One small but important component that is often overlooked when it comes to maintaining the life of your engine is the oil plug. While a standard oil plug will get the job done, a magnetic oil plug can provide a higher level of protection for your engine. Let’s take a look at the materials used to make a magnetic oil drain plug and see how it differs from a regular oil drain plug.

Why use a magnetic oil drain plug?

Magnetic drain plugs are an innovative product that is similar to regular drain plugs, but with one essential difference: a powerful neodymium magnet is embedded in the tip of the plug. This helps capture fine metal particles in the engine oil, preventing them from recirculating in the engine or transmission oil and causing further wear. Using a magnetic drain plug provides many benefits:

- Extended engine life: By capturing metal shavings and other ferrous debris, magnetic drain plugs help reduce wear on engine components. This means less friction, fewer repairs, and longer engine life.

- Improved oil quality: Keeping metal particles out of the oil improves lubrication, reduces heat, and keeps the engine running smoother overall. For industries that rely heavily on machinery, this means less maintenance downtime and greater operational efficiency.

- Cost savings: While the initial cost of a magnetic drain plug may be slightly higher than a standard drain plug, in the long run it results in less engine wear, fewer oil changes, and less frequent repairs.

- Easy to install and maintain: They install just as easily as regular drain plugs and require no special maintenance, other than checking the magnet for accumulated debris at every oil change.

How does a magnetic oil drain plug work?

Magnetic drain plugs work by using the power of magnets to attract and capture ferrous metal particles in the engine oil.

The neodymium magnets embedded in the drain plug attract tiny metal shavings that naturally occur due to engine wear. This debris can include particles from worn gears, bearings, or any moving metal parts within the engine. Once the metal particles are captured by the magnet, they adhere to the exposed neodymium surface at the top of the plug. When it’s time to change the oil, you can simply remove the plug, wipe off the accumulated debris, and reinstall it. This simple step ensures that your engine remains free of harmful particles, keeping your oil in optimal condition.

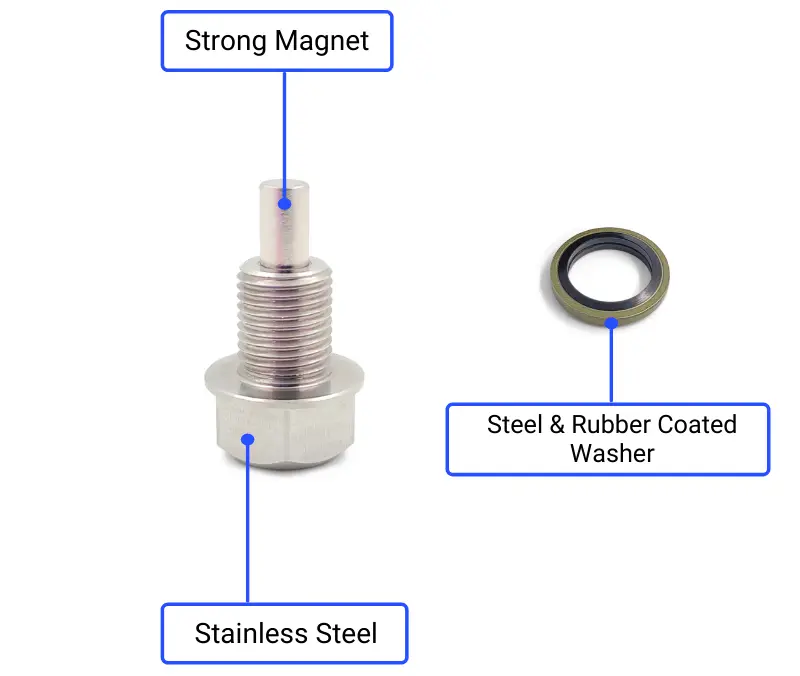

What materials are used to manufacture magnetic oil drain plugs?

Magnetic drain plugs are primarily made of two materials, magnets (neodymium magnets) and metal. The materials used in the manufacture of magnetic drain plugs play a vital role in the effectiveness, durability, and overall performance of the plug.

Magnets

The magnets of high-performance magnetic drain plugs are typically made of neodymium iron boron (NdFeB). Neodymium magnets are known for their high magnetic strength and durability, making them ideal for capturing metal particles in engine oil.

