Halbach Array Magnetic Assemblies

Halbach array is a magnet arrangement structure. It is one of the effective ways to achieve the maximum directional magnetic field using permanent magnets. It consists of multiple high-grade magnets placed on a plane in an alternating manner. Through a unique array method, the magnetic field of each magnet is directed in the target direction, where they can combine to produce incredibly strong magnetic field strength. As a well-known Halbach Array company in China, Osencmag has excellent experience in customized production and provides efficient and reliable Halbach array component manufacturing services to our customers.

Customizable Aspects of Halbach Array Assemblies

Custom shape

Customize Halbach's shape, including arc, line, cylinder, sphere and customized overall component shape.

Custom magnetic structure

Customize the configuration structure and magnetic array mode according to the shape. The number of discrete magnets in the structure directly affects the uniformity of the magnetic field.

Custom fixture

Customized fixture is used to encapsulate the magnets of Halbach array.

Custom magnetic properties

Customize magnetic grade performance according to actual intrinsic coercivity, magnetic energy product, operating temperature coefficient and other requirements.

Custom coating

Customize component coating to help protect magnet performance, anti-corrosion, waterproof and salt spray resistant.

Custom size

Customize the size of the target Halbach component, from small experiments to large industrial equipment.

Choose OSENCMAG to Help You

With two decades of expertise, we have the knowledge and manufacturing capabilities to assemble Halbach array assemblies precisely and efficiently, ensuring optimal performance and customer satisfaction. Ensure optimal performance and efficiency in a variety of advanced magnetic system applications.

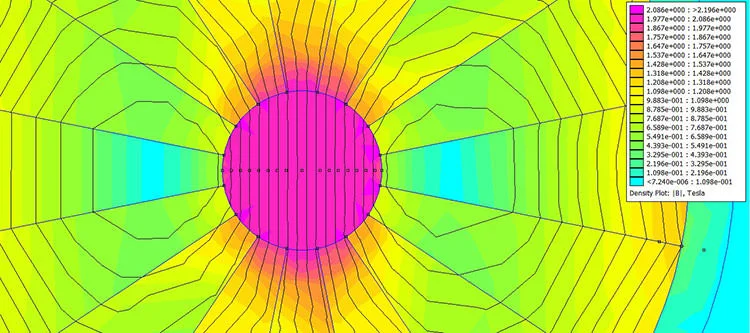

What Is Halbach Array?

Halbach array is a special permanent magnet magnetic assemblies, which makes the magnetic field on one side of the array stronger, while the magnetic field on the other side is offset to near zero. This is very different from the magnetic field around a single magnet. The Halbach array is designed to achieve the maximum magnetic field. With the same volume and magnet material, the magnetic field strength on the strong side of the Halbach array magnet group is about 1.4 times that of a traditional single magnet, especially when the magnet thickness is 4-16mm.

This special permanent magnet arrangement principle was invented by James (Jim) M. Winey at Magnepan in 1970. However, it was designed and promoted by the famous physicist Klaus Halbach Halbach in the 1980s, mainly for improving the performance of particle accelerators.

When manufacturing Halbach arrays, high-performance permanent magnets are usually used as the main components, usually including: neodymium magnets, samarium cobalt and ferrite.

In general, neodymium magnets are the most commonly used choice. To maintain a good magnetic field in a particularly high temperature working environment (>230°C), samarium cobalt magnets are the best choice. Ferrites are only suitable for customers who pursue low cost and have low performance requirements. The prices of the same type of magnet materials are also differentiated by material models. You can contact us and our professional engineers will recommend the most suitable Halbach permanent magnet material specifications based on magnetic force, operating temperature, corrosion resistance, price and the specific application environment of your project.

Halbach array magnetic components also need to be matched with metal materials as the structural skeleton fixture of the entire component, usually including: aluminum, brass, stainless steel, steel. Typically, small Halbach arrays use aluminum frames and brass. Large Halbach component exoskeletons use steel.

Characteristics of Halbach array.

