Magnetic tool racks have revolutionized tool storage, combining convenience, strength, and organization. Learning about the manufacturing process and materials used in magnetic tool racks is key to choosing the right product for your needs. Follow along as I walk you through the detailed process that goes into making a magnetic tool rack, as well as the key materials that contribute to its strength, durability, and performance. We’ll break down how these components work together to create a reliable tool storage solution, while also providing insights into custom options to suit specific needs.

How to make a Magnetic tool holder?

We have explored the types of magnetic tool holders in past articles and compared their advantages over traditional tool storage methods. But how exactly are these magnetic tool holders made? Following along with us to understand the manufacturing process can give you a clearer idea of what to expect in terms of quality, durability, and customization options.

The manufacturing process of a magnetic tool holder involves multiple steps, from selecting the materials to final assembly and testing. To ensure that it meets the functional and aesthetic requirements. At Osencmag, we use high-quality materials and advanced production technology to manufacture magnetic tool holders suitable for various industries. Here are the steps involved in manufacturing magnetic tools.

- Material Selection

We start by selecting high-quality materials. The main component is the magnet itself, which is usually made of neodymium, which is known for its strong magnetic properties. Depending on the intended use of the holder, we choose different grades of neodymium to balance magnetic strength and high temperature resistance. For the base of the holder, durable materials such as stainless steel or aluminum are often used to provide a long-lasting foundation. This ensures that the holder can withstand heavy tools without compromising strength or durability. - Molding and Coating of Magnets

Once the material has been selected, the next step is to shape the magnet. The magnets used in magnetic tool holders are molded through a sintering process, in which magnetic powder is compressed into the desired shape and then heated. After molding, the magnets are coated to protect against corrosion and wear. Common coatings include nickel, epoxy, or rubber, depending on the environment in which the tool holder will be used. Each coating type adds different protection features, such as protection against moisture, chemicals, or physical damage. The customizable coatings provided by Osencmag enhance the durability of the magnets, ensuring that they are suitable for indoor and outdoor applications and harsh industrial environments.

- Making the Base

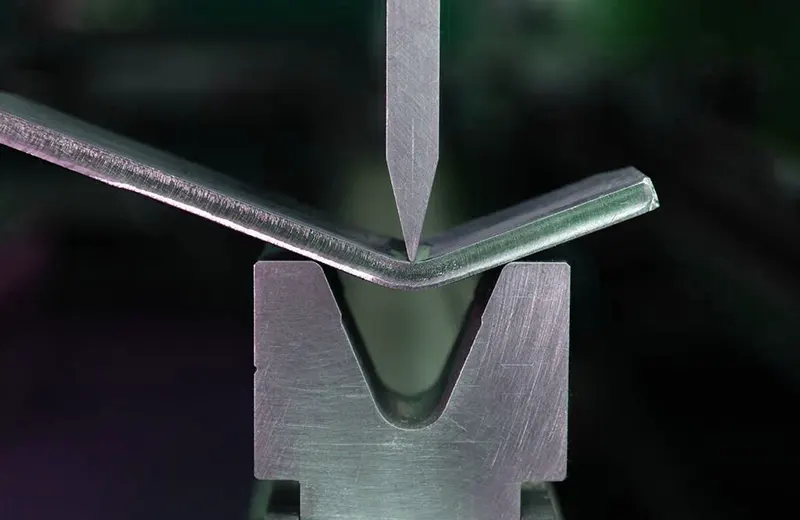

The base of the magnetic tool holder is used to hold the magnets, and its manufacturing needs to be carried out according to the design specifications. This may involve cutting, bending or molding metal to form the desired shape. Magnetic tool holders housings typically come in the form of a bar, rack or tray, each with unique shape and size requirements. Once the base is formed, any necessary mounting holes are drilled to accommodate wall mounting or other mounting methods.

