Ever wondered how pumps can handle dangerous chemicals without a single drop leaking out?

The secret lies in magnetic couplings – a clever piece of engineering that transfers power between shafts without any physical contact whatsoever. If you’re dealing with hazardous fluids, aggressive chemicals, or need a completely sealed system, understanding how does a magnetic coupling work can be a game-changer for your applications.

Here’s the deal:

Traditional mechanical couplings need direct contact between parts. That means seals. And seals eventually fail.

But magnetic couplings? They use invisible magnetic forces to spin equipment through solid barriers. No contact. No seals. No leaks.

As a professional magnetic coupling manufacturer, let me break down exactly how a magnetic coupling works and why it might be the solution you’ve been looking for.

What Exactly Is a Magnetic Coupling?

Think of a magnetic coupling as two synchronized dancers that never actually touch.

You’ve got:

- A driving shaft (connected to your motor)

- A driven shaft (connected to your pump or equipment)

- Permanent magnets on both sides

- An air gap or barrier between them

The motor spins the driving side. The magnets create a magnetic field. And boom – the driven side rotates in perfect sync.

No belts. No gears. No physical connection at all.

The best part? You can put a solid wall between the two halves, and they’ll still work perfectly. That’s why chemical plants love these things.

The Science Behind Magnetic Drive Systems

Here’s where it gets interesting.

Remember playing with magnets as a kid? How opposite poles attract and same poles repel?

That’s exactly what’s happening here – just way more sophisticated.

The Basic Physics

When you arrange permanent magnets in a circle with alternating north and south poles, you create a rotating magnetic field.

Place another set of magnets nearby, and they’ll want to align with that field.

Start spinning the first set, and the second set follows along like a loyal puppy.

It’s that simple. And that powerful.

Torque Transmission Without Contact

The real magic happens in the torque transmission.

As the driving rotor turns, each north pole pulls on the nearest south pole of the driven rotor. At the same time, it pushes away from the north poles.

This creates a continuous rotational force – or torque – across the gap.