It is well known that the most obvious advantage of Halbach array dipoles is the very strong magnetic field they produce compared to other arrays with the same number of magnet alloys. This super magnetic array structure has the following advantages:

- Very strong magnetic force: The Halbach array configuration amplifies the magnetic field on one side of the array, resulting in a much stronger magnetic field than is typically produced by a conventional magnet arrangement. This concentrated magnetic field is very useful for applications that require high magnetic field strength in a specific direction. Because Halbach magnets have a segmented magnetization effect, their permanent magnet efficiency is high, generally above 0.9, which improves the utilization of permanent magnets.

- Self-shielding characteristics: Due to its unique design, the Halbach array produces a strong magnetic field on one side, while the magnetic field on the other side is almost canceled. This self-shielding characteristic reduces magnetic interference with surrounding components and the environment, thereby improving the overall efficiency of the magnetic system.

- Alternating magnetization direction: The magnets in the Halbach array are arranged in a pattern of alternating magnetization directions. This systematic change of direction ensures that the magnetic field is constructively combined on the desired side, further enhancing the magnetic field strength and uniformity.

- Strong magnetic field on one side: The design of the Halbach array ensures that the magnetic field is concentrated on only one side, providing a strong directional magnetic field. This one-sided property is ideal for applications where exposure to magnetic fields on one side must be minimized, such as magnetic shielding and certain types of magnetic sensors.

- Ideal sinusoidal distribution of magnetic field in space: The magnetic field generated by a carefully constructed Halbach array approximates an ideal sinusoidal distribution in space. This smooth, regular magnetic field distribution is particularly advantageous in applications that require a precise and uniform magnetic field, such as magnetic resonance imaging (MRI) and other advanced imaging technologies.

The main disadvantage of the Halbach array geometry is that it is difficult to assemble. All magnets in the Halbach array repel each other, which poses a considerable challenge to the manufacture of the Halbach array:

- Necessity of magnetization assembly: Building a Halbach array requires precise alignment and magnetization of the individual magnets. The magnets must be carefully positioned and assembled to obtain the desired magnetic map, a process that can be very complex and time-consuming.

- Opposing magnetic forces during assembly: Strong magnetic forces within the array can make assembly difficult. Magnets tend to attract or repel each other with great force, complicating the process of aligning and fixing them to the correct orientation without damage or misalignment.

- Ensure component integrity: It is critical to maintain the structural integrity of the Halbach array throughout its service life. The array must be strong enough to withstand mechanical stress and thermal changes without losing its precise magnetic configuration. This requires careful design and high-quality manufacturing practices to ensure long-term stability and performance.

Another disadvantage that cannot be ignored is that the magnets are arranged in a direct or quasi-direct repulsion manner, which means that the magnets in the array structure will be affected by the adjacent magnets and produce demagnetization. For permanent magnets with high coercivity, this may not be a problem unless high temperatures are required in the application – as the operating temperature increases, the magnets are more susceptible to demagnetization, and the demagnetization of adjacent magnets will be aggravated. This is why we insist on providing customers with neodymium magnets (necessarily recommending samarium cobalt magnets) solutions, whose high coercivity (Hc and HcJ), high remanence (Br) capabilities and temperature resistance can better avoid demagnetization.

Although there is a certain complexity in manufacturing and assembling Halbach arrays. However, due to the significant advantages of Halbach arrays in enhancing and guiding magnetic fields, they are of immeasurable value in a variety of high-performance applications. The cost of manufacturing difficulty cannot offset these advantages.

How Does a Halbach Array Assemblies Work?

The Halbach array is a clever configuration of permanent magnets that creates a unique magnetic field distribution by arranging them in a specific pattern. This makes more efficient use of the available magnetic flux, resulting in a stronger magnetic field than other configurations. Here’s how it works:

- Magnetic field enhancement: The rotating magnetic orientation causes the magnetic fields of the individual magnets to constructively combine on one side of the array. This results in a stronger, more uniform magnetic field on that side.

- Magnetic field cancellation: On the other side, the magnetic fields cancel each other out, resulting in a significantly weaker field on the other side.

Imagine you have a row of bar magnets. If all the magnets were aligned with their north poles facing the same direction, the magnetic field would be relatively uniform on both sides of the row. However, in a Halbach array, the staggered orientation of the magnets causes the magnetic field to be concentrated on one side.