Precision is critical at this stage. The base must be strong and the right shape to support the magnet without affecting its performance. Whether it is a simple tool bar or a more complex tool holder, ensuring the durability of the base is key to making the product durable and effective. We support customers with a one-stop solution from design, prototyping to mass production. - Magnet Embedding

Once the main components of the magnetic tool holder are formed and coated, the next step is to embed or secure the magnets to the base. Depending on the design, the magnets can be glued into pre-cut slots, screwed, or secured using a combination of adhesives and mechanical fasteners. We ensure that the magnets are evenly spaced and securely secured so that they provide consistent magnetic force across the entire holder. Misalignment or improper securing can reduce the effectiveness of the product, so attention to detail is critical. - Surface Treatment

After the magnets are embedded, the entire tool holder may be surface treated to improve its function and appearance. Surface treatments such as powder coating or polishing are usually used to improve the appearance and provide additional protection against rust, scratches, or wear. A durable surface treatment not only protects the tool holder, but also makes it easier to clean and maintain, which is very important in an industrial or workshop environment. We will communicate closely with our customers to give recommendations on the appropriate type of surface treatment based on the customer’s intended application environment.

- Quality Control and Testing

Before a tool holder is ready to ship, it goes through rigorous quality control and testing. We test the magnetic strength to ensure it can safely support the expected weight of the tools. We also conduct other tests that simulate actual use scenarios to check the overall sturdiness and finished product quality. We inspect each tool holder for defects or weaknesses to ensure it meets our strict quality standards.

This step is critical to providing customers with reliable products that meet their specific needs. Whether they are looking for a heavy-duty magnetic holder for industrial use or a stylish design for a home workshop, we can ensure that the final product performs as expected. - Packaging and Delivery

After the magnetic tool holder passes all tests, it is cleaned, packaged, and prepared for shipment. Packaging is designed to protect the product during transportation and often includes custom branding or labeling for bulk orders. Packaging is very safety-oriented to prevent damage during transportation and ensure that the product is intact and ready to use. For some personalized or branded customers, we also provide complete OEM packaging solutions to facilitate their better brand communication.

While these are typical steps in producing standard magnetic tool holders, many customers require solutions tailored to their specific needs. At Osencmag, we excel in mass-producing custom magnetic tool holders. We have the ability to adjust aspects such as size, shape, magnetic force, and finish to create a tool holder that is exactly what the customer requires. Whether you are looking for a specialized tool holder for a specific industry or a retail bulk order, our team is ready to help you.

In short, the process of manufacturing magnetic tool holders requires precision, expertise, and attention to detail at every stage. By understanding how these products are manufactured, you can better understand their quality and durability. Osencmag prides itself on providing high-quality magnetic products that meet the diverse needs of our customers. Contact us today to learn more about our custom manufacturing services and how we can help you find the perfect solution for your tool storage needs.

What materials are best for manufacturing Magnetic Tool Holders?

We already know the entire manufacturing process of magnetic tool holders. But when we talk to customers, we find that customers often struggle with material selection. Now, it’s time to understand the materials used to make magnetic tool holders, which is crucial to ensure that the final product quality matches the intended use. The materials used in magnetic tool holders determine its strength, durability, and overall performance. Choosing the right material is essential to ensure that the tool holder can support various types of tools and withstand daily wear and tear.

Magnets

As the core of every magnetic tool holder, the magnet is the most critical component. The strength and type of magnet used will determine the capacity and holding power of the tool holder. Most of the magnetic tool holders we produce use neodymium magnets, which are rare earth magnets known for their excellent magnetic strength. Neodymium magnets are available in different grades and temperature specifications, of which the most common one is N52. Depending on the weight that the tool holder needs to support, it is important to choose the right grade. For example, a holder for industrial tools may use a higher grade of neodymium magnets to ensure a strong holding force even under heavy loads. Neodymium magnets are much stronger than traditional ferrite magnets, which means they can accommodate heavier tools in a more compact design. Of course, if the customer is particularly looking for economical production, we also support ferrite as the core of the product.

We carefully select the magnet grade for each project and adjust the magnetic strength according to your needs. Whether it is for a light household tool rack or heavy industrial equipment, we can ensure the right balance of strength and performance.

Steel

The next critical material in a magnetic tool holder is the base or the structure that holds the magnets. Steel is one of the most commonly used materials for the base because of its strength and magnetic conductivity. Steel provides a sturdy foundation that allows the magnet to hold securely while also resisting bending, corrosion, or damage. Depending on the environment where the tool holder will be used, the steel base may be coated with a protective layer. For example, powder coating or galvanization can protect the steel from rust, especially in areas with high humidity or exposure to water, such as garages or outdoor workspaces.

We offer a range of surface treatments for steel bases, including powder coating and galvanization, to ensure long-lasting durability even in harsh conditions. These coatings not only protect against rust but also improve the overall look of the tool holder.

