Table of Contents

What is Magnetic Coupling?

What is magnetic coupling? It’s a technology that transfers torque from one shaft to another without any physical contact. Instead of gears meshing together or belts connecting pulleys, magnetic coupling uses powerful magnetic fields to transmit power across an air gap.

Think of it like this:

You’ve got two magnets on your fridge. When you move one close to the other, they either attract or repel each other, right? Magnetic coupling works on the same principle – but with way more precision and power.

And here’s the kicker:

This contactless power transmission is revolutionizing industries from chemical processing to underwater robotics. In fact, the global magnetic coupling market is expected to hit $1.2 billion by 2028.

But I’m getting ahead of myself.

In this guide, as a professional magnetic coupling manufacturer, I’ll break down everything you need to know about magnetic coupling technology. Including how it works, the different types available, and why more engineers are choosing it over traditional mechanical couplings.

Let’s dive in.

How Magnetic Coupling Actually Works

Here’s where things get interesting.

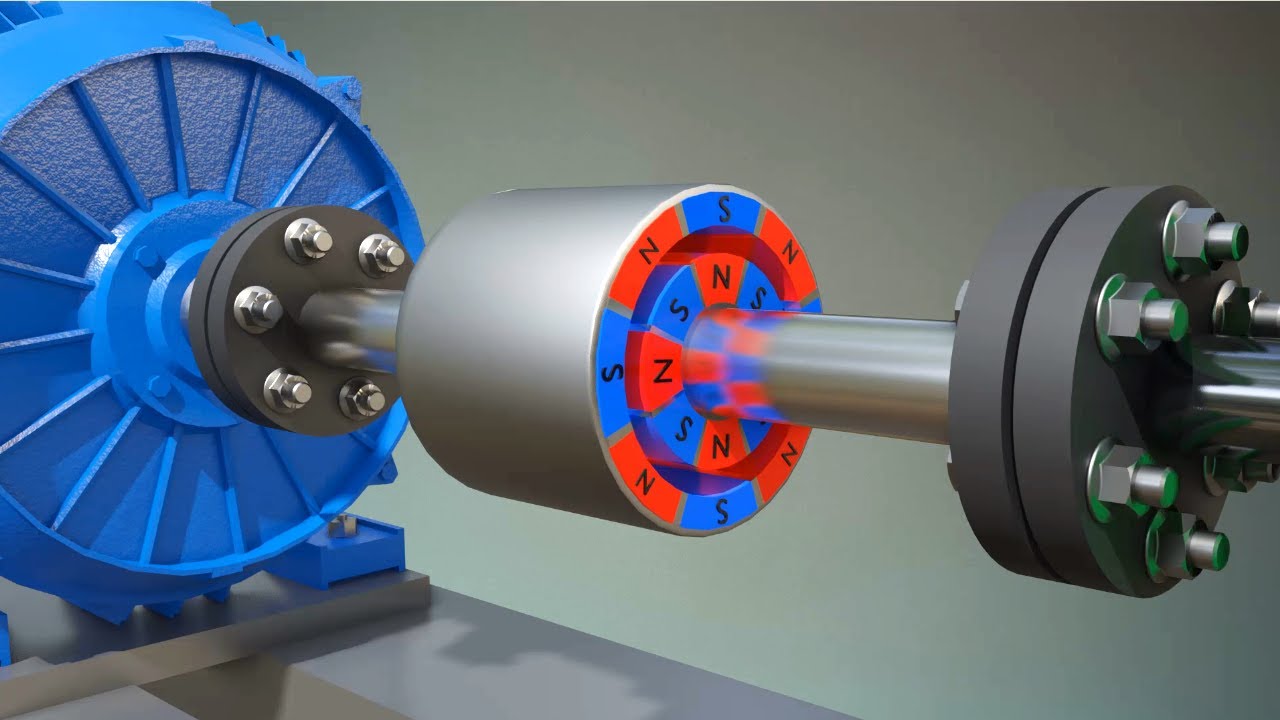

A magnetic coupling consists of two main parts: a driver (connected to your motor) and a follower (connected to whatever you’re trying to spin).

Both parts have powerful permanent magnets arranged in a specific pattern. When the driver rotates, its magnetic field interacts with the follower’s magnets. This interaction creates torque that makes the follower spin in sync with the driver.

The best part?

There’s zero physical contact between the two halves. They can be separated by air, a solid barrier (like a stainless steel wall), or even a vacuum.

