experience massive torque variations. A rock that’s too hard? Instant overload.

With magnetic couplings, the system automatically disconnects before damage occurs. No broken teeth, no burned-out motors, no emergency shutdowns.

Pumps and Slurry Handling

This is where magnetic couplings really dominate.

Pumping abrasive slurries destroys mechanical seals. But with a magnetically driven pump, there’s no seal to fail. The containment shell keeps everything separate.

Plus, you get:

- Zero contamination risk

- No seal water requirements

- Longer pump life

Ventilation Fans

Underground ventilation is literally life or death. You can’t afford fan failures.

Magnetic couplings eliminate the vibration that kills fan bearings. They also provide soft starts that reduce electrical demand during startup—important when you’re running on limited underground power.

The Technical Specs That Matter

Now, let’s get into the numbers that mining engineers actually care about:

Torque Capacity: Modern mining magnetic couplings handle up to 25,000 Nm. That’s enough for even the biggest equipment.

Efficiency: Greater than 98% at full load. You’re not wasting power.

Temperature Range: -40°C to +300°C (depending on magnet type). They work in frozen arctic mines and hot desert operations.

Air Gap Tolerance: Typically ±0.5mm. Precise, but not impossibly tight.

Common Concerns (And Why They’re Overblown)

“But They’re More Expensive!”

Yes, magnetic couplings cost more upfront. Sometimes 2-3x more than mechanical alternatives.

But here’s what that extra cost gets you:

- 50-70% reduction in maintenance costs

- 90% fewer unplanned shutdowns

- 5-10 year service life (vs 1-2 years for mechanical in harsh conditions)

Do the math. The payback period is usually under 18 months.

“What About Torque Limitations?”

Early magnetic couplings struggled with high-torque applications. Not anymore.

Modern rare-earth magnets (neodymium and samarium cobalt) provide incredible torque density. I’ve seen 800kW systems running flawlessly in mining applications.

“Are They Difficult to Install?”

Actually, they’re easier than mechanical couplings.

Why? Because they tolerate misalignment better. You don’t need laser-perfect shaft alignment. The magnetic field compensates for minor angular and parallel misalignment.

How to Choose the Right Mining Magnetic Coupling

Not all magnetic couplings are created equal. Here’s your selection checklist:

Step 1: Calculate Your Torque Requirements

- Normal operating torque

- Peak torque during startup

- Overload conditions

Add a 25% safety factor for mining applications.

Step 2: Check Environmental Conditions

- Temperature extremes

- Chemical exposure

- Dust and moisture levels

Step 3: Verify Safety Certifications

- ATEX ratings for explosive atmospheres

- MSHA approval for US coal mines

- Local mining regulations

Step 4: Consider Integration Requirements

- Shaft sizes and configurations

- Available space

- Retrofit vs new installation

Installation Best Practices

I’ve seen perfectly good magnetic couplings fail because of poor installation. Don’t let that happen to you.

Critical Installation Steps:

- Check Magnet Polarity: Sounds obvious, but reversed magnets won’t transmit torque

- Set Air Gap Precisely: Use feeler gauges, not eyeballs

- Verify Alignment: Even though they’re forgiving, proper alignment maximizes efficiency

- Install Safety Shields: Magnetic fields are strong—protect personnel and equipment

Pro Tip: Temperature Compensation

Magnets lose strength at high temperatures. If you’re operating above 80°C, size up your coupling to compensate. The manufacturer’s derating curves will show you exactly how much.

Future Trends in Mining Magnetic Coupling Technology

The technology keeps improving. Here’s what’s coming:

Smart Monitoring Integration

New couplings include built-in sensors for:

- Torque monitoring

- Temperature tracking

- Vibration analysis

- Predictive maintenance alerts

Imagine knowing your coupling is approaching overload before it happens.

Advanced Materials

Researchers are developing new magnet materials that maintain strength above 400°C. This opens up applications in extreme mining environments that were previously impossible.

Modular Designs

Standardized, interchangeable components that reduce inventory costs and simplify maintenance. One coupling design that fits multiple applications.

Making the Switch: A Practical Approach

If you’re considering magnetic couplings for your mining operation, start small:

- Pilot Program: Choose one critical application (like a problematic slurry pump)

- Document Everything: Track maintenance costs, downtime, and performance

- Calculate ROI: Use real data from your operation

- Scale Up: Expand to other applications based on proven results

The Bottom Line on Mining Magnetic Couplings

Look, mining is tough on equipment. Always has been, always will be.

But that doesn’t mean you have to accept constant maintenance, frequent failures, and safety risks. Magnetic coupling technology offers a proven solution that’s transforming mining operations worldwide.

Yes, they cost more initially. But when you factor in reduced maintenance, improved safety, and increased uptime, they’re a smart investment.

The technology is mature. The benefits are proven. And the mining industry is adopting them rapidly.

So, what is mining magnetic coupling? It’s the future of power transmission in mining—delivering reliability, safety, and efficiency in the world’s harshest operating environments.