Comparing Halbach Arrays to Conventional Arrangements

To better understand the uniqueness of Halbach arrays, let’s compare them to two more common magnetic arrangements:

- Simple Linear Arrangement:In a simple linear arrangement, all magnets are aligned with their north poles facing the same direction. This creates a uniform magnetic field around the magnets, with no significant enhancement or cancellation on either side.

- Alternating Poles Arrangement:In an alternating poles arrangement, magnets are placed with alternating north and south poles. This creates a fluctuating magnetic field with regions of strong and weak fields along the length of the array.

In contrast, the Halbach array’s strategic orientation of magnets ensures a concentrated magnetic field on one side and a negligible field on the other. This property is highly advantageous in applications where a focused magnetic field is required.

What Is A Halbach Array Used for?

Since the 1990s, Halbach components have attracted widespread attention in the industrial and academic fields due to their unique advantages. More and more professionals have conducted special research on them, making their application areas more and more extensive.

Halbach array assemblies are used in a wide range of applications, from refrigerator magnets to industrial applications such as particle accelerators, brushless motors, magnetic coupling, magnetic levitation, synchrotron radiation, single degree of freedom actuators, synchrotron light sources, electromechanical batteries, flywheel energy storage, magnetic bearings, high-efficiency power equipment, etc.

- Single Degree of Freedom (DOF) Actuators:

Benefit from the enhanced performance and efficiency provided by Halbach arrays to help single degree of freedom (DOF) actuators generate strong localized magnetic fields. These actuators are often used in precision engineering and robotics. The concentrated magnetic field improves force generation and control, resulting in more precise and responsive actuator systems. - Magnetic Levitation (Maglev):

Halbach arrays are essential in magnetic levitation systems, such as maglev trains. These arrays use the repulsive force of the magnetic field to generate a strong directional magnetic field to provide the necessary lift to lift the train above the track, thereby reducing friction and enabling higher speeds and a smoother ride. - Electromechanical Batteries:

Halbach arrays can be used to make electromechanical batteries for renewable energy systems and backup power, where mechanical energy is stored and converted into electrical energy. The unique magnetic field properties of the Halbach array can effectively increase the efficiency of energy conversion and storage. - Synchrotron Light Sources:

Halbach arrays generate highly focused, strong magnetic fields that are used to focus and direct electron beams within synchrotrons. They play a key role in synchrotron light sources, generating precise magnetic fields that enhance the quality and intensity of the synchrotron light. These devices produce intense beams of light used for scientific research in fields such as biology, chemistry and materials science. - Particle Accelerators:

Halbach arrays were originally developed for particle accelerators to focus and guide charged particles. The uniform magnetic fields produced by these arrays enhance the stability and control of particle accelerators used in scientific research and medical applications, thereby improving precision and efficiency. - Synchrotron Radiation:

Halbach arrays are also used for imaging and spectroscopy in a variety of scientific and industrial applications. Halbach arrays are able to generate the strong local magnetic field needed to accelerate particles and emit radiation as the particles pass through the magnetic field. This magnetic field can help produce high-intensity and high-precision synchrotron radiation. - Flywheel Energy Storage:

In flywheel energy storage systems, Halbach arrays are used to improve performance and efficiency. These systems store kinetic energy in a spinning flywheel and convert it back into electrical energy when needed. Halbach arrays enhance the magnetic bearings that support the flywheel, reducing friction and increasing the efficiency of energy storage and recovery. - Magnetic Bearings:

In magnetic bearings, Halbach arrays create a stable, non-contact bearing surface. This reduces wear, extends bearing life, and allows operation in extreme environments where conventional bearings may fail. The strong, stable magnetic field produced by the Halbach array ensures smooth, frictionless operation, extending the life stability and efficiency of the bearing. - Motors:

Halbach array motors are known for their high efficiency and performance. The unique magnetic configuration of the Halbach array enhances the motor’s torque and reduces energy losses because the parallel magnetic field overlaps the radial magnetic field after the Halbach magnetic ring is disassembled, making the magnetic field on the other side much stronger. These motors benefit from a focused magnetic field, which increases their overall efficiency and power output. Halbach array motors have become ideal for a variety of applications ranging from electric vehicles to industrial machinery.

