Ever wondered how pumps can move dangerous chemicals without a single drop leaking out? Or how medical equipment transmits power through sealed barriers without contamination?

The answer is magnetic coupling working principle – a clever engineering solution that’s quietly revolutionizing industries from pharmaceuticals to food processing.

Here’s the deal:

Traditional mechanical couplings have a fatal flaw. They need physical contact to work. That means seals that wear out, maintenance headaches, and the constant risk of leaks.

But magnetic couplings? They transmit torque through thin air (or even solid walls) using nothing but magnetic fields.

Pretty cool, right?

In this guide, as a professional magnetic coupling manufacturer, I’ll break down exactly how magnetic couplings work, why they’re becoming the go-to choice for critical applications, and how you can determine if they’re right for your needs.

Let’s dive in.

Table of Contents

What Exactly Is a Magnetic Coupling?

Think of a magnetic coupling as an invisible handshake between two shafts.

Instead of gears meshing together or keys locking into place, you have magnets doing all the heavy lifting. One shaft spins, its magnets create a rotating magnetic field, and boom – the other shaft follows along like it’s connected by an invisible rope.

The beauty of this system?

Zero physical contact.

That means no wear, no friction, and most importantly – no path for leaks.

I remember the first time I saw a magnetic coupling in action at a chemical plant. The engineer showed me how they were pumping sulfuric acid through a completely sealed system. No shaft seals. No potential leak points. Just magnets doing their thing through a stainless steel barrier.

Mind = blown.

Magnetic Coupling Working Principle

Let me break down the magnetic coupling working principle into bite-sized pieces.

The Basic Components

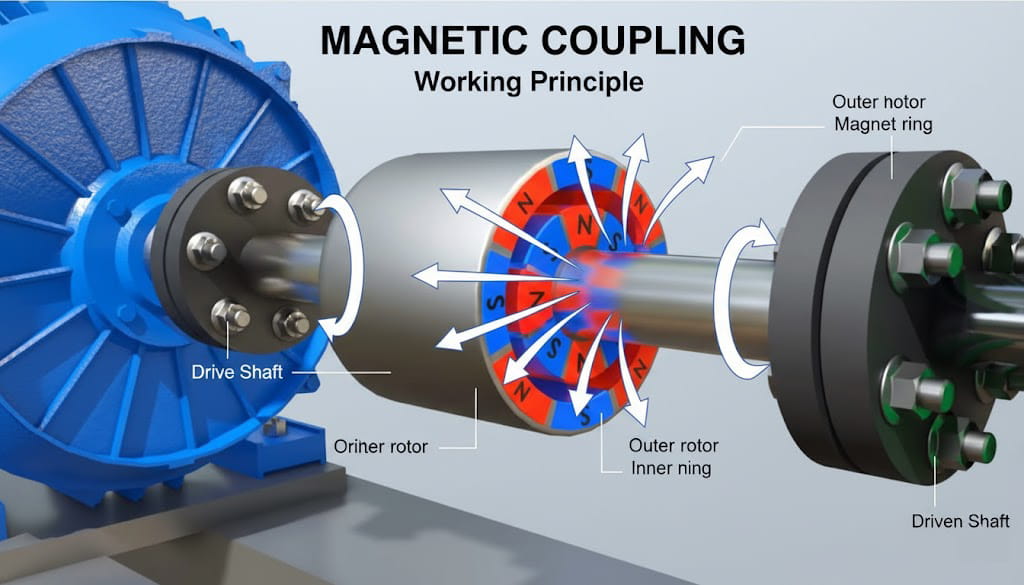

Every magnetic coupling has four main parts:

- Outer rotor (connected to your motor)

- Inner rotor (connected to your pump or equipment)

- Permanent magnets (the real heroes here)

- Containment shell (the barrier between them)

Here’s where it gets interesting:

The magnets on both rotors are arranged in a specific pattern – alternating north and south poles around the circumference. When the outer rotor spins, its magnetic field reaches through the containment shell and grabs onto the inner rotor’s magnets.

