Quick Answer

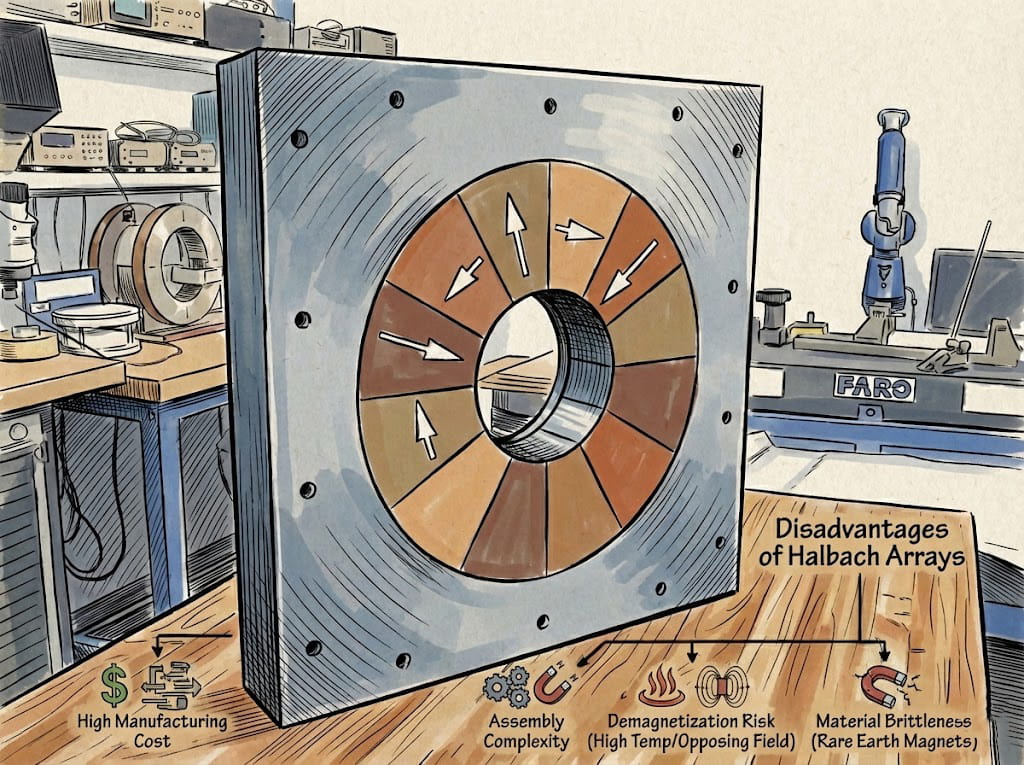

Halbach arrays are complex to assemble because magnets repel each other, requiring precision tools and safety measures. They suffer from self‑demagnetization and perform poorly in high‑temperature applications. While useful in coreless designs or where stray fields must be minimized, they offer no benefit when used with back iron and are often more expensive than conventional arrays.

Halbach arrays are often praised for their one‑sided magnetic fields and compact designs—but they come with serious trade‑offs. In reality, their disadvantages include difficult and hazardous assembly, internal self‑demagnetization, poor high‑temperature performance, and high costs.

As a professional Halbach arrays manufacturer, I wrote this article to break down the five major drawbacks of Halbach arrays, backed by engineering data and real‑world examples. You’ll learn why this magnetic configuration is not a universal upgrade, and discover the specific scenarios where it might—or might not—be worth the investment.

The Halbach Hype vs. Reality

First, a quick refresher.

A Halbach array is a special arrangement of permanent magnets that amplifies the magnetic field on one side while nearly canceling it on the other.

Think of it like a magnetic spotlight.

Instead of shining light in all directions (like a standard magnet), a Halbach array focuses almost all its “magnetic light” in one direction.

The result? A super strong magnetic field where you need it… and almost nothing everywhere else.

On paper, this sounds perfect. And in some cases, it is.

But here’s the thing:

That perfect magnetic spotlight comes with a long list of trade-offs.

Trade-offs that most blog posts and forum threads don’t mention.

Let’s fix that.

5 Disadvantages of Halbach Arrays

Disadvantage #1: It’s a Manufacturing Nightmare

I’m just going to say it:

Halbach arrays are ridiculously hard to assemble.

We’re not talking about “take your time and be careful” hard. We’re talking about “you might need specialized equipment and serious safety gear” hard.

Why?

Because every magnet in a Halbach array is positioned to repel its neighbors.

Imagine trying to put together a puzzle where every piece actively pushes away from the piece next to it. That’s essentially what you’re dealing with.

The Assembly Challenge Breakdown:

- Precision Required: Each magnet needs to be oriented at a very specific angle. Research shows that even a 5-degree error in placement can significantly reduce the overall magnetic field strength. We’re talking about tolerances that often require robotic assembly or expensive jigs.

- Forces at Play: You’re fighting powerful magnetic repulsion forces during the entire process. This isn’t a hobbyist project. It often requires hydraulic clamps, custom fixtures, and strong structural adhesives just to hold everything in place before it’s finally secured.

- Safety Hazard: Those repelling forces mean magnets can suddenly “snap” or shift with tremendous force. I’ve heard stories of fingers being pinched, magnets shattering, and tools being yanked out of hands. Proper training and safety protocols aren’t optional—they’re mandatory.

The bottom line? The increased performance comes at the direct cost of increased manufacturing complexity and cost. For low-volume or prototype applications, this can be a deal-breaker.

