Magnetic drum filter drum manufacturer

Magnetic Drum Separators can efficiently separate and recover metal materials. The magnetic drum assembly helps the entire separation system to achieve more efficient work efficiency. As a professional magnetic solution provider, we can provide you with customized solutions to improve your recovery efficiency.

Custom options for Magnetic Drum Separators

Dimensions and specifications

We provide customized dimensions according to the specific needs of customers, including magnetic drum diameter and working length, to ensure efficient operation in different working spaces.

Magnet materials

Choose from a variety of high-performance magnet materials, including neodymium and ceramic. According to the magnetic strength required for the separation project, adapt the corresponding strong magnetic grade permanent magnet to achieve the required separation efficiency.

Shell metal

Our drums support different metal materials, including: iron, cold rolled steel, alloy steel, stainless steel, aluminum alloy and other options. To help customers cope with various complex operating environments to provide reliability.

Coating options

Choose from a variety of coatings (nickel, zinc, chrome, etc.) to enhance the corrosion resistance and longevity of the magnets inside your Magnetic Drum Separators to handle the working conditions of underground mines or specific industries.

Feed Method Integration

We support the customization of the Magnetic Drum magnetic structure according to the feed method of the customer's separation system, facilitating seamless integration with existing separation equipment, reducing unnecessary modifications and ensuring smooth operation.

Why choose us as your magnetic drum concentrator supplier

We have been deeply involved in the magnetic technology industry for more than 20 years and are a trusted manufacturer of magnetic components. The magnetic drum manufacturing workshop is equipped with state-of-the-art machines and a team of experts, allowing us to handle mass production accurately and efficiently.

The entire manufacturing process is ISO 9001 certified, using high-grade materials such as neodymium magnets and strong metal alloys to manufacture the drum. Each magnetic drum follows a strict quality control process to meet the actual needs of customers.

We have successfully cooperated with leading companies in multiple industries in the past, delivering more than 10,000 magnetic drums each year with a customer satisfaction rate of up to 99%. We and our supply chain network guarantee reliable delivery times and competitive prices. Contact us today to discuss your magnetic drum separator needs.

What are magnetic drum?

Magnetic Drum Separators are a type of material separation equipment widely used in various industries, and the magnetic drum is an essential component of the magnetic separator. The magnetic drum looks similar to a cylindrical drum, and the magnetic force inside the drum during rotation can reliably attract or separate metal particles from slurries, granules or powders.

Magnetic drums can help differentiate and sort materials with high iron content in a very convenient way during the flow process. This makes it invaluable in recycling, mining and manufacturing operations. Whether it is processing metal scrap or purifying raw materials, magnetic drums can simplify the work by effectively filtering out unwanted contaminants.

Main advantages of magnetic drums

Main components of magnetic drums

- Separation efficiency: Magnetic drums provide continuous separation, which means that they can run non-stop to extract metal particles from bulk materials and minerals.

- Versatility: Magnetic drums can be used in different industries from mining operations, waste recycling to industrial manufacturing.

- Economical and efficient: By using magnetic drums in the separation process, labor costs can be greatly reduced and material waste can be minimized.

Magnetic drums are composed of two parts--

- Magnetic system: The core of each magnetic drum is its internal magnetic system. Magnetic systems can be either permanent magnets or electromagnets. Permanent magnets provide continuous performance without the need for power, while electromagnets provide adjustable magnetic strength, giving you the flexibility to choose based on your material processing needs.

- Drum Shell: The outer shell of the drum is usually made of stainless steel and rotates around a central fixed magnetic core, designed to protect the internal magnetic core while separating materials. When separating abrasive materials, the drum shell can wear out. Therefore, in addition to custom high-strength alloy shells for specific industries, we also support custom removable drum shell designs so that customers can replace the shell themselves. This greatly increases the life of the permanent magnet drum and the entire equipment.

Magnetic drums play a key role in optimizing the separation process in various industries, and by investing in high-quality custom magnetic drums, the separation process can be greatly enhanced. If you are considering using magnetic drums to enhance your operations, contact Osencmag for expert advice and high-quality custom solutions. Our team is committed to providing expert guidance and support throughout the customization process to ensure that you receive a product that exceeds your expectations.

How does a magnetic drum separator work?