It’s like having invisible teeth that mesh perfectly without touching.

The Physics Behind the Magic

When your motor turns the outer rotor, something fascinating happens.

The rotating magnetic field creates what engineers call “flux linkage” with the inner rotor. This isn’t some weak attraction – we’re talking serious torque transmission here.

The strength depends on three key factors:

- Magnet strength (usually rare earth magnets like neodymium)

- Air gap size (smaller = stronger coupling)

- Number of magnetic poles (more poles = smoother operation)

Pro Tip: The torque capacity of a magnetic coupling is directly proportional to the magnetic field strength and inversely proportional to the gap between magnets. That’s why precision engineering matters so much.

The Secret Sauce: Synchronous Operation

Here’s something that blows people’s minds:

Magnetic couplings operate synchronously.

That means when the outer rotor turns at 1,800 RPM, the inner rotor turns at exactly 1,800 RPM. No slippage. No lag. Perfect 1:1 rotation.

But wait, there’s more.

If you apply too much load (exceeding the coupling’s torque capacity), the magnets temporarily “slip” out of sync. Instead of breaking something expensive, the coupling just decouples magnetically.

Once the overload is removed? They snap back into synchronous operation like nothing happened.

It’s basically built-in overload protection. How’s that for smart engineering?

Real-World Applications That’ll Surprise You

You’d be amazed where magnetic couplings show up.

Chemical Processing Plants

Remember that sulfuric acid example? That’s just the tip of the iceberg.

Chemical plants use magnetic drive pumps for:

- Hydrochloric acid

- Sodium hydroxide

- Volatile organic compounds

- Pretty much any nasty chemical you can think of

The containment shell provides hermetic sealing – zero leakage, guaranteed.

Food and Beverage Industry

Ever wonder how they pump chocolate syrup or tomato paste without contamination?

Magnetic couplings, my friend.

No shaft seals means no lubricants leaking into your food. Plus, they’re easy to clean and sanitize. Win-win.

Medical Equipment

MRI machines, blood pumps, pharmaceutical mixers – they all rely on magnetic couplings for contamination-free operation.

In fact, I recently learned that some artificial heart pumps use magnetic coupling technology. When you’re pumping blood, the last thing you want is mechanical wear particles floating around.

Nuclear Power Plants

This one’s wild:

Nuclear facilities use magnetic couplings to handle radioactive materials. The non-contact power transmission means workers stay safe behind barriers while still controlling pumps and mixers.

The Hidden Benefits Nobody Talks About

Sure, everyone mentions “no leaks” and “low maintenance.”

But there’s more to the story.

Vibration Isolation

Because there’s no mechanical connection, magnetic couplings naturally dampen vibrations. Your motor’s vibrations don’t transfer directly to your pump.

Result? Quieter operation and longer equipment life.

Misalignment Tolerance

Traditional couplings demand perfect alignment. Even small misalignments cause wear and efficiency losses.

Magnetic couplings? They’re way more forgiving. The magnetic field can handle minor angular and parallel misalignments without breaking a sweat.

Energy Efficiency (With a Catch)

Here’s where it gets nuanced.

Magnetic couplings can be incredibly efficient – often 98% or higher. But there’s a catch: eddy currents.

When magnetic fields pass through conductive materials (like metal containment shells), they create eddy currents. These currents generate heat and waste energy.

The solution? Non-metallic containment shells or special alloys that minimize eddy current losses.

Common Misconceptions Debunked

Let’s clear up some confusion about magnetic couplings.

“They’re Only for Small Applications”

Wrong.

I’ve seen magnetic couplings handling 500+ horsepower. Sure, they’re more common in smaller applications, but technology has come a long way.

“They’re Too Expensive”

Initial cost? Yeah, they’re pricier than mechanical couplings.