Structural Materials

In addition to the magnets themselves, the structural materials of the plug are equally important. The body of the magnetic drain plug must be strong enough to withstand the high temperatures, pressures, and oily environment within the engine. The main body materials used today include steel, stainless steel, aluminum, and titanium alloys.

- Steel: Carbon steel is one of the most commonly used materials for the body of a magnetic drain plug. It offers excellent strength and durability at an affordable price. Steel drain plugs are strong and durable and can withstand the high temperatures and pressures found in most engines. However, they require a corresponding surface coating treatment to combat corrosion.

- Stainless Steel: Stainless steel is superior to carbon steel in terms of corrosion resistance. Stainless steel is widely used for high-quality magnetic oil drain plugs because it is not prone to rusting, making it ideal for long-term use in environments exposed to oil and moisture.

- Aluminum: Aluminum is often used to manufacture magnetic oil drain plugs for vehicles that require lightweight components. Although aluminum is not as strong as steel, it has excellent corrosion resistance and excellent heat dissipation. This material is a popular choice for high-performance vehicles, where weight reduction is critical.

- Titanium: For those seeking the ultimate in durability, titanium magnetic oil drain plugs are the best choice. Titanium has excellent strength, corrosion resistance, and an extremely high melting point, making it ideal for high-performance engines or custom applications. However, titanium magnetic oil drain plugs are more expensive.

By understanding the materials used in the manufacture of our magnetic oil drain plugs, you can make an informed decision when choosing the right plug for your needs. At Osencmag, we offer customizable options for the materials of construction of our magnetic oil drain plugs. The neodymium magnets used are of the highest quality and can be customized to specific specifications based on operating temperatures. We pride ourselves on providing high-quality magnetic oil plugs made from the best materials. Custom orders ensure that your magnetic oil drain plug is not only effective, but also a perfect fit for your equipment.

What are the different types of magnetic oil drain plugs?

Magnetic oil drain plugs are an important tool for protecting engines in engine oil. Depending on the application, material, and design, these plugs can be divided into various types to meet specific needs. When choosing the right magnetic oil drain plug, recognizing the differences between them can help us make the right choice when choosing the best plug for our vehicle or machinery. Below, we will break down the various types of magnetic oil drain plugs based on material composition, magnet strength, and thread size.

The material of the magnetic oil drain plug has a significant impact on its durability, corrosion resistance, and suitability for different operating conditions. There are 4 common types of magnetic drain plugs according to the material.

- Steel magnetic oil drain plugs: Standard steel oil drain plugs are the most widely used magnetic oil drain plugs and are ideal for most everyday vehicles and machinery. But they need to add a protective coating to resist corrosion, especially when exposed to oil and moisture.

- Stainless steel magnetic oil drain plugs: The anti-corrosion properties of stainless steel ensure that magnetic oil drain plugs can maintain their reliability for a long time. Therefore, these plugs are often used in high-performance vehicles or equipment.

- Aluminum magnetic oil drain plugs: Aluminum oil drain plugs are lightweight, dissipate heat quickly, and are naturally rust-resistant. Therefore, it is popular in high-performance vehicles and high-temperature engines where weight reduction is important.

- Titanium magnetic oil drain plug: Titanium has extremely high toughness and corrosion resistance, which is ideal for high-performance or industrial engines that require reliable and durable parts. Therefore, titanium magnetic oil drain plug is the first choice for optimal durability and strength.

We all know that the strength of the magnets embedded in magnetic oil plugs is critical to effectively capture metal particles. But what you may not know is that the neodymium magnets used in oil plugs come in various strength levels:

- Standard Neodymium Oil Drain Plugs: Common grades of neodymium magnets used in these oil drain plugs include N35, N38, N40, N42, N45, and N52. These magnets are used in most consumer-grade magnetic oil drain plugs. They are strong enough to capture common metal fragments found in everyday vehicles.

- High Temperature Neodymium Oil Drain Plugs: Specific applications require magnets that can withstand higher temperatures without losing their magnetism. High temperature neodymium magnets are ideal for maintaining their magnetic attraction in extremely hot environments.

Magnetic oil drain plugs come in a variety of sizes to suit different types of engines. The thread size must match the oil pan threads to ensure a proper fit and avoid oil leaks.

- Metric Thread Magnetic Oil Drain Plugs: Commonly used in European and Asian vehicles. They are designed to fit metric oil pans and are usually measured in millimeters.