Halbach arrays have revolutionized various fields by providing efficient and powerful magnetic fields for specific applications. From improving the performance of single-degree-of-freedom actuators and maglev trains to improving the efficiency of electromechanical batteries and flywheel energy storage systems, the multiple applications of Halbach arrays have demonstrated their importance in modern technology. In addition to the above common application scenarios, Halbach magnetic components are also used in magnetic refrigeration applications, oil exploration calibration equipment, medical MRI equipment, and some fixed devices. Understanding the various uses of Halbach arrays can help drive innovation and development in multiple industries.

What Types of Halbach Array Structures Are There?

As modern technology continues to study how to maximize the magnetic flux of the Halbach array and how to use the Halbach array to meet different application requirements. After a lot of experimental research, a variety of Halbach array kits with different structures have emerged in the industry. From traditional to improved, from single pole to double pole, unequal pole to multi-pole and other magnet configurations, each configuration has unique magnetic field characteristics and applications. But no matter how the number changes, no matter whether the structure is square, straight, circular or arc-shaped. Based on the Halbach array principle, the final magnetic strength will be concentrated on one surface.

The following are several types of Halbach array structures that we often provide to customers:

- Linear Halbach array

- Cylinder/ring Halbach array

- Arc segmented Halbach array

- Spherical Shape Halbach Array

Linear Halbach array

The linear (Planar) Halbach array is the simplest form, consisting of a series of permanent magnets arranged in a linear sequence. The direction of each magnet is rotated in a specific pattern to produce the desired magnetic field effect. This array magnet can be regarded as a combination of radial array and tangential array. It is composed of rectangular permanent magnets mounted on a ferromagnetic backplane. These permanent magnets have different magnetic directions, which are used to enhance the magnetic field on one side and almost cancel the magnetic field on the other side, thereby producing a uniform and strong half-sine magnetic field. For example, a typical sequence may have the north pole of consecutive magnets facing up, right, down and left, thereby producing a strong and uniform magnetic field on one side.

Linear Halbach arrays are currently mainly used in linear motors, and typical use cases are maglev trains and maglev bearings.

The levitation principle of maglev trains is that the moving magnets interact with the magnetic field generated by the induced current in the conductor to generate a levitation force, accompanied by magnetic resistance. Improving the buoyancy-to-drag ratio is the key to improving the performance of the suspension system, which requires the on-board magnets to be light in weight, strong in magnetic field, uniform in magnetic field, and highly reliable. The Halbach array is installed horizontally in the center of the car body, and generates propulsion in the center of the track by winding. The magnetic field is maximized with a small number of magnets, and the magnetic field on the other side is smaller, which can prevent passengers from being affected by the strong magnetic field.

Magnetic bearings use magnetic force to suspend the rotor in the air, so that there is no mechanical contact between the rotor and the stator. The principle is that the magnetic induction line is perpendicular to the magnetic levitation line, and the shaft core is parallel to the magnetic levitation line, so the weight of the rotor is fixed on the running track, and the shaft core is almost unloaded to support the direction of the anti-magnetic levitation line, so that the entire rotor is suspended in the air on a fixed running track. Compared with traditional ball bearings, sliding bearings and oil film bearings, magnetic bearings have no mechanical contact, and the rotor can reach a very high operating speed. It has the advantages of low mechanical wear, low energy consumption, low noise, long life, no lubrication, and no oil pollution.