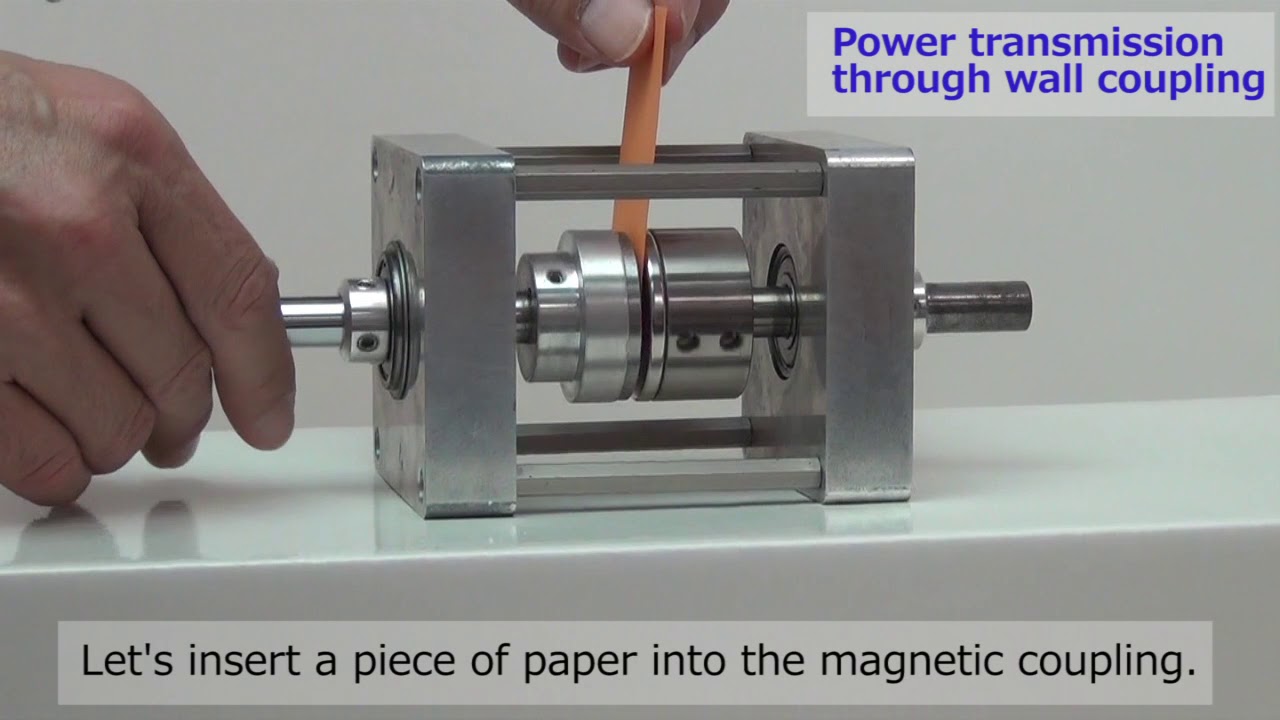

The craziest part? This works through non-magnetic materials.

Stainless steel? No problem.

Plastic? Sure thing.

Even ceramic barriers? Absolutely.

As long as the material isn’t magnetic, the field passes right through.

Components That Make It All Work

Let’s break down the key parts:

1. The Outer Rotor (Driver)

This connects to your motor and contains high-strength permanent magnets arranged in a specific pattern. Usually made from:

- Neodymium (super strong but temperature sensitive)

- Samarium cobalt (less strong but handles heat better)

2. The Inner Rotor (Driven)

Connected to your pump impeller or whatever you’re driving. Also packed with magnets in a matching pattern.

Pro tip: The number of magnetic poles matters. More poles = smoother operation but lower maximum speed.

3. The Containment Shell

This is the secret sauce for hermetic sealing.

It’s a non-magnetic barrier (usually stainless steel) that sits between the rotors. The driven side stays completely isolated from the outside world.

No dynamic seals needed. Just static O-rings that last practically forever.

4. The Air Gap

The space between components is critical. Too big, and you lose torque. Too small, and thermal expansion causes problems.

Most designs use 2-8mm gaps. It’s a balancing act between power and practicality.

Why Magnetic Couplings Beat Traditional Seals

I’ve seen countless pump failures due to seal problems. Here’s why magnetic drives are often the better choice:

Zero Leakage – Guaranteed

Traditional seals wear out. It’s not if, but when.

Magnetic couplings? There’s literally nothing to leak through. The containment shell creates a permanent barrier.

This is huge for:

- Toxic chemicals

- Expensive fluids

- Environmental compliance

- Safety regulations

Built-In Overload Protection

Here’s something cool:

If your pump jams or the load gets too high, magnetic couplings simply slip. The magnets decouple, and the motor keeps spinning harmlessly.

No burnt motors. No stripped gears. No catastrophic failures.

Once you clear the blockage, they automatically re-sync. It’s like a magnetic circuit breaker.

Vibration Isolation

The magnetic field acts like a flexible coupling, dampening vibrations between the motor and driven equipment.

Result?

- Longer bearing life

- Quieter operation

- Less stress on foundations

- Smoother performance

Maintenance? What Maintenance?

No wearing parts means virtually no maintenance.

I’ve seen magnetic drive pumps run for 10+ years without anyone touching them. Try that with a mechanical seal.

Real-World Applications That Rely on This Technology

Let me share some examples of where magnetic couplings really shine:

Chemical Processing Plants

Handling acids, solvents, and other nasty chemicals? Magnetic drive pumps are the industry standard.

No shaft seals = no emission points = happy environmental inspectors.

Pharmaceutical Manufacturing

When you’re making life-saving drugs, contamination isn’t an option. Magnetic couplings provide complete isolation between the product and the outside world.

Plus, they’re easy to clean and sterilize.

Food and Beverage Production

Similar story here. You want your chocolate syrup pump completely sealed from the motor area.

Magnetic couplings make it happen without complex sealing systems.

High-Temperature Applications

Some processes run hot. Really hot.

Special high-temperature magnetic materials can handle up to 300°C (572°F) while maintaining full torque capacity.

Cryogenic Systems

On the flip side, magnetic couplings work great in super-cold applications too. No seals to freeze or become brittle.

Design Considerations You Need to Know

Before you rush out and specify magnetic couplings everywhere, here are some things to consider:

Torque Limitations

Magnetic couplings can’t match the torque density of mechanical couplings.

