Ever wondered how does a magnetic drum separator work to pull metal contaminants from your product stream like magic? These industrial workhorses save manufacturers millions of dollars every year by protecting equipment and ensuring product purity.

Here’s the thing:

Understanding magnetic separation isn’t just for engineers anymore. Whether you’re in mining, food processing, or recycling, these machines are probably already protecting your bottom line. In this post, as a professional magnetic drum manufacturer, I will share everything about the magnetic drum separator.

Table of Contents

What Is a Magnetic Drum Separator?

Let’s start with the basics.

A magnetic drum separator is basically a self-cleaning metal detector on steroids. It continuously removes ferrous materials from dry, free-flowing bulk materials without any manual intervention.

Think of it like this:

Imagine a rotating drum with a powerful magnet inside. As your material flows over the drum, any iron or steel gets stuck to the surface while everything else falls away. The drum keeps spinning, carrying the metal to a separate collection area.

Pretty smart, right?

The Core Components That Make It Work

Here’s what makes these machines tick:

1. The Rotating Drum Shell

The outer drum is made from non-magnetic stainless steel. This is crucial because if the drum itself was magnetic, it wouldn’t work properly.

Most drums range from 12 to 24 inches in diameter. Bigger operations might use drums up to 60 inches wide.

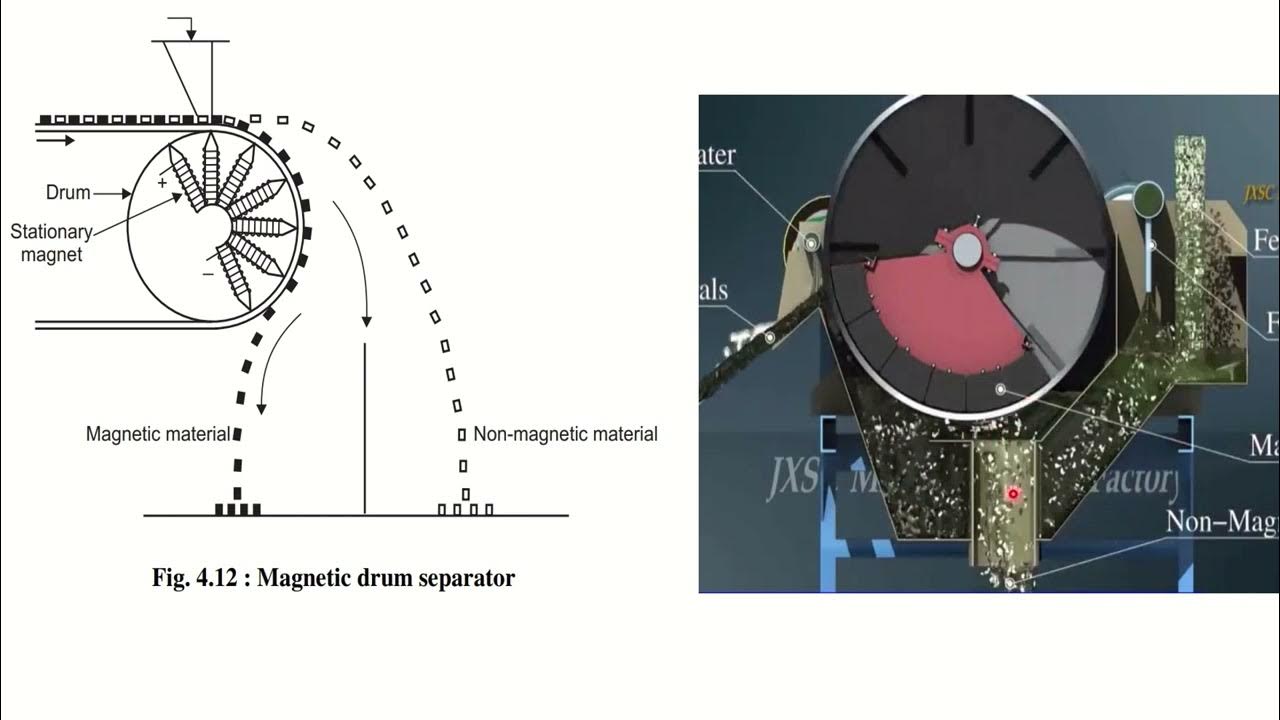

2. The Stationary Magnetic Core

This is where the magic happens.

