In the industrial sector, durability is key. Our large industrial wear-resistant rare earth magnetic drums are designed for use in the most challenging industrial conditions. I work closely with customers to customize features such as coatings and shell materials, and select wear-resistant options. Magnetic strength and high temperature resistance can be customized to meet the specific needs of your operation. With flexible sizes and customized feeding methods, our industrial magnetic drums will improve your material separation efficiency. Whether in mining, recycling or heavy industrial use, our magnetic drums provide reliable performance and durability, allowing you to focus on productivity without compromising quality. Partner with us to transform your material processing business.

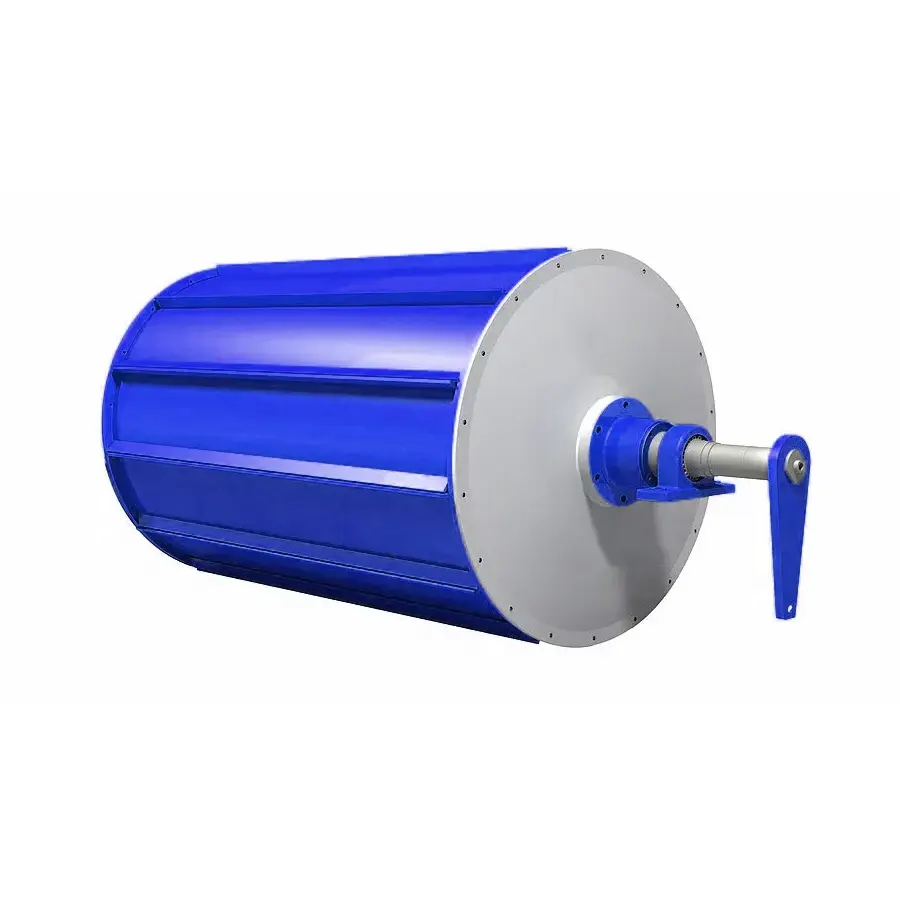

Large industrial wear-resistant rare earth magnetic drum

- Magnet Type: N35-N52 rare earth neodymium magnets, with superior magnetic strength and durability, provide powerful separation capabilities.

Size Options: Custom sizes are available, generally ranging from 18 inches to 60 inches in diameter for large industrial applications.

Core Orientation: Customize the core orientation based on the feed system to meet the established workflow of the production line.

Housing Materials: Typically made of heavy-duty materials such as stainless steel, carbon steel, or hardened steel to withstand severe wear and tear.

Coating Options: Available coatings include industrial-grade epoxy, rubber coating for shock absorption, and zinc coating for corrosion protection.

Applications: Suitable for heavy-duty industries such as mining, recycling and scrap metal processing, providing reliability and performance under demanding conditions.

Related products

-

Magnetic Drum

Construction metal aggregate magnetic drum separator

-

Magnetic coupling

OFS Series High Torque Magnetic Coupling

-

Magnetic coupling

BX Series Torque limited mining magnetic coupling