Ever wondered how industries keep their products free from pesky metal contaminants? Or how mining operations sort valuable minerals from waste? Here’s the deal: it all boils down to the magnetic separator working principle. This tech uses magnetic fields to pull apart materials based on their magnetic properties. In this guide, as a professional magnetic drum manufacturer, I’ll break it down step by step, so you can understand exactly how magnetic separators work – and why they’re game-changers in fields like recycling and manufacturing.

Let me explain why this matters. Magnetic separators aren’t just gadgets; they’re essential tools that boost efficiency and safety. Whether you’re in food processing or mineral extraction, grasping the magnetic separator working principle can help you optimize operations. Sound good? Let’s dive in.

Table of Contents

What Is a Magnetic Separator?

First things first: a magnetic separator is a device that sorts materials by exploiting differences in magnetic properties. Think of it as a magnet on steroids, designed to attract and capture ferrous (magnetic) particles from a mix, leaving non-magnetic stuff behind.

In my experience, these separators come in handy across tons of industries. For example, in recycling plants, they pull out iron scraps from waste streams. Or in food production, they snag metal bits that could contaminate products. Without them, you’d have equipment breakdowns or safety hazards left and right.

But here’s the thing: not all magnetic separators are created equal. Some use permanent magnets, while others rely on electromagnets for adjustable strength. The key? They all hinge on the same core idea – magnetic attraction.

The Core Magnetic Separator Working Principle

Okay, let’s get to the heart of it. The magnetic separator working principle relies on magnetic fields to influence materials differently based on their susceptibility.

Here’s a simple breakdown:

Materials fall into three categories when exposed to a magnetic field:

- Ferromagnetic: Strongly attracted (like iron or nickel). These are easy to separate.

- Paramagnetic: Weakly attracted (think aluminum or platinum). Needs a stronger field.

- Diamagnetic: Slightly repelled (such as gold or quartz). These pass through unaffected.

The process kicks off with a magnetic field generated by magnets inside the separator. As your mixture – whether it’s dry powder, slurry, or bulk material – flows through, magnetic particles stick to the magnet or get diverted.

Non-magnetic bits? They keep moving along their path.

Pro Tip: Always match the field’s intensity to your materials. Too weak, and you miss contaminants; too strong, and you waste energy.

In practice, this principle powers continuous operations. For instance, in a drum separator, the drum rotates, picking up magnetic stuff on its surface while non-magnetics fall away. It’s efficient and hands-off.

Step-by-Step: How the Separation Process Works

Want a clear picture? I’ll walk you through the magnetic separation process like I would if we were chatting over coffee.

Step 1: Generate the Magnetic Field. This is where permanent magnets or electromagnets create the force. Electromagnets let you tweak the strength – super useful for varying materials.

Step 2: Feed the Material. Dump your mixture in via conveyor, chute, or pipe. Consistency is key here; uneven flow can mess up separation.

Step 3: Attraction and Diversion. As stuff passes the field, magnetic particles get pulled toward the magnet. It’s like an invisible hand grabbing them. Non-magnetics? They sail right by.

Step 4: Collection. Magnetic material gets scraped off or released into a bin. Non-magnetics go to another. In continuous setups, like overband magnets, this happens non-stop.

But here’s the bottom line: the magnetic separator working principle isn’t magic – it’s physics. The force equation? F = B * (dB/dx) * V * χ, where B is field strength, V is particle volume, and χ is susceptibility. Don’t worry if that’s Greek to you; just know stronger fields mean better pulls.

In my view, testing is crucial. I’ve seen setups fail because the field wasn’t calibrated right. Run trials with your specific mix to nail it.

Types of Magnetic Separators and How They Apply the Principle

Not every separator works the same. Different designs tweak the magnetic separator working principle for specific jobs.

Let’s list out the main types:

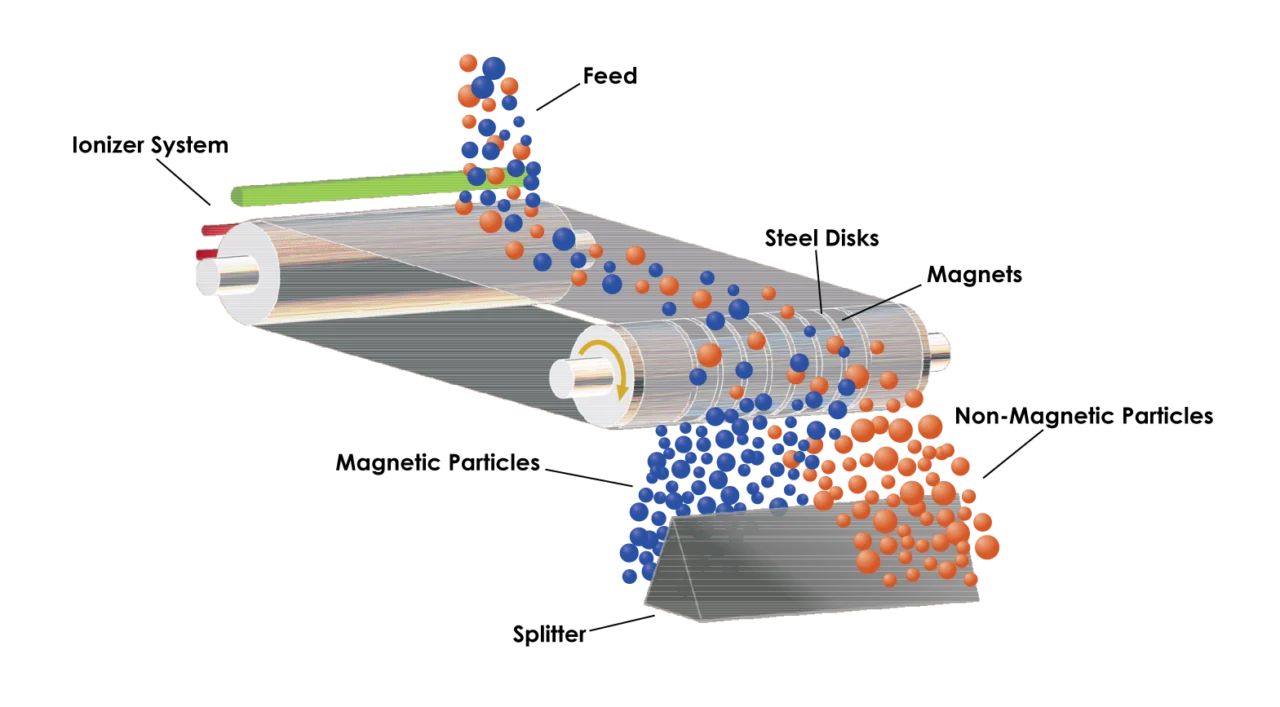

- Magnetic Drum Separators: A rotating drum with internal magnets. As material passes over, magnetics stick to the shell. Great for mineral processing, like separating iron ore. In action, the principle shines – continuous rotation keeps things moving.

- Overband Magnets: Hung over conveyors, these lift tramp iron from bulk flows. Mining loves them for protecting crushers. The working principle? Suspended magnets create a field that yanks metals upward.

- Eddy Current Separators: These use alternating fields to induce currents in non-ferrous metals, repelling them. Recycling pros – think sorting aluminum from plastic. It’s a twist on the basic principle, focusing on repulsion.

- Suspension and Conveyor Belt Separators: Similar to overbands but integrated into belts. Food industry staple for impurity removal.

Each type leverages the core principle differently. For example, eddy currents add a repulsive force for non-magnetics, expanding applications.

In 2025, with smarter tech, we’re seeing AI-tuned fields for even better efficiency. But the fundamentals? They stay the same.

Real-World Applications: Where This Principle Shines

Magnetic separators aren’t theoretical – they’re everywhere. Let’s look at some examples.

In mining and mineral processing, they extract iron ores from slag. One case study: A quarry used drum separators to boost ore purity by 20%, cutting waste.

Recycling? Eddy current models sort metals from e-waste. Stats show they recover up to 95% of non-ferrous metals, per industry reports.

The food and pharmaceutical sectors rely on them for safety. Imagine a grain mill – separators remove nails or screws, preventing recalls. FDA guidelines often mandate them.

Even in chemicals and plastics, they purify raw materials. A plastics plant I know halved defects by adding conveyor separators.

Pro Tip: Match the type to your throughput. High-volume? Go drum. Precision? Eddy current.

These apps show the magnetic separator working principle in action – solving real problems with magnetic savvy.

Advantages and Disadvantages You Need to Know

No tech is perfect. Let’s weigh the pros and cons.

Advantages:

- Efficiency: High separation rates, often 99% for ferromagnetics.

- Capacity: Handles huge volumes – think tons per hour in mining.

- Recovery: Boosts yields, like recovering magnetite in ore processing.

- Eco-Friendly: No chemicals needed; just magnets.

In one study, magnetic separators cut energy use by 30% versus traditional methods.

Disadvantages:

- Maintenance: Magnets wear; cleaning is a chore.

- Limitations: Weak on diamagnetics or fine particles.

- Cost: Upfront investment, especially for high-intensity models.

- Fouling: Non-magnetics can build up, reducing effectiveness.

The key? Regular upkeep. In my experience, scheduling cleanings prevents most issues.

Pro Tips for Optimizing Your Magnetic Separator

Ready to implement? Here are actionable tips.

- Test Your Materials: Run susceptibility tests. Tools like Gauss meters help gauge field needs.

- Calibrate Regularly: Fields weaken over time. Check monthly.

- Integrate Smartly: Pair with screens or crushers for best flow.

- Monitor Performance: Use sensors for real-time data. In 2025, IoT makes this easy.

- Choose the Right Type: Don’t force a drum into a slurry job – go wet separator.

One quick story: A client struggled with low recovery. We switched to an eddy current model, and boom – 15% uplift. Small tweaks, big wins.

Common Mistakes to Avoid

I’ve seen folks trip up here. Don’t.

- Ignoring Particle Size: Too fine? Separation drops. Pre-screen.

- Overloading: Exceeds capacity, efficiency tanks.

- Skipping Maintenance: Leads to failures. Set reminders.

- Wrong Field Strength: Test first.

Avoid these, and your setup will hum.

Future Trends in Magnetic Separation

Looking ahead to 2025 and beyond, things are evolving.

AI integration? It’s coming – auto-adjusting fields based on feed.

Superconducting magnets? Stronger fields, lower energy.

Hybrid systems? Combining with optical sorters for ultimate purity.

Stats predict the market hits $1.5 billion by 2025, driven by recycling demands.

Stay ahead by watching these.

Wrapping Up: Mastering the Magnetic Separator Working Principle

There you have it – a deep dive into the magnetic separator working principle. From basics to advanced tips, this tech is all about harnessing magnetic fields for smart separation. Whether boosting efficiency or ensuring safety, it’s a powerhouse.

Remember: thorough testing and maintenance are your best friends. Apply this, and you’ll see results. Questions? Drop them below. Now go optimize that process!