Let’s talk about magnetic couplings.

If you’re dealing with pumps, mixers, or any rotating equipment that handles nasty chemicals, you’ve probably wondered: “Is there a better way to prevent leaks?”

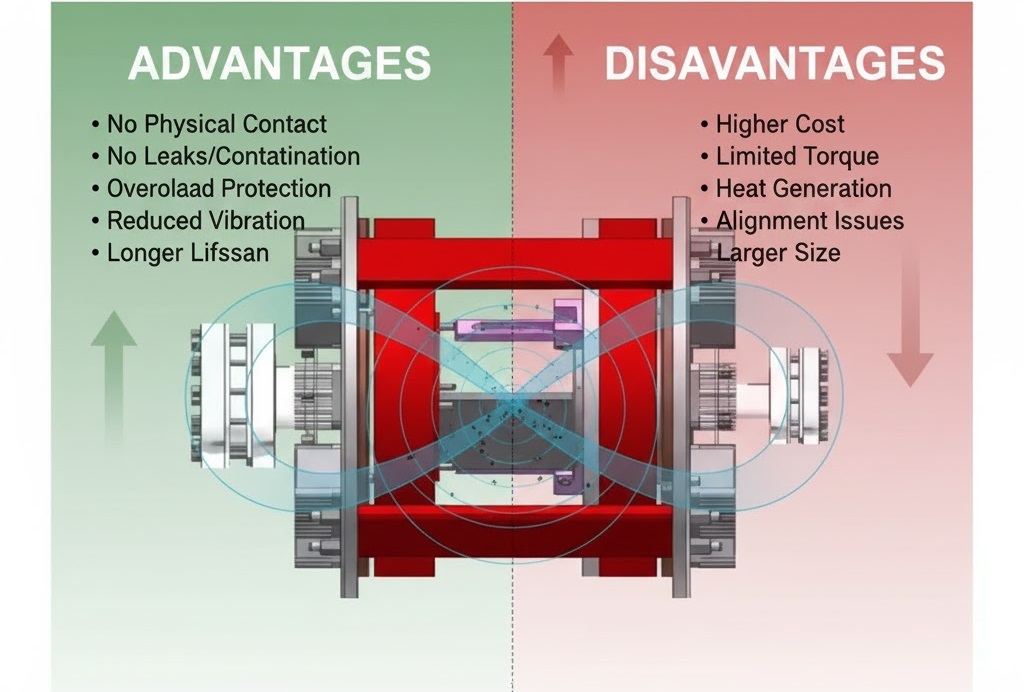

That’s exactly where magnetic couplings come in. The advantages and disadvantages of magnetic coupling systems can make or break your equipment selection decision. And today, I’m going to break down everything you need to know about them.

In fact, as a professional magnetic coupling manufacturer, after analyzing hundreds of industrial applications, I’ve found that choosing the right coupling type can reduce maintenance costs by up to 75%.

But here’s the thing:

Magnetic couplings aren’t perfect for every situation. Sometimes they’re the ideal solution. Other times? They can create more problems than they solve.

So let’s dive into what makes these couplings tick (without any physical contact, of course).

Table of Contents

What Are Magnetic Couplings and How Do They Work?

Before we jump into the pros and cons, let’s get clear on what we’re talking about.

A magnetic coupling is basically a torque transmission device that uses magnetic fields instead of physical contact. Think of it like this: two magnets dancing together without touching.

Here’s the basic setup:

The system has two main parts:

- Outer magnet assembly (connected to your motor)

- Inner magnet assembly (connected to your pump shaft)

Between them? Usually a containment shell that keeps your process fluid completely sealed.

When the motor turns the outer magnets, the magnetic field pulls the inner magnets along. No physical connection needed.

Pretty clever, right?

The magnets are typically made from rare earth materials like neodymium or samarium-cobalt. These aren’t your kid’s refrigerator magnets – they’re SUPER strong and can handle serious torque loads.

The Major Advantages of Magnetic Couplings

Now let’s get into the good stuff. Why would you want to use magnetic couplings in the first place?

1. Zero Leakage (The Big One)

This is the #1 reason people choose magnetic drive pumps.

Traditional pumps use mechanical seals. And mechanical seals? They leak. Maybe not today, maybe not tomorrow, but eventually, they ALL leak.

With magnetic couplings, you get hermetic sealing. The containment shell creates a complete barrier between your nasty chemicals and the outside world.

I’ve seen chemical plants switch to magnetic couplings and eliminate 100% of their seal-related incidents. That’s huge when you’re dealing with:

- Toxic chemicals

- Corrosive acids

- Expensive process fluids

- Environmental hazards

2. Dramatically Lower Maintenance

Here’s something that makes maintenance managers smile:

Magnetic couplings have no wearing parts in contact with each other.

No seals to replace. No packing to adjust. No alignment issues to worry about.

One facility I worked with reported their maintenance hours dropped by 80% after switching to magnetic drive pumps. Instead of monthly seal replacements, they were doing annual inspections.

3. Vibration and Noise Reduction

Because there’s no rigid mechanical connection, magnetic couplings act like a vibration damper.

The magnetic field provides a “soft” connection that:

- Reduces vibration transmission

- Cuts down on noise

- Protects both motor and pump from shock loads

This is especially valuable in applications where noise matters (like hospitals or labs).

4. Built-in Overload Protection

Here’s a feature that’s saved countless motors:

When the load gets too high, magnetic couplings simply slip. The magnets decouple, and your motor keeps spinning freely.