For the same size, you’ll get less torque. That means bigger equipment for high-torque applications.

Rule of thumb: If you need more than 500 Nm of torque, carefully evaluate your options.

Temperature Effects

Standard neodymium magnets start losing strength above 80°C (176°F).

You’ve got options:

- Samarium cobalt for temperatures up to 300°C

- Cooling jackets for the coupling area

- Oversizing to compensate for temperature losses

Speed Constraints

High speeds create eddy currents in nearby metals, generating heat and reducing efficiency.

Most magnetic couplings top out around 3,600 RPM. Some special designs can go higher, but it gets expensive fast.

Initial Cost

Let’s be honest – magnetic couplings cost more upfront than traditional couplings.

But factor in:

- Zero seal replacements

- No leak cleanup

- Reduced downtime

- Longer equipment life

The payback period is usually 1-2 years in demanding applications.

How to Choose the Right Magnetic Coupling

Here’s my process for selecting magnetic couplings:

1. Define Your Requirements

- Maximum torque needed

- Operating speed range

- Temperature extremes

- Chemical compatibility

- Space constraints

2. Calculate Safety Factors

I always recommend 1.5-2x safety factor on torque ratings. Better to have excess capacity than deal with slippage.

3. Consider Your Environment

Explosive atmospheres? High humidity? Outdoor installation? These factors affect material selection and design features.

4. Think Long-Term

The cheapest option rarely provides the best value. Consider total lifecycle costs, not just purchase price.

Installation Tips for Success

Getting installation right is crucial. Here’s what I’ve learned:

Alignment Matters (But Not As Much)

Magnetic couplings tolerate misalignment better than rigid couplings. But don’t get sloppy.

Aim for:

- Angular misalignment < 3°

- Parallel offset < 0.25″

- Axial float ± 2mm

Check Your Air Gap

Measure the gap between rotors at multiple points. Variations over 30% indicate problems.

Temperature Considerations

Allow for thermal expansion. What fits perfectly cold might bind when hot.

Test the Breakaway Torque

Before putting into service, manually check the torque required to break the magnetic coupling. This becomes your baseline for monitoring magnet condition.

Troubleshooting Common Issues

Even the best technology can have problems. Here’s how to diagnose magnetic coupling issues:

Sudden Loss of Drive

Usually means you’ve exceeded the coupling’s torque limit. Check for:

- Pump blockages

- Bearing failures

- Process changes increasing load

Reduced Performance Over Time

Could indicate:

- Magnet degradation (rare but possible)

- Increased air gap from wear

- Temperature damage to magnets

Unusual Noises

Magnetic couplings should run silently. Noises suggest:

- Misalignment

- Loose components

- Foreign material in the air gap

The Future of Contactless Power Transfer

Magnetic coupling technology keeps evolving. Here’s what’s coming:

Smart Couplings

Integrated sensors monitoring:

- Torque transmission

- Temperature

- Vibration

- Slip detection

All feeding into predictive maintenance systems.

Advanced Materials

New magnet formulations promise:

- Higher temperature capability

- Increased torque density

- Better corrosion resistance

- Lower cost

Expanded Applications

I’m seeing magnetic couplings pop up in:

- Electric vehicle cooling pumps

- Renewable energy systems

- Aerospace applications

- Medical devices

The technology is proven. Now it’s spreading everywhere.

Making the Right Choice for Your Application

So, should you use magnetic couplings?

If you answered yes to any of these, absolutely consider them:

- Zero leakage is critical

- You handle dangerous fluids

- Maintenance access is difficult

- Seal failures cause major problems

- You need overload protection

The higher upfront cost pays for itself through reliability and safety.

The Bottom Line

Understanding how does a magnetic coupling work opens up new possibilities for fluid handling and power transmission.

The technology is elegantly simple – using magnetic fields to transfer torque without physical contact. Yet the benefits are profound: zero leakage, minimal maintenance, and inherent safety features that mechanical seals simply can’t match.

Whether you’re pumping aggressive chemicals, maintaining sterile processes, or just tired of replacing failed seals, magnetic couplings offer a proven solution.

The key is matching the technology to your specific needs. Get that right, and you’ll wonder why you didn’t switch sooner.