But factor in:

- Zero seal replacements

- No downtime for seal maintenance

- No environmental cleanup from leaks

- Longer equipment life

Suddenly that ROI looks pretty good.

“They Lose Strength Over Time”

Modern rare earth magnets are incredibly stable. With proper temperature management, they’ll maintain their strength for decades.

The key? Don’t exceed their maximum operating temperature. Neodymium magnets start losing strength above 80°C (though special grades can handle up to 200°C).

Design Considerations That Make or Break Performance

If you’re thinking about magnetic couplings for your application, pay attention to these factors.

Temperature Limits

This is crucial.

Every magnet material has a maximum operating temperature. Exceed it, and you’ll permanently damage the magnets.

- Standard neodymium: 80°C

- High-temp neodymium: 150°C

- Samarium cobalt: 300°C+

Choose wisely based on your application.

Torque Requirements

Calculate your peak torque needs, then add a safety factor.

Remember: magnetic couplings provide overload protection, but you don’t want them slipping during normal operation.

Chemical Compatibility

The containment shell and magnet coatings must resist your process fluid. Common materials include:

- Hastelloy (for extreme corrosion resistance)

- 316L stainless steel (good all-around choice)

- PEEK or PTFE linings (for ultimate chemical resistance)

Speed Limitations

Higher speeds mean higher eddy current losses. Most magnetic couplings work best below 3,600 RPM, though special designs can handle much higher speeds.

Troubleshooting Common Issues

Even the best technology has quirks. Here’s how to handle common magnetic coupling challenges.

Excessive Heat Generation

Symptoms: Hot containment shell, reduced efficiency

Causes:

- Eddy currents (switch to non-metallic shell)

- Insufficient cooling flow

- Oversized coupling for the application

Loss of Torque

Symptoms: Slipping, inability to maintain speed

Causes:

- Demagnetization from overheating

- Excessive air gap (check alignment)

- Mechanical interference

Noise or Vibration

Symptoms: Unusual sounds, vibration despite magnetic isolation

Causes:

- Magnetic imbalance

- Foreign material between rotors

- Bearing issues

The Future of Magnetic Coupling Technology

The industry isn’t standing still.

Here’s what’s coming in 2025 and beyond:

Advanced Materials

New magnet materials promise higher temperature resistance and stronger magnetic fields. We’re talking about exotic rare earth combinations that could double current torque capacities.

Smart Couplings

Imagine magnetic couplings with built-in sensors monitoring:

- Temperature

- Torque transmission

- Vibration levels

- Magnetic field strength

Real-time data for predictive maintenance? Yes, please.

Additive Manufacturing

3D printing is revolutionizing coupling design. Complex geometries that optimize magnetic flux paths while minimizing weight? It’s already happening in aerospace applications.

Making the Right Choice

So, should you switch to magnetic couplings?

Ask yourself:

- Do you handle hazardous fluids? If yes, magnetic couplings are a no-brainer.

- Is contamination a concern? Zero leakage means zero contamination.

- What’s your maintenance budget? Higher upfront cost, but way lower lifecycle costs.

- Can you handle the design constraints? Temperature limits, speed restrictions, etc.

If you answered yes to the first three and can work within the constraints, magnetic couplings will transform your operation.

The Bottom Line

The magnetic coupling working principle represents a fundamental shift in how we think about power transmission.

By eliminating physical contact between driving and driven components, we’ve solved age-old problems of leakage, wear, and contamination. The technology uses permanent magnets to create an invisible but incredibly strong connection through barriers – delivering torque efficiently while maintaining complete isolation.

Sure, they’re not perfect for every application. But for industries where reliability, safety, and cleanliness matter most? They’re game-changers.

The beauty lies in the simplicity: magnets attracting across a gap, turning synchronously, protecting your equipment from overloads, and doing it all without a single mechanical seal.

That’s the magnetic coupling working principle in action – elegant engineering solving real-world problems.