Aluminum

While steel is the most common choice, aluminum is sometimes used for magnetic tool holders when a lightweight option is preferred. Aluminum is highly resistant to rust, making it a good option for tool holders that may be exposed to moisture. It’s also easier to work with than steel, allowing for more complex shapes and designs in the holder’s structure. However, since aluminum isn’t magnetic, the design has to incorporate the magnets in a way that maximizes their exposure, such as by mounting them on the outer surface. Aluminum magnetic tool holders tend to be used for more lightweight tools, as they can’t hold as much weight as steel-based holders.

For clients who prioritize weight and rust resistance, we offer aluminum-based designs that balance lightness with functionality. These options are perfect for environments where portability and moisture resistance are key factors.

Plastics and Rubber

Some magnetic tool holders contain plastic or rubber components, especially in custom designs. These materials are often used for tool holders that need extra protection from scratches or impacts, especially for delicate tools or surfaces. For example, rubber-coated magnetic tool holders can be used in automotive workshops to avoid scratching painted surfaces. Plastics can be used to create ergonomic designs that make tool holders easier to grip and use. While plastics and rubber do not have the strength of steel or aluminum, they can provide additional functionality depending on the use case.We are able to create unique, user-friendly designs based on specific customer needs. We offer custom plastic and rubber components for magnetic tool holders, especially for applications where aesthetics or tool protection are important.

While these materials are common in magnetic tool holder manufacturing, each application requires its own unique combination of strength, durability, and customization. At Osencmag, we specialize in custom magnetic tool holders that meet your specific requirements. From selecting the right magnets and base materials to adding protective coatings and ergonomic designs, we ensure that each product meets the highest standards of quality and functionality.

Making magnetic tool holders requires precise material selection, expert craftsmanship, and thorough quality control. If you are looking to purchase magnetic tool holders in bulk or need a custom solution for your brand, you have come to the right place. Contact us today and Osencmag will provide you with products that meet your exact needs with unmatched quality and reliability.

How strong should a Magnetic Tool Holder be for heavy-duty tools?

For heavy-duty tools, a magnetic tool holder should have a pull force of at least 20 to 50 pounds per inch. This ensures that it can securely hold heavier items like wrenches, hammers, or large screwdrivers without slipping off.

The exact strength required depends on the weight and size of the tools you plan to store. For example, each tool over 5 pounds will require a holder with a stronger neodymium magnet, which typically has a higher pull force. Additionally, magnetic tool holders designed for heavy-duty use typically have reinforced backing to withstand pressure and maintain a strong grip. A well-built holder ensures that tools are securely held in place, improving workplace safety and accessibility.

What are the safety considerations when using Magnetic Tool Holders in a workshop?

The main safety issue is making sure the magnetic tool holder is securely mounted and used correctly. Tools can fall if the tool holder is not mounted on a solid surface, or if the magnetic force is too weak to hold heavier tools.

When mounting, place the stand at an easily accessible height to prevent accidents when grabbing or placing tools. Also, keep magnets away from electronic devices: Magnets can interfere with or damage electronic devices, so avoid placing sensitive devices nearby. Regularly check the stand and tools for signs of wear to prevent any accidents.

Can a Magnetic Tool Holder damage electronic devices in the workshop?

Yes, magnetic tool holders can potentially interfere with or damage electronic devices if placed too close. Strong magnets, especially those used in heavy-duty magnetic tool holders, can affect the operation of devices like smartphones, laptops, and digital measuring instruments. To avoid this, it’s best to install magnetic tool holders away from sensitive electronics, or designate a specific area in the workshop where electronics are stored away from magnetic fields. This precaution helps ensure that tools are stored securely while maintaining the integrity of electronic devices in the workspace.

How do you maintain a Magnetic Tool Holder for long-term use?

Maintaining a magnetic tool holder is simple but important for its long-term effectiveness. Start by cleaning it regularly to remove metal dust or debris that might reduce its magnetic strength. Use a damp cloth or mild cleaner to wipe down the surface. If the holder is exposed to moisture, make sure it has a protective coating, like rubber or a corrosion-resistant finish, to prevent rust. Regularly check the mounting hardware to ensure it’s secure, especially if you’re storing heavier tools. Keeping the holder clean and securely fastened will maximize its lifespan and functionality. Detailed maintenance information for magnetic tool holders can be found in our corresponding guide.