Magnetic Drum Separators use a magnetic drum to separate ferrous from non-ferrous materials. This process may sound complicated, but once you understand how the magnetic drum itself works within the separator, the principle is simple.

The magnetic drum is fixed at the heart of the entire separation process. As the raw materials pass over the rotating drum, any non-ferrous materials that are not affected by the magnets will naturally fall off the drum and enter the “cleaned” flow line. Any ferrous tramp metal (usually iron or steel) will be captured by the magnetic field and temporarily detained on the drum surface until it is carried out of the magnetic field and transported to another “ferrous material discharge area”.

Of course, in addition to the regular rotation separation principle of the magnetic drum, there is also a mobile extraction separation method. The extraction drum rotates in the opposite direction to the supply conveyor flow line and is arranged above the feed discharge port. The magnetic drum extracts the magnetic particles from the feed port and then rotates to transport them upward to a separate separation area.

Both types of magnetic drums use the principle and working process of magnetic attraction. Usually, the “natural rotation and falling” separation method is often used in scenes where the raw material particle size is smaller and more uniform. The “mobile extraction” separation method magnetic drum can be used to extract larger volumes of metal materials due to its higher magnetic performance, and it can ensure the cleanliness of the metal product.

The effectiveness of the magnetic drum depends largely on its design and magnetic strength. Different industries require different magnetic strengths, and customization is the key. We can adjust the size, magnetic force and coating of the magnetic drum according to the actual feeding method of the customer. Whether you are separating metals in a high-temperature environment or handling abrasives, our magnetic drums are durable and reliable.

Step by step process:

- Material Feed: The raw materials usually contain a mixture of ferrous and non-ferrous metal components and are fed to a conveyor belt or directly to the drum.

- Magnetic separation: As the drum rotates, the magnetic field pulls the ferrous material to the drum surface. These particles are attracted to the drum while the rest of the material falls off.

- Discharge: As the drum continues to rotate, the magnetic material is carried away from the main material flow. Once they reach a point outside the drum magnetic field, they fall into a separate collection area.

- Non-magnetic materials: At the same time, the non-magnetic particles are not affected by the drum magnetic field and continue to travel along their original path, separating from the ferrous material.

Application scenarios of magnetic drum separation.

Magnetic drum separators play a vital role in a variety of industries. Whether it’s recycling, mining, food processing, and construction aggregates, these machines help you effectively separate ferrous materials from nonferrous materials.

- Recycling Industry: When breaking down automotive, electrical, or electronic waste in the recycling industry, magnetic drums pull valuable metals out for recycling. We often see these drums used in metal recycling lines and car shredders, where they can process large amounts of mixed waste quickly and precisely.

- Mining: In the mining industry, magnetic drums help us extract iron-containing minerals such as iron and magnetite from ore. Conveyors and rotary screens in the mining industry work best with magnetic drums. By separating these materials early in the process, subsequent refining is simplified.

- Food Processing: We use magnetic drums in grain mills and bulk conveyors, where they quietly and effectively remove metal fragments, preventing metal contaminants (such as machine debris) from entering food.

- Wood and Plastics Industry: Magnetic drums are a must-have for wood chippers and plastic shredders, and wood and plastic processing equipment can easily be damaged by stray metal parts. We use magnetic drums to remove nails, screws and other metal fragments, ensuring smoother production.

- Construction and aggregate processing: Magnetic drums help us separate rebar, nails and other metals. They are essential in concrete recycling lines and crushing plants, ensuring that the processed material is metal-free and can be reused in new projects.

In these industries, magnetic drums have proven their value by increasing efficiency, reducing waste and protecting other equipment.

There are two main types of magnetic drum separators.

When it comes to magnetic drum separators, it’s key to understand the two main types: permanent magnetic drums and electromagnetic drums. Each type has its own advantages and is suitable for specific applications. If you are looking for custom or bulk magnetic drums, it is important to understand the difference between permanent magnetic drums and electromagnetic drums.

Permanent Magnetic Drums

Permanent magnetic drums use materials such as neodymium to create a magnetic core, which can provide a constant magnetic field without any external energy. This makes them very energy efficient. They are particularly useful in environments where consistent, reliable separation is required but electrical power is limited or unstable.

One of the outstanding advantages of permanent magnetic drums is their low maintenance cost. Once installed, they will continue to work without additional energy input. Since the magnetism does not require any electricity, there is less wear and tear. Durable and long life.