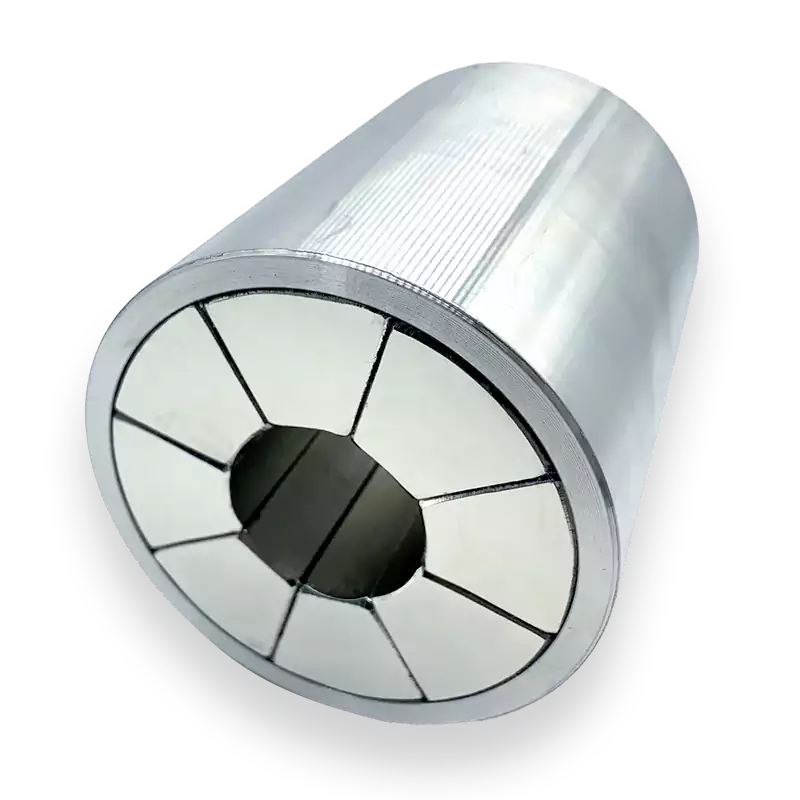

Ring/Cylinder Halbach Array

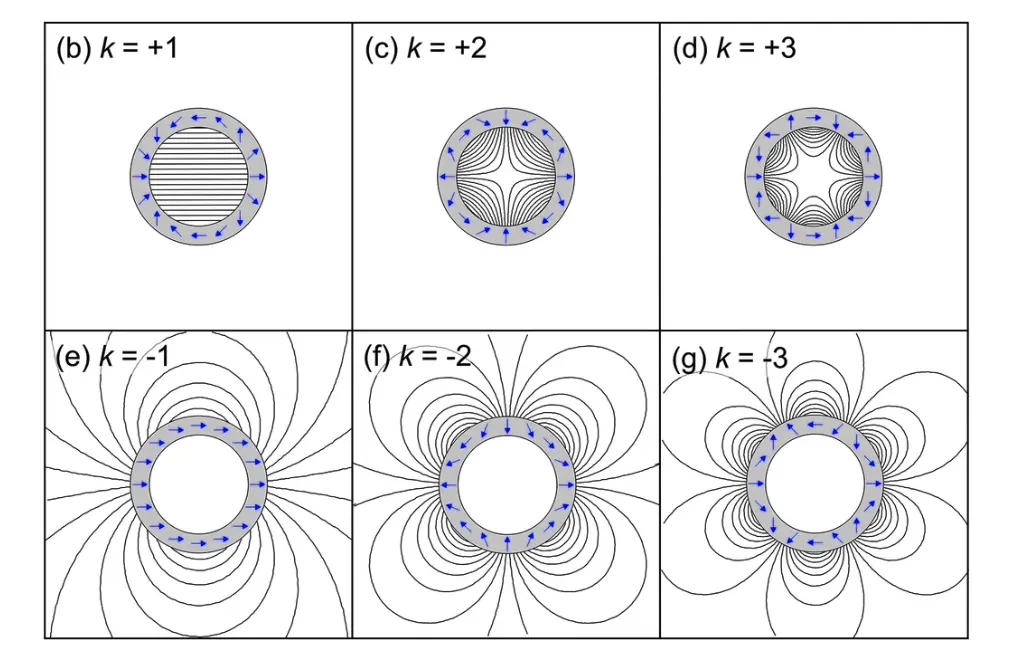

Cylindrical or ring Halbach arrays consist of magnets arranged in a cylindrical shape. Ring Halbach arrays can be thought of as linear Halbach arrays placed end to end to form a ring. This type is often used to produce a strong, uniform magnetic field within the cylinder while minimizing external magnetic fields. In a cylindrical Halbach array kit, the magnets are oriented so that the magnetic field vector rotates around the circumference of the cylinder.

Cylindrical Halbach arrays are built from dipole to quadrupole, sextupole, hexapole, octupole and other magnet configurations. It is important to note that the greater the number of discrete magnets, the greater the number of magnetic vector angles, and the more uniform the magnetic field on the inner diameter of the Halbach assembly.

