As a magnet with strong magnetic retention and outer protective steel sleeve, pot magnets are widely used in people’s lives and work. Through the previous pot magnet type blog, I believe you have a clear understanding of this durable magnet accessory. And if you have already purchased pot magnets, the next step is to follow me to learn how to properly install and maintain them in order to extend the life of pot magnets. And how to measure their maximum holding force after installation.

How to properly install and maintain pot magnets?

Pot magnets are versatile tools used in a wide range of applications, from industrial settings to home organization. While they may seem simple to use, ensuring their optimal performance and longevity requires proper installation and maintenance.

1.Pre-Installation Preparation

Before you start installing a pot magnet, it’s essential to take a few preparatory steps to ensure a successful and secure application. Skipping this phase can lead to suboptimal performance or, worse, damage to both the magnet and the surface it’s being applied to.

- Clean the Surface:The surface where the magnet will be installed should be clean and free from dust, debris, or moisture. Any particles between the magnet and the surface can reduce the magnetic force. Use a soft cloth to wipe down the area and ensure there is no oil or rust present.

- Check the Magnet for Defects: Inspect the pot magnet for any visible signs of damage, such as cracks, chips, or deformations. Even slight imperfections can affect its performance. At Osencmag, we take pride in producing high-quality pot magnets that are rigorously tested before they leave our facility, ensuring you receive a flawless product every time.

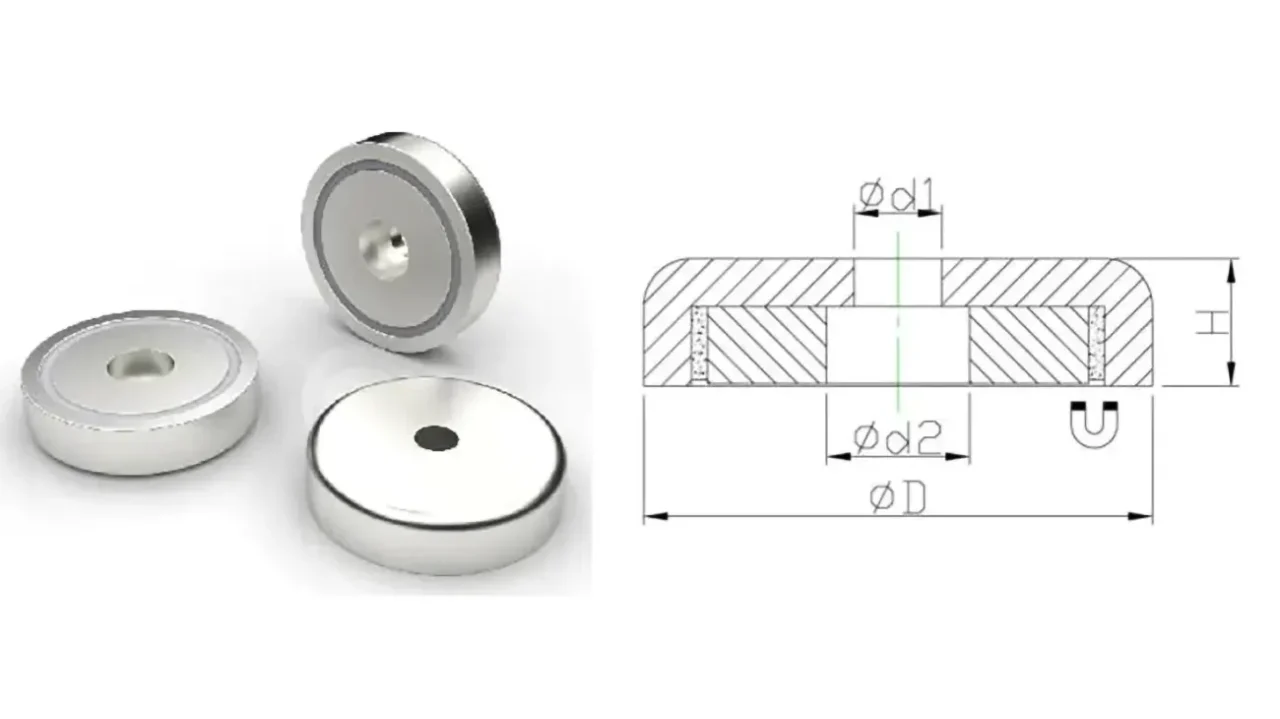

- Choose the Right Mounting Method: Depending on the type of pot magnet and the application, there are different mounting methods to consider, such as using a countersunk hole, threaded stud, or hook attachment. Ensure that you have the right tools and equipment ready before beginning the installation. A poorly chosen mounting method can compromise the stability of the magnet.