This makes them ideal for long-term continuous operation in industries such as recycling, mining and construction. You just install them and they will work day after day to help you remove ferrous contaminants from bulk materials.

Electromagnetic drums

Compared to permanent magnet drums, electromagnetic drums use electric current to generate magnetic fields, providing flexible and adjustable magnetic strength. Electromagnetic rollers are ideal for dynamic environments where material composition or process requirements often change. Operators can adjust the current to control the generation of different magnetic forces for different usage scenarios.

However, electromagnetic rollers require more energy to operate and require maintenance of electrical components. They are not suitable for use in environments with unstable power environments such as underground mines.

The choice between permanent magnetic drums and electromagnetic drums depends on the actual needs of your operation. If you are looking for a simple, energy-saving solution with minimal maintenance costs, then permanent magnetic drums may be more suitable. However, if your operation requires a more adaptable approach to handling different types of materials or requires a strong, controllable magnetic field, then electromagnetic drums are your best choice.

What feeding forms are suitable for permanent magnet rollers?

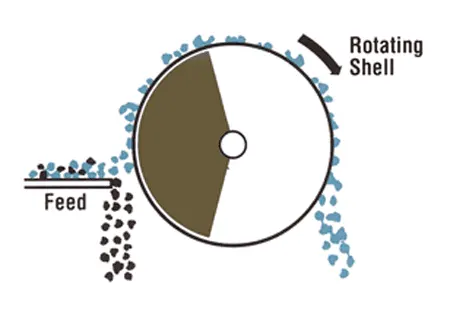

For permanent magnetic drum separation, choosing the right feeding form is crucial to ensure efficient material separation. Choosing the most cost-effective drum core type according to the feeding method plays a vital role. There are three common forms of horizontal upward, downward and top feeding for general magnetic drums.

Upward feeding:

Upward feeding is suitable for those magnetic drums with more than 90° fan-shaped magnetic cores. In this setting, metallic materials are attracted by the magnetic core and taken to the next sorting area by the selected magnetic drum, while non-metallic materials fall naturally from the feed port. This is very suitable for processing fine materials that require strong magnetic attraction to pull out ferrous particles, and is very suitable for applications with light to medium material flow.

Downward feeding:

Downward feeding is exactly the opposite of the rotation direction of upward feeding. When the metallic material is naturally moved by gravity, it will be attracted by the magnetic core and rotate a certain distance before entering the next sorting area. This method is particularly effective for large-volume, high-weight materials that need gravity to help them flow smoothly.

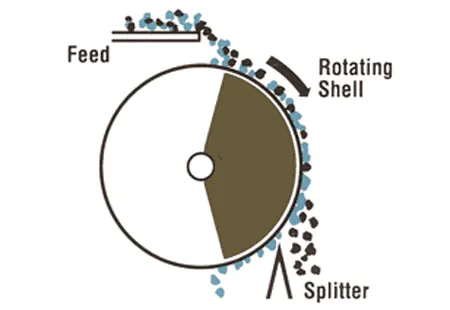

Top feeding:

Top feeding is another common form, and the material enters directly from the top of the magnetic drum. This approach ensures maximum exposure of the material to the magnetic field as it moves across the drum surface. It is often used for ferrous materials that are less magnetic.

Top feeding:

The first three feed methods can customize the magnetic sector angle according to actual needs and separation system connection settings, so as to help customers reduce costs. For applications that require greater flexibility, a fully solid drum is required. Unlike a sector drum, a solid drum can handle any feed pattern. Whether it is upward, downward or top feeding, a 360° solid drum can provide consistent separation performance. This type of drum is particularly popular in situations where a reversing belt conveyor needs to be replaced because it can adapt well to different feed directions. Therefore, they are an excellent choice for facilities with fluctuating material volumes or changing material types.

Selecting the right feed format for your drum is more than just a technical decision – it impacts the efficiency and productivity of your entire operation. Understanding how up, down and top feed systems interact with sector cores, or opting for a versatile solid drum, can result in smoother operation, better separations, and less downtime. If you’re unsure how to optimize your material separation process, feel free to explore custom solutions with Osencmag. We can customize magnetic strength, core type, and drum design to your exact requirements, ensuring your separation system operates at peak efficiency.