Because of this magnetic array structure, a strong radial magnetic field is generated within the cylinder, while the external magnetic field is significantly reduced. The result is a highly efficient and concentrated magnetic field that is ideal for rotating machinery. For example, in permanent magnet motors, permanent magnet motors with Halbach array structures have more sinusoidal air gap magnetic fields than traditional permanent magnet motors. With the same amount of permanent magnet material, the air gap magnetic density of Halbach permanent magnet motors is larger and the iron loss is smaller. In addition, Halbach ring arrays are also widely used in permanent magnet bearings (magnetic couplers), magnetic refrigeration equipment, and magnetic resonance equipment. They are also used in magnetic resonance imaging (MRI) to create uniform magnetic fields for medical imaging purposes.

Arc Halbach

Arc Halbach arrays consist of magnets arranged in an arc. This configuration is often used to conform to curved surfaces or to generate radial magnetic fields. In an arc Halbach array, the orientation of the magnets follows the curvature of the arc. This arrangement amplifies the magnetic field inside the arc while reducing the magnetic field outside. The result is a strong concentrated magnetic field along the inner surface of the arc, which is ideal for applications that require a radial magnetic field. It is also possible to reverse the amplification of the arc and reduce the magnetic field outside the arc. The structural configuration can be changed according to specific needs.

Arc Halbach magnets are one of the most widely used magnetic components. In the industrial field, they are often used in motors (to improve the performance of brushless DC motors) and magnetic couplers (to provide effective torque transfer between rotating shafts). Science DIY enthusiasts like to use arc Halbach magnet components on magnetic crawling robots.

Spherical Halbach Arrays

A spherical Halbach array is a more complex structure where the magnets are arranged in a spherical shape. In a spherical Halbach array, the magnets are oriented so that a strong, uniform magnetic field is generated within the sphere while minimizing the external magnetic field. This configuration is very complex and requires precise alignment of the magnets. This configuration is less common, but the spherical shape allows for three-dimensional magnetic field concentration. It is very useful in advanced research applications because it provides unique magnetic field properties. With professional and reliable expertise and factory resources, Osencmag has provided personalized and efficient spherical Halbach array assemblies to many well-known research institutions and universities.

Special Halbach Array

Spherical Halbach arrays are custom configurations designed for specific applications. Involving complex geometries customized for unique magnetic field requirements, multiple different grades of magnets can be combined when necessary. Two different grades of magnets can be used in this structure to achieve specific functions, such as combining N52 and N48SH in one Halbach array assembly.

The principle of spherical Halbach arrays is the same as other types: orienting magnets in a specific pattern to enhance the magnetic field on one side and weaken the field on the other side. The specific arrangement depends on the application and requires detailed magnetic field analysis and precise manufacturing techniques to achieve the desired effect.

How To Make A Halbach Array?

Through the above explanation, I believe you have a deep understanding of Halbach arrays. Are you interested in the manufacturing process of Halbach array components? Building Halbach arrays requires precise engineering design and careful manufacturing technology to ensure optimal performance. Below, we will tell you about the industrial process of manufacturing Halbach array components for customers.

Materials and preparation

- Selection of permanent magnets:

The main material for building Halbach arrays is high-quality neodymium (NdFeB) magnets. These magnets are selected for their strong magnetic properties and durability. Neodymium magnets are usually produced through a sintering process, which includes a series of steps such as powder preparation, pressing, sintering, and magnetization. The detailed neodymium magnet manufacturing process is explained in detail in our technical guide blog. - Cutting and forming:

After the sintered magnets are prepared, they are cut and formed into the required size. This step is crucial because accurate size and shape are essential to creating an effective Halbach array. Advanced cutting technologies such as wire cutting (EDM) and laser cutting ensure high precision and minimal material waste. We also use CNC processing when necessary.

Assembly Process

- Orientation and Alignment:

The unique magnetic properties of the Halbach array are achieved by arranging the magnets in a specific pattern. The orientation of the north and south poles of each magnet must be carefully aligned to enhance the magnetic field on one side. The most requested Halbach array configurations we receive include linear, cylindrical, and arc segment arrays. - Bonding and Encapsulation:

Due to the strong magnetic repulsion of the Halbach magnetic assembly, it is difficult to form the target arrangement. The magnets are bonded together using a high-strength adhesive. Additionally, because the Halbach structure is so complex, it requires specialized skills and custom jigs to assemble. This bonding process includes:

Surface Preparation: Cleaning and treating the surface of the magnets to ensure a strong bond.