2. Proper Installation Techniques

Once you’ve prepared the surface and the magnet, it’s time to install it correctly. Proper installation techniques will help maximize the magnet’s holding power and prevent premature wear or failure.

- Ensure Full Contact:For maximum magnetic force, the entire surface of the pot magnet should make contact with the metal surface. This means avoiding uneven surfaces or air gaps, as even small imperfections can drastically reduce the magnet’s performance. If the surface is slightly uneven, consider using a rubber-coated pot magnet, which can provide a better grip and conform to minor surface irregularities.

- Use the Appropriate Fasteners:When installing pot magnets with threaded holes or studs, use fasteners made from non-magnetic materials, such as stainless steel or brass. Magnetic fasteners can interfere with the magnetic field, reducing the magnet’s effectiveness.

- Install in the Correct Orientation:Pay attention to the direction and orientation of the magnetic field when installing the pot magnet. Ensuring the proper alignment with the surface will enhance the magnet’s holding force. Pot magnets are designed to concentrate the magnetic field on one side, so positioning them correctly is critical.

3. Post-Installation Care

After installation, there are a few steps you can take to maintain the performance of your pot magnet over time. Proper care will not only extend the magnet’s life but also help maintain its holding power in the long run.

- Regular Inspection:Over time, the magnet’s surface can accumulate dirt, rust, or oil, especially in harsh environments. Inspect the magnet regularly to ensure it’s clean and free from debris. Use a soft cloth to wipe it down and remove any buildup. For magnets in outdoor or industrial environments, this should be done more frequently.

- Monitor for Wear and Tear:Keep an eye out for any signs of wear or corrosion, particularly on magnets with coatings such as nickel or rubber. If you notice any damage, it’s important to address it quickly to prevent further deterioration. Replacing a damaged magnet before it fails completely can save time and money in the long run. At Osencmag, we offer a variety of protective coatings to enhance the durability of your magnets and protect them from harsh environmental conditions.

- Reapply Coatings if Necessary:For magnets exposed to moisture or chemicals, coatings such as epoxy or nickel can wear off over time. If you notice the coating deteriorating, reapplying a protective layer can help extend the magnet’s life. At Osencmag, we provide customized coating options based on your application, whether you need additional corrosion resistance or enhanced grip for delicate surfaces.

4. Maintenance and Long-Term Care

Proper maintenance of pot magnets is not a one-time task. Consistent care over the lifespan of the magnet will ensure that it continues to perform as expected. Here are a few long-term maintenance tips:

- Avoid Overloading the Magnet:While pot magnets are designed to hold considerable weight, overloading them can lead to wear and tear or even failure. Always adhere to the weight limits provided by the manufacturer to ensure the magnet’s longevity.

- Protect from High Temperatures:Extreme temperatures can affect a magnet’s holding power, particularly with neodymium pot magnets. Avoid exposing them to temperatures above their maximum working limit, as this can result in a permanent loss of magnetic strength. If your application involves high temperatures, consider using samarium cobalt pot magnets, which are designed to withstand extreme heat. Osencmag offers temperature-resistant options to ensure that your magnets are suitable for challenging environments.

- Store Magnets Properly:When not in use, store pot magnets in a dry, cool environment. If magnets are stacked together, make sure to place spacers between them to prevent chipping or scratching the surfaces.

Proper installation and maintenance are essential to getting the most out of your pot magnets, ensuring they provide reliable retention and durability for your project. At Osencmag, we don’t just provide high-quality pot magnets; we provide expert guidance and solutions tailored to your specific requirements.

How to measure the maximum holding force of pot magnets?

After correctly installing the pot magnet, measuring its maximum holding force can ensure safety during subsequent use. Accurately measuring the holding force can make you worry-free during use.