Disadvantage #2: The Self-Demagnetization Problem

This is a subtle but critical flaw that many people overlook.

In a standard magnet array, magnets are arranged to support each other. Their fields work together.

In a Halbach array, magnets are arranged in what’s called a direct or quasi-direct repelling condition.

Translation: Each magnet is actively working to demagnetize its neighbor.

Let that sink in.

Your magnetic array is, by design, trying to destroy itself.

To combat this, you must use high-coercivity magnet alloys (like certain grades of Neodymium). These materials resist demagnetization better, but they’re more expensive.

And even then, you’re not out of the woods. This internal demagnetizing field lowers the overall efficiency of the array. You’re starting from a deficit.

Disadvantage #3: High-Temperature Performance is Poor

This disadvantage flows directly from the last one.

All permanent magnets hate heat. As temperature increases, they become more susceptible to demagnetization.

But Halbach arrays are especially sensitive.

Why? Because of that internal self-demagnetizing field I just mentioned. The heat weakens the magnet’s intrinsic resistance, and the neighboring magnets deliver the finishing blow.

In one analysis I reviewed, the operational ceiling for some Halbach configurations was around 1100 K. Beyond that, the magnetic “springiness” of the material degrades, leading to a weaker and less stable field.

Pro Tip: If your application involves any significant heat (like in motors, generators, or aerospace), a conventional magnet assembly with back iron will almost always be more thermally robust than a Halbach array.

Disadvantage #4: The “No Back Iron” Conundrum & Weakened Backside

This is a huge one for motor and generator design.

A major claimed benefit of Halbach arrays is that they eliminate the need for back iron (the ferromagnetic material behind the magnets that provides a return path for magnetic flux). This saves weight and cost.

But here’s what really happens, backed by Finite Element Method Modeling (FEMM) simulations:

1. Halbach + Back Iron = Redundant: If you use a Halbach array with back iron, you see zero improvement in torque or performance over a conventional array with back iron. You’ve just added cost and complexity for no gain.

2. The True Benefit is Niche: The Halbach array only shows a clear advantage (like ~50% more torque in some models) when you completely remove the rotor back iron.

3. The Big Trade-Off: Removing back iron is essentially like having an infinite air gap. And physics tells us that magnetic force drops dramatically with distance. So while you save weight, you often end up with a system that has lower overall torque density unless the gap is perfectly minimized—which is itself a major engineering challenge.

Furthermore, the very principle that makes Halbach arrays great—the one-sided field—is also a limitation. The field on the non-working face isn’t just reduced; it’s significantly weakened. For applications that might utilize both sides of a magnetic field or require specific field symmetry, this is a non-starter.

Disadvantage #5: Astronomical Cost (Material & Labor)

Let’s talk numbers.

The disadvantages of Halbach arrays all converge on one point: cost.

- Material Cost: You need high-grade, high-coercivity magnets. These are not your off-the-shelf components.

- Labor Cost: The assembly requires skilled technicians, specialized tools, and more time.

- Engineering Cost: The design, simulation, and prototyping phase is more complex.

- Scalability Cost: Mass-producing Halbach arrays with consistency is a formidable challenge. Minor variations lead to major performance drops.

When you compare this to a simple alternating-pole magnet array glued to a steel backing plate, the cost differential can be an order of magnitude.

For most commercial applications, this math doesn’t work. The performance boost doesn’t justify the spend.

When Does a Halbach Array Actually Make Sense?

After all that, you might think I’m telling you to never use a Halbach array.

Not true.

There is a time and a place. Understanding the disadvantages of Halbach arrays helps you identify the right application.

Use a Halbach array when:

1. You have an unavoidable operational gap. Data shows Halbach geometries outperform others when a small air gap exists between the array and the workpiece. In direct contact, a conventional alternating-pole array is just as good.

2. You are building a truly coreless system. This is the sweet spot. If you are designing a motor with no iron in the stator or rotor (often to eliminate cogging torque and iron losses), a Halbach array can make a terrible torque density merely… acceptable. It’s a way to salvage performance in an inherently difficult design.

3. Stray field management is your top priority. Applications like magnetic levitation (Inductrack systems) or certain medical devices where containing the field to one side is the critical requirement.

4. Weight is the primary constraint, and you can tolerate the downsides. In some aerospace or satellite applications, saving every gram is worth the cost and complexity.

The Verdict: A Tool, Not a Magic Wand

So, what are the disadvantages of Halbach arrays?

To summarize, they are complex to manufacture, prone to self-demagnetization, sensitive to heat, require niche design conditions to outperform conventional magnets, and are expensive.

In my experience, the hype around Halbach arrays often comes from theoretical models or isolated hobbyist projects. In the pragmatic world of commercial engineering—where reliability, cost, and manufacturability are king—the conventional array with back iron is still the undisputed champion for 90% of applications.

Should you explore Halbach technology? Absolutely. It’s fascinating and powerful.

Should you assume it’s an upgrade for your existing motor or sensor design? Probably not.

The key is to run the numbers for your specific use case. Model it. Calculate the true cost per unit of performance. And let that data—not the forum hype—guide your decision.

Final Thought: Magnetic circuit design is about intelligent trade-offs. The Halbach array offers a unique trade-off: spectacular field concentration on one side for a heap of practical complications. For the rare application where that specific trade-off is worth it, it’s brilliant. For everyone else, it’s an engineering lesson in why simpler is often better.

Remember, asking what are the disadvantages of Halbach arrays is the first step to using them effectively… or knowing when to walk away.