Adhesive Application: Applying a specialized adhesive to the contact surface.

Alignment: The magnets are precisely aligned and clamped in place with a custom fixture until the adhesive cures.

In some cases, the bonded arrays are encapsulated in a specific protective metal material (aluminum, brass, stainless steel, steel, etc.) to increase durability and resistance to environmental factors such as moisture and corrosion. The encapsulation process may involve the application of epoxy or other protective coatings. - Quality Control and Testing:

Quality control is a critical step in the manufacturing process, and we implement strict inspection standards to ensure that Halbach arrays meet the performance standards required by customers. This includes:

Dimensional inspection: Verify the dimensions and tolerances of the assembled array.

Magnetic Field Testing: Using specialized scanning or analysis equipment to measure magnetic field strength and distribution to ensure the array is operating as expected.

Durability testing: Environmental and mechanical stress tests are performed on the array to verify its robustness.

It is worth mentioning that for large-volume Halbach magnetic Assemblies orders with relatively small and simple array structures, we will adopt another manufacturing method: first, customize the specially designed magnetization fixture and magnetization process in advance. Then use mold filling or compression molding methods to manufacture the complete magnet, and finally magnetize it in a specially designed fixture. This method is more efficient in mass production and can help customers save costs when placing bulk orders. You don’t have to worry about clamps/fixtures, our factory will take care of the entire process from design to manufacturing.

Building a Halbach array involves a meticulous process of selecting high-quality neodymium magnets, precise cutting and forming, precise alignment and bonding, and strict quality control. At Osencmag, our commitment to expertise and precision ensures that our Halbach arrays provide excellent performance and reliability. Whether it is used for industrial applications, advanced research or cutting-edge technology, our Halbach arrays meet the highest standards of quality and efficiency.

Things you must know when customizing Halbach arrays.

Manufacturing Halbach arrays requires not only professional technology and precision equipment, but also a rigorous attitude. Nevertheless, due to the special characteristics of Halbach arrays, your expectations for target Halbach array assemblies must take into account the following two points.

Homogeneity

If you need a consistently uniform setup, opting for a ring Halbach array might not be the best choice. Many scientists often request a Halbach array with a homogeneity level of 300ppm, which seems plausible in theory but proves challenging in actual production. This difficulty arises due to the impact of magnetic declination and limitations in magnetic assembly capabilities. In such cases, we strongly advise considering a yoke design, which is commonly employed to generate a consistent magnetic field for NMR (nuclear magnetic resonance) instruments.

The gap between simulation and reality

For the simulation of small-sized Halbach array, the error between the results and the actual results is about +5% and -10%. But for large sizes, the error is very likely to reach -25% or -30%.

According to our historical manufacturing statistics, it is difficult to guarantee exactly the same magnetic field even if Halbach arrays are manufactured at the same time. This is something that no manufacturer can avoid at present. The only thing they can do is to adjust the materials and processes to get as close to the simulation data as possible. This is also one of the important reasons why proofing is needed before mass production.

Halbach array magnetic assemblies we have provided in the past.

-

Halbach Arrays

N52 Neodymium Magnet Halbach Array Rotor Assembly

-

Halbach Arrays

Tile Arc Halbach Array Permanent Magnet Neodymium Magnet

-

Halbach Arrays

Ring Permanent Magnet Halbach Array Motor Assembly

Our Capabilities in Halbach Array Magnetic Assemblies

At Osencmag, we pride ourselves on our comprehensive capabilities in designing, manufacturing, and delivering high-quality Halbach array magnetic assemblies. Here’s a detailed look at our expertise:

Production Capabilities

- High-Volume Manufacturing: Equipped with the equipment to handle large-scale production with consistent quality.

- Custom Manufacturing: Customized production processes to meet specific customer requirements.

Professional Design Assistance

- Expert Consultation: Our team of experienced engineers provides professional design assistance to optimize Halbach array configurations.