- Standard (SAE) Threaded Magnetic Drain Plugs: More commonly found on U.S. vehicles. These plugs fit oil pans with standard thread sizes (measured in inches).

- Custom Threaded Magnetic Drain Plugs: In some cases, especially special industrial or specialized machinery, a custom thread size may be required.

In addition to material, magnet strength, and thread size, magnetic oil plugs can be categorized based on their specific functional design features.

- Flush Magnetic Oil Drain Plugs: These plugs sit flush with the oil pan, reducing the risk of damage from road debris or other external factors.

- Extended Magnetic Oil Drain Plugs: Extended plugs have a longer neodymium core, providing a larger surface area to capture metal particles. Ideal for engines that generate more metal debris.

When choosing a magnetic oil drain plug, it is important to consider the specific needs of your vehicle or equipment. Factors such as engine type, operating conditions, and maintenance requirements will determine which type of plug is best for you.

Osencmag offers a variety of customizable magnetic oil drain plug manufacturing, various magnetic strengths, thread specifications, and specific designs. Our experienced team can ensure your engine receives the best protection. Whether you need a standard plug for everyday use or a high-performance solution for demanding environments, we are committed to providing quality products that meet your unique needs.

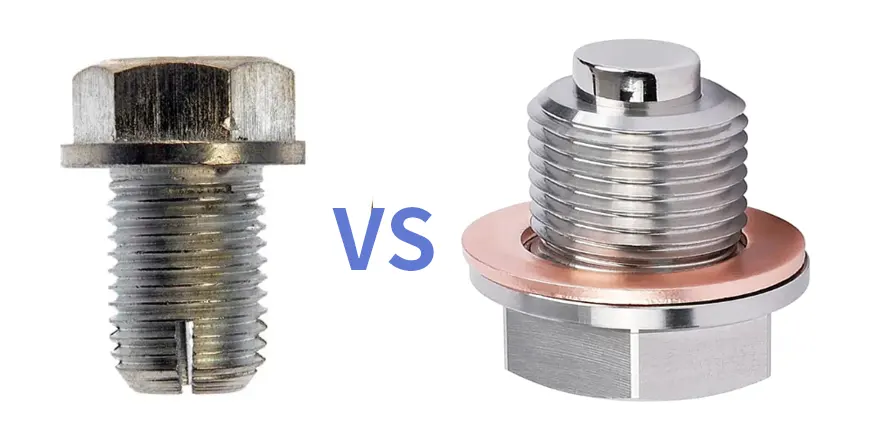

How do magnetic oil drain plugs compare to standard oil drain plugs?

Most vehicles are equipped with an oil drain plug for regular oil changes in the engine. But in recent years, magnetic oil drain plugs have become popular for their unique product advantages. Magnetic oil drain plugs work similarly to standard oil drain plugs, but with an additional permanent magnet that attracts and collects metal debris (iron particles, steel shavings) that may be floating in the engine oil. This extra layer of protection helps prevent these metal particles from circulating in the engine, where they may cause wear or damage.

Let’s take a look at the main differences between magnetic oil plugs and standard oil plugs to understand why investing in magnetic plugs may be a better choice for your engine.

| Magnetic oil plugs vs. standard oil plugs performance comparison | ||

| Feature | Magnetic Oil Drain Plug | Standard Oil Drain Plug |

|---|---|---|

| Primary Function | Captures metallic debris in the oil with a built-in magnet, preventing it from circulating in the engine. | Simply allows oil to drain from the engine during oil changes. |

| Engine Protection | Offers additional protection by removing metal shavings from the oil, reducing wear on engine components. | Does not offer any protection against metal debris in the oil. |

| Durability | Typically made from high-quality materials like stainless steel or aluminum, ensuring long-lasting performance. | Can also be made from durable materials, but lacks the extra debris-catching functionality. |

| Maintenance Benefits | Helps extend the life of your engine by keeping it cleaner and reducing the chance of internal damage. | Provides basic maintenance functions but does not contribute to engine cleanliness. |

| Cost | Generally more expensive due to the added magnet and premium materials used. | More affordable and commonly used in most vehicles by default. |

| Customization Options | Available in various materials (titanium, stainless steel, etc.) and magnet strengths for specific engine types. | Usually comes in standard materials like steel or aluminum without many customization options. |

| Common Applications | Ideal for high-performance, heavy-duty, or older engines that benefit from added protection against wear. | Typically used in standard vehicles where additional protection isn’t prioritized. |

What are the magnetic force specifications for oil drain plugs?