Inside the rotating shell sits a fixed magnetic assembly. It typically covers 120° to 180° of the drum’s circumference. These magnets can be:

- Ceramic magnets (good for basic applications)

- Rare earth magnets (when you need serious pulling power)

The magnets don’t move. Only the outer shell rotates around them.

3. Feed System

You can’t just dump material onto the drum and hope for the best.

Most setups use:

- Vibratory feeders for controlled flow

- Conveyor belts for continuous operations

- Gravity chutes for simple applications

4. Discharge Chutes

These physical barriers separate the clean product from the captured metal. Without proper chutes, you’d just mix everything back together.

How Does a Magnetic Drum Separator Work

Now for the good stuff.

Here’s exactly how these machines separate metal from your product:

Step 1: Material Introduction

Your mixed material flows onto the drum surface through the feed system. The key here? Uniform distribution.

If material bunches up, separation efficiency drops like a rock.

Step 2: Magnetic Capture

As material passes over the drum, the magnetic field does its thing.

Ferrous materials (iron, steel, magnetic stainless) get instantly attracted and stick to the drum surface. The magnetic force is strongest right at the drum surface and weakens as you move away.

Non-magnetic materials? They couldn’t care less about the magnet. They follow gravity and fall into the clean product chute.

Step 3: Transport Phase

Here’s where it gets clever.

The drum shell rotates (usually 20-40 RPM), carrying the captured metal along for the ride. The metal stays stuck because it’s still within the magnetic field.

Step 4: The Release

Remember how the magnet only covers part of the drum?

As the drum rotates, it carries the metal past the edge of the magnetic field. Once the metal moves beyond the magnet’s influence, gravity takes over. The metal drops into a separate collection chute.

Step 5: Continuous Operation

The best part?

This process repeats endlessly. No stopping. No manual cleaning. The drum just keeps spinning, separating metal 24/7.

Real-World Applications That Matter

Let me show you where these separators really shine:

Mining Operations

In iron ore processing, magnetic drums recover valuable magnetite from waste rock. Some operations report recovery rates above 95%.

Food Processing

Ever found a metal fragment in your cereal? Neither have I, thanks to magnetic separation.

Food plants use these drums to remove:

- Broken machinery parts

- Nails from wooden pallets

- Metal shavings from conveyors

Recycling Facilities

Recyclers use magnetic drums to:

- Pull steel from shredded cars

- Separate ferrous metals from municipal waste

- Clean recycled glass of metal contaminants

Chemical Processing

Chemical plants protect their equipment by removing:

- Valve fragments

- Pipe scale

- Metal catalyst particles

The Science Behind the Separation

Time to get a bit technical (but I’ll keep it simple).

The separation depends on magnetic susceptibility – basically how much a material loves magnets.

Materials fall into three categories:

- Ferromagnetic (strongly attracted)

- Iron, steel, nickel

- Some stainless steels

- Paramagnetic (weakly attracted)

- Aluminum (barely)

- Platinum

- Some minerals

- Diamagnetic (slightly repelled)

- Copper, gold, silver

- Most plastics

- Organic materials

Magnetic drum separators work best with ferromagnetic materials. The stronger the magnetic response, the better the separation.

Key Factors That Affect Performance

Not all separations are created equal.

Here’s what impacts how well your drum separator works:

1. Belt Speed

Too fast? Metal doesn’t have time to stick.

Too slow? You’re wasting production capacity.

The sweet spot usually sits between 100-300 feet per minute.

2. Material Depth

Thicker material beds mean weaker magnetic fields at the top. Most operations keep depth under 2 inches for best results.

3. Particle Size

Smaller particles need stronger magnets. A nail is easy to catch. Iron dust? That’s trickier.

4. Moisture Content

Wet materials can cause clumping, reducing separation efficiency. Most drums work best with moisture under 5%.

5. Temperature

High temps can demagnetize permanent magnets. Most ceramic magnets lose strength above 180°F. Rare earth magnets can handle up to 350°F.