- CAD and Simulation Services: Utilizing advanced CAD software and magnetic simulation tools to ensure precise design specifications.

Precision Cutting and Shaping

- Advanced Machining: State-of-the-art machining facilities for accurate cutting and shaping of magnetic components.

- Complex Geometries: Capable of producing intricate shapes and structures to meet diverse application needs.

Quality Assurance Measures

- Strict Quality Control: Rigorous quality control processes throughout the production cycle.

- ISO Certification: Adherence to international quality standards to ensure high reliability and consistency.

Accurate Alignment and Bonding

- Precision Alignment: Specialized equipment and techniques for precise alignment of magnetic elements.

- Strong Bonding: High-strength adhesives and bonding methods to ensure durability and stability of assemblies.

Multi-Discrete Magnet Configurations

- Versatile Configurations: Expertise in designing and producing multi-discrete magnet configurations to achieve desired magnetic field effects.

- Custom Assemblies: Ability to create custom assemblies that meet unique application requirements.

Combination of Different Magnetic Grades

- Diverse Material Options: Access to a wide range of magnetic materials and grades to suit various performance needs.

- Optimized Performance: Combining different magnetic grades to enhance the overall performance of the assembly.

Comprehensive Testing

- Magnetic Field Testing: Advanced testing facilities for precise measurement and analysis of magnetic fields.

- Mechanical Testing: Comprehensive mechanical testing to verify the structural integrity and durability of assemblies.

Other Magnetic Assemblies

Other Precision Magnetic Assemblies Products We Support

Magnetic Rotors

Magnetic Rotors

Designed for high efficiency and durability, magnetic rotors enhance the power and life of motors and generators.

FAQs about Halbach Array Assemblies

What customization options are available for Halbach arrays?

At Osencmag, we offer extensive customization options for Halbach arrays, including the choice of magnetic materials (such as Neodymium or Samarium Cobalt), array configurations, magnetic field strength, operational temperature range, and precise dimensional tolerances. We work closely with clients to design arrays that meet specific performance requirements and are tailored to their application needs.

What is the typical lead time for producing a custom Halbach array?

The lead time for custom Halbach arrays can vary depending on the complexity and scale of the project. Generally, our lead time ranges from 4 to 8 weeks from the finalization of design specifications to delivery. We prioritize clear communication and efficiency in our production process to ensure timely delivery.

How does Osencmag ensure the quality and consistency of Halbach arrays?

Quality is at the core of our manufacturing process. We implement strict quality control measures at every stage of production, including material selection, precision assembly, and final testing. Each Halbach array is inspected for magnetic field uniformity, dimensional accuracy, and overall performance to meet the highest industry standards.

Can you provide examples of industries or applications where your Halbach arrays are used?

Our Halbach arrays are utilized in a wide range of industries, including medical devices, renewable energy, automotive, robotics, and scientific research. They are often used in applications requiring highly focused magnetic fields, such as MRI machines, magnetic levitation systems, and electric motor assemblies.

What certifications or compliance standards does Osencmag adhere to for Halbach arrays?

Osencmag is committed to maintaining the highest standards of quality and safety. Our Halbach arrays are manufactured in compliance with international standards such as ISO 9001 for quality management and RoHS for environmental safety. We can also meet specific regulatory requirements based on the customer’s region or industry.

How does Osencmag support clients in the design and development of custom Halbach arrays?

Our engineering team collaborates closely with clients from the initial concept through to final production. We provide expert guidance on the design of Halbach arrays, including magnetic field simulations, material selection, and optimization for performance. Our goal is to ensure that the final product meets all functional and technical specifications.

What is the minimum order quantity (MOQ) for custom Halbach arrays?

The minimum order quantity (MOQ) for custom Halbach arrays depends on the complexity of the design and the specific requirements of the project. We strive to be flexible in meeting our clients’ needs, and our MOQ can be discussed and adjusted based on the scope of the order.

How does Osencmag handle confidentiality and intellectual property (IP) for custom projects?

We understand the importance of confidentiality and IP protection in custom projects. Osencmag is committed to safeguarding our clients’ proprietary information. We are willing to sign non-disclosure agreements (NDAs) and adhere to strict protocols to ensure that all design and production details remain confidential.