How to choose a permanent magnetic drum manufacturer?

Choosing the right permanent magnet drum manufacturer is important for any business that relies on separation technology. There are so many options on the market, and considering some essential aspects of a future partner can help you make an informed choice.

- Experience and expertise

Manufacturers with years of expertise know how to adapt to changing industrial needs and are able to provide tailored solutions based on a wealth of knowledge. A reliable partner not only manufactures magnetic drums, but also understands the industry and its challenges. - Customization capabilities

Due to the diversity of actual separation technologies, not all magnetic drums are the same. The magnetic strength, size, shell material, and even corrosion-resistant coating of the magnetic drum need to be customized to meet the needs of the specific application. The more customizable options a manufacturer offers, the more likely they are to meet the needs of the operation. - Manufacturing process and quality control

Transparency in the manufacturing process is the hallmark of a good manufacturer. It is important to ensure that the production process has a complete quality management system and is supported by in-house testing facilities. Manufacturers with high standards will implement strict quality control systems at every stage of production. - Customer support and after-sales service

Good manufacturers are more than just product manufacturers, they are long-term partners. A good partner will inevitably provide ongoing support, whether it is through installation guidance, troubleshooting, or maintenance tips. Responsive after-sales service is an important factor in ensuring smooth communication and long-term cooperation. - References and customer reviews

Always check references. Who have they worked with and what is their experience? Manufacturers with a good track record can serve as a judgment for future partnership prospects.

Usually, except for a few leading companies, few companies can cover all aspects. Either they only focus on the production of a certain process, or their customer service is not perfect, or their quality management system is not perfect, etc. We bring together factories and supplier resources with different expertise to help solve customers’ unique needs through our overall management. At the same time, we also regularly visit factories and conduct sampling tests to verify that they always provide reliable production.

What certifications or quality standards do your magnetic drums meet?

We are well aware of the importance of quality certifications to ensure the performance and life of our drums. Before we establish a partnership with any partner, we ask them about the certifications and industry standards they follow. That’s why we have established an eco-chain of raw materials and production plants with ISO, Rohs, CE and other certifications.

- ISO 9001 manufacturers follow a strict set of quality management principles to ensure consistent production quality, continuous improvement and customer satisfaction.

- RoHS (Restriction of Hazardous Substances) compliance ensures that the drum components are free of hazardous substances such as lead, mercury and cadmium.

- CE Mark: This certification means that the drums I deliver to our customers meet European safety, health and environmental protection standards.

- Material Testing Standards: High-performance drums are subject to rigorous material and magnetic strength tests. Depending on the needs of customers in different regions, we offer standards such as ASTM (American Society for Testing and Materials) or DIN (German Institute for Standardization).

Benefits of investing in spare magnetic rollers for your separation process include:

1 Wide-ranging standard magnetic rollers adaptable to various applications, cutting-edge magnetic simulation technology for optimized design and performance, and uninterrupted operations. Spare magnetic rollers ensure your material separation process remains uninterrupted, even during regular maintenance, repairs, or replacement of worn components. This helps maintain maximum efficiency and productivity.

2 Quick and easy replacement: Our magnetic rollers are designed for easy installation and replacement. Having a spare roller on hand allows you to quickly replace any worn or damaged components, minimizing downtime and ensuring a seamless continuation of the separation process.

3 Rigorous testing and quality control to guarantee durability and reliability. Extended equipment life: Regular rotation of spare magnetic rollers helps prolong the life of separation equipment by evenly distributing wear across multiple components. This not only minimizes the risk of unexpected breakdowns but also extends the overall lifespan of your magnetic separation system.

4 Customizable solutions tailored to your unique requirements. Improved operational efficiency: Maintaining a consistent and efficient material separation process, spare magnetic rollers help improve the overall operational efficiency of your facility. This can lead to increased throughput, reduced waste, and enhanced profitability.

Why us?

We pride ourselves on our commitment to innovation, quality, and customer satisfaction, ensuring you receive the most advanced, efficient solutions to meet your business needs. Our magnetic rollers offer standard and custom designs, guaranteeing you have the perfect solution for your unique material separation requirements. Like our primary products, our spare magnetic rollers are meticulously tested and fine-tuned for optimal performance, ensuring you receive a high-quality, reliable product you can trust.