I recently visited a chemical plant that uses magnetic drive pumps. The engineer showed me how the motor sits completely outside the sealed pump chamber. The magnetic coupling transfers power through a solid containment shell, keeping nasty chemicals from leaking out.

Pretty cool, right?

The Science Behind the Magic

Now, you might be wondering:

“How strong can these magnetic forces really be?”

The answer: incredibly strong.

Modern magnetic couplings use rare earth magnets (usually neodymium) that can transmit serious torque. We’re talking about systems that handle hundreds of horsepower without breaking a sweat.

The torque capacity depends on several factors:

- Magnetic material strength (neodymium beats ferrite every time)

- Number of magnetic poles (more poles = more torque)

- Air gap distance (smaller gaps transfer more power)

- Temperature (magnets lose strength when hot)

- Coupling diameter (bigger is usually better)

Here’s something that blew my mind:

The magnetic field strength follows an inverse square law. That means if you double the distance between the magnets, you get only 1/4 of the force. This is why precision engineering is crucial for magnetic coupling design.

Types of Magnetic Couplings (And When to Use Each)

Not all magnetic couplings are created equal.

Let me break down the main types you’ll encounter:

Synchronous Magnetic Couplings

These are the workhorses of the magnetic coupling world.

The driver and follower rotate at exactly the same speed (hence “synchronous”). They use permanent magnets on both sides and maintain a 1:1 speed ratio.

You’ll find these in:

- Chemical pumps

- Mixing equipment

- Medical devices

- Food processing machinery

I’ve seen synchronous couplings handle everything from tiny lab equipment spinning at 10,000 RPM to massive industrial mixers churning viscous materials.

Eddy Current Couplings

Now these are different.

Instead of permanent magnets on both sides, eddy current couplings use magnets on one side and a conductor (like copper or aluminum) on the other. When the magnets spin, they induce electrical currents in the conductor. These currents create their own magnetic field, which generates torque.

The cool thing about eddy current couplings?

They naturally allow controlled slip between input and output speeds. This makes them perfect for:

- Soft-start applications

- Variable speed drives

- Overload protection systems

Hysteresis Couplings

These are the precision instruments of the magnetic coupling family.

They use a special magnetic material that “remembers” its magnetic state (that’s the hysteresis part). This creates incredibly smooth torque transmission with zero cogging.

Filmmakers use hysteresis couplings in camera equipment because they’re so smooth. No jerky movements means buttery smooth footage.

Why Magnetic Coupling Beats Traditional Methods

Let me tell you a story.

A pharmaceutical company I worked with had a problem. Their traditional sealed pumps kept failing, leaking expensive (and hazardous) chemicals. Each failure meant:

- Production downtime

- Cleanup costs

- Potential safety incidents

- Regulatory headaches

They switched to magnetic coupling pumps.

The result? Zero leaks in three years of operation. Their maintenance costs dropped by 75%.

But leak prevention is just the beginning. Here’s what else magnetic coupling brings to the table:

Zero Wear and Tear

No contact means no friction. No friction means no wear. I’ve seen magnetic couplings run for decades with zero maintenance beyond occasional bearing replacement.

Built-in Overload Protection

If your equipment jams, a mechanical coupling might snap, strip gears, or burn out the motor. A magnetic coupling? It just slips harmlessly until you fix the problem.

Vibration Isolation

The magnetic connection acts like a cushion, absorbing vibrations that would normally transfer through a solid shaft. Your equipment runs quieter and lasts longer.

Easy Alignment

Unlike rigid couplings that demand perfect shaft alignment, magnetic couplings are forgiving. A few degrees of misalignment? No problem.

Real-World Applications That’ll Blow Your Mind

Magnetic coupling technology shows up in some surprising places.

Chemical Processing Plants

This is the big one. When you’re pumping acids, solvents, or other nasty chemicals, seal failure isn’t just expensive – it’s dangerous. Magnetic drive pumps eliminate dynamic seals entirely.

One refinery I consulted for replaced 50 traditional pumps with mag-drive units. Their fugitive emissions dropped to nearly zero, and they saved $2 million annually in maintenance and environmental compliance costs.

Underwater Robotics

Here’s a challenge: How do you transfer power to a propeller on a submarine without letting water in?

Answer: Magnetic coupling.