Choosing the Right Magnetic Drum Separator

Here’s my framework for selecting the perfect drum:

Step 1: Define Your Goals

What are you trying to achieve?

- Protect downstream equipment?

- Recover valuable metals?

- Meet purity specifications?

Step 2: Analyze Your Material

Consider:

- Particle size range

- Flow rate (tons per hour)

- Type of ferrous contaminants

- Material characteristics (dusty, sticky, abrasive?)

Step 3: Calculate Required Strength

This gets technical, but here’s the simplified version:

Light contamination (occasional nuts, bolts): Standard ceramic magnets

Heavy contamination (continuous metal): Rare earth magnets

Fine particles (metal dust, shavings): Definitely rare earth

Step 4: Size Your System

Drum width should be at least 6 inches wider than your material stream. This prevents spillage around the edges.

Installation Best Practices

I’ve seen great separators fail because of poor installation.

Here’s how to do it right:

Location Matters

Install your drum where:

- Material flow is already controlled

- There’s easy access for maintenance

- Discharged metal won’t contaminate clean product

Height Considerations

The drum should sit 6-12 inches above your conveyor belt. Too high reduces magnetic attraction. Too low causes mechanical interference.

Support Structure

These drums can weigh over 1,000 pounds. Your support frame needs to handle:

- Static weight

- Rotational forces

- Material impact loads

Electrical Requirements

Most drums need:

- 3-phase power for the motor

- Variable speed drive (optional but recommended)

- Safety lockout capabilities

Maintenance That Prevents Problems

The beauty of magnetic drums? They’re incredibly low maintenance.

But “low” doesn’t mean “no.”

Daily Checks

- Visual inspection for buildup

- Listen for unusual noises

- Check discharge chutes for blockages

Weekly Tasks

- Clean the drum surface

- Inspect belt/chain tension

- Verify rotation speed

Monthly Maintenance

- Lubricate bearings

- Check mounting bolts

- Test magnetic strength

Annual Overhaul

- Replace worn shells

- Rebuild drive components

- Professional magnetic testing

Common Problems and Solutions

Even the best equipment has issues.

Here’s what I see most often:

Problem: Poor Metal Removal

Causes:

- Weak magnets

- Material bed too thick

- Belt speed too fast

Solutions:

- Upgrade to stronger magnets

- Reduce material depth

- Slow down feed rate

Problem: Metal Carryover

Causes:

- Drum speed too fast

- Discharge chute misaligned

- Magnetic arc too wide

Solutions:

- Reduce drum RPM

- Adjust chute position

- Modify magnetic assembly

Problem: Product Contamination

Causes:

- Metal bouncing back

- Improper chute design

- Air currents

Solutions:

- Install splitter plates

- Redesign discharge area

- Add dust collection

Cost Considerations

Let’s talk money.

A quality magnetic drum separator runs $10,000 to $100,000+. The price depends on:

- Size (bigger = more expensive)

- Magnet type (rare earth costs 3x ceramic)

- Housing (enclosed systems cost more)

- Special features (variable speed, instrumentation)

But here’s the thing:

The payback period is usually under 2 years. Sometimes just months.

How?

- Reduced equipment damage

- Less product contamination

- Lower labor costs

- Higher product value

Future Developments

The magnetic separation industry isn’t standing still.

Here’s what’s coming:

Smart Separators

- IoT connectivity

- Predictive maintenance alerts

- Real-time performance monitoring

Advanced Materials

- Stronger permanent magnets

- High-temperature capabilities

- Corrosion-resistant designs

Energy Efficiency

- Regenerative drives

- Optimized magnetic circuits

- Lower power consumption

Making Your Decision

Bottom line?

If you’re handling bulk materials with ferrous contamination, you probably need a magnetic drum separator. The question isn’t if but which one.

Start small if you’re unsure. Rent or lease a unit to test in your application. Once you see the results, you can optimize your permanent installation.

Remember: the best separator is the one that matches your specific needs. There’s no one-size-fits-all solution.

Understanding how does a magnetic drum separator work gives you the power to protect your equipment, improve your product quality, and boost your bottom line. These machines might seem simple, but their impact on modern manufacturing and processing is absolutely massive.