Our pioneering simulation technology sets us apart in the competition. Our team of experts utilize this powerful tool to accurately predict the performance of our magnetic rollers across a wide range of applications. This allows us to fine-tune and optimize our designs to deliver the most precise and efficient magnetic separation solutions on the market.

Understanding that each business has unique requirements, we offer standard and custom magnetic rollers. Our diverse range of standard magnetic drums is professionally designed to cater to different industries such as recycling, mining, and waste management. If you require a tailored solution, our dedicated professionals are always ready to collaborate with you to design and manufacture custom magnetic rollers that completely meet your specific needs.

Our commitment to quality goes beyond product design. We ensure that every magnetic roller leaving our factory undergoes rigorous testing to guarantee optimal performance and durability. We also prioritize environmental sustainability, ensuring our manufacturing process is eco-friendly and adheres to the highest industry standards.

Investing in our magnetic rollers means adopting forward-thinking solutions to meet your material separation needs.

By leveraging our advanced simulation technology and offering customizable magnetic drums, we guarantee unmatched efficiency and precision in separating ferrous and non-ferrous materials.

Magnetic drums for separators that we have supplied in the past.

-

Magnetic Drum

Mining permanent magnet neodymium drums

-

Magnetic Drum

Wood crushing factory magnetic drum filter roller

-

Magnetic Drum

Large industrial wear-resistant rare earth magnetic drum

-

Magnetic Drum

Removable shell magnetic drum for recycling industry

-

Magnetic Drum

Construction metal aggregate magnetic drum separator

Our superior capabilities in manufacturing magnetic drums

Rich manufacturing experience

We have more than 20 years of experience in manufacturing magnetic products, and professional and reliable technology provides customized magnetic drum solutions for various industries and customers' unique operating requirements.

Customized flexibility

We provide comprehensive customization of magnetic drums, including size, magnetic properties, shell materials and coatings. Flexible manufacturing processes ensure that each magnetic drum meets the specific business needs of customers.

Quality control and certification

We follow strict quality control procedures and hold multiple certifications such as ISO 9001 and 19011 to ensure that each magnetic drum meets international standards for durability, performance and reliability.

Fast delivery and reliable supply chain

Our efficient production management system and perfect supply chain enable us to deliver magnetic drums on time, ensuring that your project is completed on time without delay.

Competitive pricing and long-term value

By integrating resources from all parties to customize a cost-effective manufacturing process, we offer competitive prices on the basis of ensuring the quality of magnetic drums. Providing excellent long-term value to our customers.

Dedicated Customer Support

Our responsive customer service team is always available to provide you with technical guidance on ordering, responsible after-sales support and maintenance advice to ensure that all your needs for magnetic drum concentrators are met promptly and professionally.

Other Magnetic Assemblies

Other Precision Magnetic Assemblies Products We Support

Magnetic Rotors

Magnetic Rotors

Designed for high efficiency and durability, magnetic rotors enhance the power and life of motors and generators.

FAQs about magnetic drum

Can magnetic drums be customized for specific applications?

Of course! We specialize in customizing drums to meet your exact application needs. Whether it’s a specific material, magnetic strength, or unique operating conditions, we’ll work closely with you to develop the perfect solution.

Can I request specific magnetic strengths and dimensions for my magnetic drum separator?

Yes, you can. We offer fully customized magnetic forces, drum sizes, and dimensions to meet your specific material separation requirements. Whether you require higher magnetic forces or a specific drum size, we can ensure the design fits your operational needs.

What is the lead time for ordering custom magnetic drum separators in bulk?

Lead times depend on your specifications and order size, but we typically deliver bulk custom drums within 4-6 weeks. We prioritize clear communication and efficient production to meet your deadlines. If you have an urgent need, please let us know and we’ll work to meet a tighter timeline.

What are the minimum order quantities for bulk purchases of magnetic drum separators?

Our minimum order quantity (MOQ) for bulk drum separators is very flexible and depends on the degree of customization required. For standard designs, MOQs can be as low as 10 units, while highly specialized orders can be customized to your specific needs.

Can I get a sample magnetic drum before placing a bulk order?

Yes, we provide drum samples for your evaluation before placing a volume order. Customized drums are also produced as prototypes before volume production to ensure the product meets customer expectations. Samples help build confidence and we are happy to provide samples to support your decision-making process.