The motor stays inside the dry hull. The propeller sits outside in the water. A magnetic coupling transfers power through the pressure-resistant hull. No rotating seals to fail at depth.

Clean Room Manufacturing

Semiconductor fabs and pharmaceutical clean rooms can’t tolerate any contamination. Traditional couplings generate particles from wear. Magnetic couplings? Particle-free operation.

Food and Beverage

FDA regulations are strict about equipment cleanliness. Magnetic coupling mixers have no shaft seals where bacteria can hide. They’re easier to clean and maintain sterile conditions.

The Hidden Costs (And How to Avoid Them)

I’ll be straight with you:

Magnetic couplings cost more upfront than mechanical alternatives. Sometimes 2-3x more.

But here’s what the price tag doesn’t show:

Reduced Maintenance

No seals to replace. No alignment issues. No worn couplings to swap out. One chemical plant calculated their mag-drive pumps paid for themselves in 18 months through maintenance savings alone.

Energy Efficiency

High-quality magnetic couplings are 98%+ efficient. Over years of operation, that efficiency advantage adds up to serious energy savings.

Prevented Disasters

What’s the cost of a chemical spill? Lost production during cleanup? Environmental fines? Magnetic coupling prevents these expensive “surprises.”

Design Considerations That Make or Break Performance

Getting magnetic coupling right requires attention to detail.

Temperature Management

Remember how I mentioned magnets lose strength when hot? It’s a big deal. Neodymium magnets start losing strength around 80°C (176°F). If your application runs hot, you need:

- Samarium cobalt magnets (good to 300°C)

- Cooling provisions

- Thermal barriers between hot processes and magnets

Torque Calculations

Under-size your coupling and it’ll slip constantly. Over-size it and you’re wasting money. The sweet spot? Design for 1.5-2x your normal operating torque to handle startup surges and occasional overloads.

Material Compatibility

The containment shell (if you use one) needs to be non-magnetic. Stainless steel 316 is popular, but Hastelloy handles more aggressive chemicals. For highest efficiency, consider non-metallic options like PEEK or ceramic.

Common Mistakes (And How to Dodge Them)

I’ve seen plenty of magnetic coupling installations go wrong. Here are the big ones:

Ignoring Eddy Current Heating

When you spin magnets near a conductor, you generate heat. Lots of it. If your containment shell is metallic, you need to account for this heating in your design.

Forgetting About Axial Forces

Magnetic couplings don’t just create rotational forces – they also pull the two halves together axially. Your bearings need to handle these loads.

Skimping on Magnet Quality

Cheap magnets = poor performance and short life. Stick with reputable suppliers and verify the magnetic properties.

Future Trends in Magnetic Coupling Technology

The magnetic coupling industry isn’t standing still.

Here’s what’s coming:

Smart Couplings

Embedded sensors monitoring temperature, vibration, and slip. Predictive maintenance becomes reality when your coupling tells you it needs attention.

Advanced Materials

New magnetic materials promise higher temperature operation and stronger fields. Carbon fiber containment shells reduce eddy current losses.

Additive Manufacturing

3D printed magnetic assemblies allow complex geometries impossible with traditional manufacturing. Custom solutions become economically viable for smaller applications.

Making the Right Choice for Your Application

So, should you use magnetic coupling?

Ask yourself:

- Do I need zero leakage?

- Is maintenance access difficult?

- Am I handling hazardous materials?

- Do I need overload protection?

- Is vibration isolation important?

If you answered yes to any of these, magnetic coupling deserves serious consideration.

But remember:

Not every application needs magnetic coupling. Simple water pumps? Probably overkill. But when reliability, safety, or cleanliness matter, the extra investment pays dividends.

The Bottom Line

What is magnetic coupling? It’s a proven technology that uses magnetic fields to transmit power without physical contact. From preventing chemical leaks to enabling underwater propulsion, magnetic coupling solves problems that traditional mechanical connections can’t touch.

The technology continues evolving, with smarter designs and stronger materials expanding its capabilities. Whether you’re designing a new system or upgrading existing equipment, understanding magnetic coupling opens up possibilities for more reliable, safer, and cleaner operations.

Sure, the upfront cost is higher. But when you factor in reduced maintenance, prevented failures, and operational advantages, magnetic coupling often delivers the lowest total cost of ownership.

That’s the real magic of magnetic coupling – turning a simple magnetic principle into industrial solutions that just work, year after year, without the headaches of traditional mechanical systems.