The strength of the magnets within the drain plug directly affects its ability to capture metal debris in the engine oil. Most magnetic oil plugs use neodymium magnets, which are known for their high magnetic strength. Neodymium magnets are classified by grade (e.g. N35, N42, N52, etc.), with higher numbers indicating stronger magnetic forces. For example, a plug with a high-grade neodymium magnet (such as N52) will have a stronger pull, meaning it can attract and hold onto the smallest metal particles floating in the oil. The grade of the neodymium magnet determines the cleaning power of the magnetic oil plug.

The extreme temperatures and pressures that are easily generated in high-performance or industrial engines require consistent magnetic force in magnetic oil plugs. Temperatures generally exceed the temperature resistance limit of the magnets, and demagnetization will occur, affecting the performance of the magnetic oil plug application. Neodymium magnets can be customized to withstand high temperatures (up to 150°C or more for some grades), ensuring reliability in extreme environments.

One of the biggest benefits of a stronger drain plug is that the plug can capture more particles before reaching its maximum capacity. If the magnet is weak, the magnetic oil drain plug will need to be cleaned or replaced because it won’t hold as many metal particles. Stronger magnets provide longer-lasting protection for your engine, which means less frequent maintenance and less worry.

Our neodymium magnets are available in a variety of grades, from N35 for lighter applications to N52 for when maximum magnetic force is needed. We also offer high temperature resistant options, ensuring the magnets will perform reliably even in the most extreme conditions.

Osencmag knows that not all engines are the same, and neither are their magnetic oil drain plugs. That’s why we offer fully customizable production based on customer needs. Whether you need a plug for a high-performance engine, industrial application, or standard vehicle use, we can provide a magnetic oil drain plug with the precise magnetic strength and high temperature resistance to keep your engine running smoothly. If you’re looking to source high-quality magnetic oil drain plugs in bulk for your specific business needs, Osencmag can help. Contact us today to learn more about our products and customization options.

How effective are magnetic oil drain plugs at preventing engine damage?

Magnetic oil drain plugs are highly effective at preventing engine damage. They work by attracting and trapping metal particles that can accumulate in engine oil, such as shavings from gears and bearings. By removing these harmful debris, they help reduce wear and tear on engine components, ultimately extending engine life. In fact, using a magnetic oil drain plug can result in cleaner oil and less frequent repairs, making them a smart investment for anyone looking to protect their engine.

What vehicles and machines commonly use magnetic oil drain plugs?

Magnetic oil drain plugs are commonly used in a variety of vehicles and machines, including cars, trucks, motorcycles, and industrial equipment. They are particularly beneficial in high-performance engines and heavy-duty machinery, where engine wear can be more pronounced. Many automotive enthusiasts and fleet operators choose magnetic oil drain plugs to enhance engine protection, making them a popular choice across diverse applications.

What maintenance is required for magnetic oil drain plugs?

Magnetic oil drain plugs require minimal maintenance. During regular oil changes, simply remove the plug, wipe off any accumulated metal debris, and reinstall it. This straightforward process ensures that the magnet remains effective in capturing new particles. It’s a good idea to inspect the magnet periodically for wear or damage, but overall, these plugs are designed for hassle-free maintenance, providing ongoing protection for your engine.

Can I use a magnetic oil drain plug in all types of engines?

Yes, magnetic oil drain plugs can be used in most types of engines, including gasoline, diesel, and high-performance models. They are compatible with a wide range of vehicles, from everyday cars to heavy-duty trucks and motorcycles. However, always check the manufacturer’s specifications to ensure compatibility. Using a magnetic oil drain plug is a great way to enhance engine protection, regardless of the type of engine you have.

How do I choose the right magnetic oil drain plug for my vehicle?

When selecting a magnetic oil drain plug, consider the size and thread type to ensure a proper fit for your vehicle. Additionally, look for a plug made from durable materials like stainless steel or aluminum for added corrosion resistance. Assess the magnetic strength; stronger magnets can capture more particles. Finally, consider your engine’s operating conditions, such as temperature, to choose a plug that meets your specific needs.