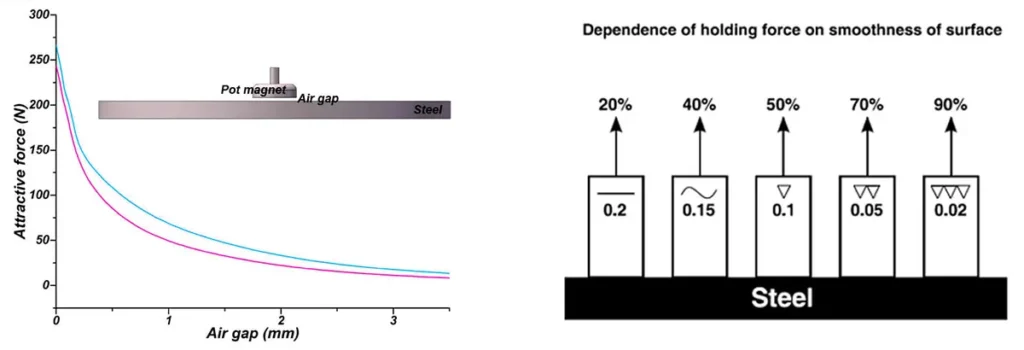

Typically, the maximum holding force of a magnet refers to the maximum vertical weight that the magnet can withstand when applied to an ideal surface under perfect conditions. It is important to understand that this “perfect” condition is usually a clean, smooth, flat, and thick ferromagnetic surface (usually steel). In reality, the surface in most applications may not be perfect, and the direction of the force also involves shear forces (side-to-side movement), which can reduce the effective holding force. Typically, when measuring the holding force of a pot magnet, several factors need to be considered:

- Surface Quality: The test surface must be smooth and clean. Any dirt, rust, or unevenness can drastically reduce the magnet’s holding capacity. For accurate measurements, always use a clean steel surface.

- Material Thickness: Thicker steel enhances the holding power of the magnet, while thinner materials can reduce the measured force. Ideally, the steel surface should be at least 10mm thick for an accurate assessment.

- Air Gaps:Even a tiny air gap between the magnet and the surface (caused by coatings, paint, or rough textures) can decrease the holding power. Ensure that the magnet is in full, direct contact with the surface during testing.

- Temperature:Magnetism is affected by temperature. As the temperature rises, the magnet’s strength can weaken. This is particularly important when testing neodymium magnets, which are more sensitive to heat.

Measuring Holding Force Operational Steps.

The actual process of measuring the holding force of a pot magnet requires specialized equipment, usually a tensile testing machine or a dynamometer. Here is an overview of the steps our production plants take to perform this measurement:

- Step 1: Secure the Magnet

The pot magnet is placed on a steel plate that meets the ideal test surface conditions—clean, smooth, and thick. The steel plate must be securely fixed to prevent any movement during the test. - Step 2: Apply Force

A force gauge or tensile testing machine is used to apply a controlled and consistent force to pull the magnet away from the steel surface. The gauge measures the force required to detach the magnet, which is recorded as the maximum holding force. - Step 3: Record the Data

The force at which the magnet is separated from the steel surface is noted, providing a precise measure of the magnet’s holding capacity. This value can then be compared to the specified holding force listed by the manufacturer.

It’s important to understand that the measured value is the maximum holding force under ideal conditions. In real-world applications, this force may vary due to less-than-perfect conditions like surface irregularities or angled pulls. However, this standardized testing ensures consistency and comparability across different pot magnets.

Measuring the maximum holding force of a pot magnet is a critical step in determining its suitability for a variety of applications. By understanding the factors that influence this measurement, such as surface quality, magnetic material strength, holding material thickness, and ambient operating temperature, you can ensure that you are selecting the right magnet for your needs.

Quality Control and Customization Services at Osencmag

Choosing the right pot magnet often involves more than just selecting an off-the-shelf product. Customizing a magnet to fit your specific environment and application can greatly improve performance and lifespan. At Osencmag, we follow a rigorous quality control process to ensure that the holding force of each pot magnet is tested and verified under ideal conditions. Our production process includes the use of high-precision tensile testing machines to ensure that our magnets meet or exceed the specified holding force. We work closely with our customers to understand the nuances of each application, providing customized testing for specific applications. If your project requires the magnet to operate in a special environment, such as high temperatures or irregular surfaces, we can perform specialized testing to ensure the magnet is up to the task. We are able to adjust magnet grades, surface coatings, manufacturing techniques, and special mounting configurations. This allows us to customize magnetic solutions to your exact requirements, ensuring that you receive a product that is exactly what you need.

Whether you require a standard option or a custom solution, our commitment to quality ensures that each magnet will provide the holding force and reliability you need. Our team is dedicated to working with you from the initial inquiry stage to final product delivery to ensure that your pot magnet not only meets your expectations, but exceeds them. Contact us today to discuss your project and learn how our custom magnet solutions can help you achieve your goals.

What materials are used in pot magnets?

Pot magnets typically use neodymium, ferrite, or samarium cobalt as the magnetic core. The casing is usually made of steel, which enhances the magnet’s holding power by directing the magnetic field to the working surface.

Can pot magnets lose their magnetism over time?

Pot magnets can lose some magnetism, especially when exposed to extreme temperatures or physical damage. However, with proper use and maintenance, like avoiding high heat and harsh impacts, they can retain their magnetic strength for many years.