It’s like having a built-in safety valve. No burned-out motors. No damaged equipment.

Sure, you’ll need to stop and restart to re-couple, but that’s way better than replacing a fried motor.

5. Perfect for Hazardous Environments

Need to pump something explosive? Magnetic couplings eliminate a major ignition source – the mechanical seal.

No friction means no heat generation at the seal face. This makes them ideal for:

- Refineries

- Chemical plants

- Pharmaceutical facilities

- Any ATEX-rated zones

The Significant Disadvantages of Magnetic Couplings

Alright, time for the reality check. Magnetic couplings aren’t perfect. Here are the downsides you need to know about:

1. The Price Tag (Ouch)

Let’s not sugarcoat it: magnetic couplings are expensive.

A magnetic drive pump can cost 2-3x more than a traditional sealed pump. Those rare earth magnets? They’re not cheap. And the precision manufacturing required? That adds up too.

For small pumps, you might be looking at a few thousand dollars extra. For larger ones? We’re talking tens of thousands.

2. Power and Size Limitations

Here’s where physics becomes a problem:

Magnetic coupling efficiency drops as size increases. The bigger the coupling, the larger the air gap needs to be. And larger gaps mean weaker magnetic fields.

This creates practical limits:

- Most magnetic drive pumps top out around 300-400 HP

- Torque transmission has hard limits

- Large couplings become prohibitively expensive

If you need to move serious power, traditional couplings might be your only option.

3. Heat Generation (The Hidden Enemy)

Those eddy currents I mentioned? They generate heat. Sometimes a LOT of heat.

The containment shell acts like an induction cooktop, heating up as the magnets spin past. This heat can:

- Boil your process fluid

- Demagnetize your magnets

- Create hot spots that cause product degradation

I’ve seen pumps where the fluid literally baked onto the inner surfaces, creating a crusty mess that eventually seized everything up.

4. Can’t Handle Solids

This is a deal-breaker for many applications:

Magnetic drive pumps HATE solids.

Even small particles can:

- Jam the tight clearances

- Wear out the sleeve bearings

- Accumulate around the magnets

Most manufacturers recommend less than 1% solids, with particle sizes under 100 microns. That eliminates a lot of applications right there.

5. Temperature Sensitivity

Remember those powerful magnets? They have an Achilles heel: temperature.

Most rare earth magnets start losing strength above 80°C (176°F). By 150°C (302°F), they can permanently demagnetize.

This means:

- Limited use in high-temperature applications

- Risk of failure if run dry

- Need for temperature monitoring

Magnetic Couplings vs. Other Options

So how do magnetic couplings stack up against the alternatives?

vs. Direct Drive Couplings

Direct mechanical couplings are simple and efficient. But they can’t provide the hermetic sealing that magnetic couplings offer.

Choose direct drive when:

- Leakage isn’t a concern

- You need maximum efficiency

- Cost is the primary factor

Choose magnetic when:

- Zero leakage is mandatory

- You’re handling hazardous materials

- Maintenance reduction justifies the cost

vs. Fluid Couplings

Fluid couplings use hydraulic fluid to transmit torque. They’re great for high-power applications but can’t match the sealing capability of magnetic systems.

The main differences:

- Fluid couplings handle much higher power

- Magnetic couplings provide better sealing

- Fluid couplings need regular fluid changes

Real-World Applications That Work (And Don’t Work)

Let me share some specific examples of where magnetic couplings shine – and where they don’t.

Perfect Applications:

Chemical Transfer Pumps: Moving concentrated acids? Magnetic drive pumps are often the only safe option. No seals means no leaks, period.

Pharmaceutical Processing: Need to maintain sterility? The hermetic seal prevents contamination in both directions.

Cryogenic Service: Handling liquid nitrogen or other super-cold fluids? Magnetic couplings eliminate seal problems at extreme temperatures.

Terrible Applications:

Slurry Pumping: Forget it. Those solids will destroy a magnetic drive pump faster than you can say “maintenance nightmare.”

High-Temperature Services: Pumping fluids above 150°C? The magnets won’t survive. Stick with traditional sealed pumps.

High-Power Requirements: Need to move 500+ HP? Magnetic couplings become impractically large and expensive.

Making the Right Choice

So when should you seriously consider magnetic couplings?

Ask yourself these questions:

- Is preventing leakage worth the extra cost? If a leak could shut down your plant or harm people, the answer is probably yes.

- Can you live with the power limitations? If you need less than 300 HP, you’re probably fine.

- Is your fluid clean and particle-free? Solids are a deal-breaker for magnetic drives.

- What’s your temperature range? Stay below 150°C for reliable operation.

- How much does maintenance downtime cost you? Factor in the reduced maintenance requirements.

The Bottom Line

The advantages and disadvantages of magnetic coupling systems come down to your specific application needs.

They’re not a universal solution. But for the right applications – handling dangerous chemicals, maintaining sterility, or eliminating maintenance headaches – they can be absolute game-changers.

I’ve seen facilities transform their operations by switching to magnetic drive pumps. No more middle-of-the-night seal failures. No more environmental incidents. No more constant maintenance.

But I’ve also seen companies waste money on magnetic couplings where traditional seals would have worked fine.

The key is understanding both the benefits and limitations, then matching them to your specific needs.

Remember: the best coupling is the one that keeps your process running safely and reliably. Sometimes that’s magnetic. Sometimes it’s not.

Either way, now you’ve got the knowledge to make the right choice.