In the field of precision machining, the importance of ensuring that workpieces are machined safely and reliably cannot be overstated. As machining practitioners, we all know that the accuracy of operations directly affects product quality and operating efficiency. Magnetic chucks, as commonly used instruments and equipment control devices for fixing ferromagnetic workpieces in modern industry, play an important role in many mechanical processing fields.

What Types of Magnetic Chucks are There?

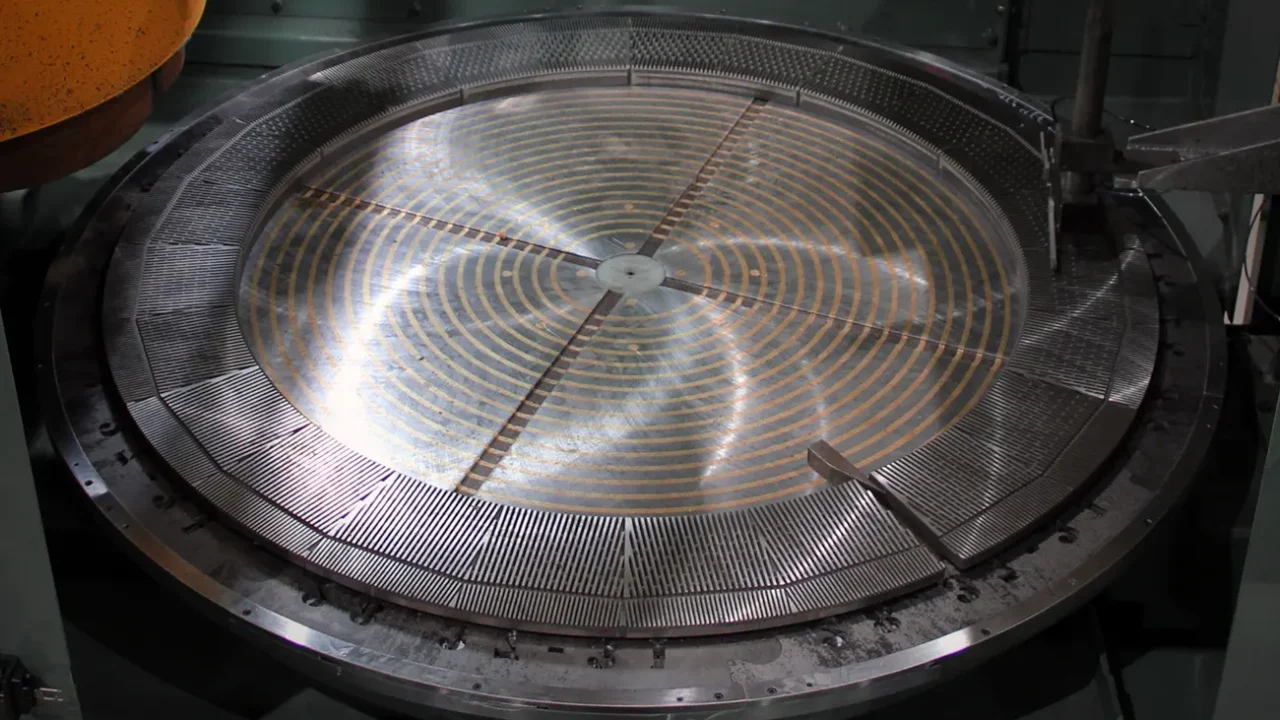

Magnetic chucks are generally rectangular or disk-shaped, and use magnetic force to hold ferromagnetic workpieces tightly. They are mostly used in surface grinders, milling machines, lathes, CNC machine tools, machining centers, etc. Of course, there are some rotary machining processes where a round magnetic chuck would be more convenient. In addition to distinguishing them by appearance, suction cups also need to be divided into three types: electromagnetic suction cup, permanent magnetic suction cup and electro-electric permanent magnetic chuck according to different sources of magnetic force. Different chuck types directly affect processing efficiency, workpiece stability and even long-term costs.If you are responsible for purchasing magnetic chucks recently, you may get scolded by the BOSS if you do not understand the difference between them. Come on, let me take you through them so you can make an informed choice.

Permanent Magnetic Chucks.

The permanent magnet chuck relies on high-strength permanent magnet materials to generate a constant magnetic field. Because these chucks do not require any power supply, they are very energy efficient and reliable, making them ideal for small to medium-sized machining operations. But this magnetic chuck cannot clamp heavy workpieces because it does not have any ability to adjust the strength of the clamping force. Because the magnet is permanent, the chuck provides consistent and stable holding force.

There are permanent magnets arranged neatly in the body, and the magnets are separated by non-magnetic materials. When the permanent magnet is aligned with the magnetic conductor on the suction cup panel, the magnetic lines pass through the workpiece, forming a closed loop and sucking the entire workpiece tightly. When the handle is rotated so that the permanent magnet and the magnetic conductor are staggered, the magnetic field lines no longer pass through the workpiece, and the workpiece can be removed. The alignment of the magnetic poles determines the state of the magnet (whether it is open or closed), and a simple on/off lever controls the magnetic force to instantly lock and release the workpiece.

Advantage:

- No electricity consumption, no additional electricity expenditure required;

- Can be easily installed and quickly removed and moved;

- No heat is generated, ensuring precise processing;

- There is no risk of workpiece movement due to power outage;

- Long service life;

Limit:

- Fixed holding power;

- Not suitable for very large workpieces;

- Due to the need for manual mechanical switches, it is not suitable for automated production processes;

- It uses permanent magnets and has limited temperature resistance;

Electromagnetic chucks.

The body of the electromagnetic chuck is equipped with multiple sets of coils. When direct current (DC) is passed through, a magnetic field is generated to fix the workpiece. Unlike permanent suction cups, electromagnetic suction cups rely entirely on continuous electricity to maintain magnetism.

After energization, the coil in the chuck will be magnetized by the current to generate a magnetic field. The electromagnetic chuck is activated by the control unit and by increasing or decreasing the current, the strength of the clamping force can be adjusted. After power is off, the magnetism will completely disappear and the metal parts on the chuck surface can be released. Compared with permanent magnetic chucks, this chuck has greater power and can clamp irregular-sized workpieces, making it the first choice for flexible precision machining.

Advantage:

- Can generate a very strong magnetic field and provide strong holding power;

- Adjustable magnetic force is suitable for different workpiece materials and thicknesses;

- Operations can be manual, automatic or combined;

- Can be integrated with CNC machines and robotic systems;

- Any size can be made according to the size of the workpiece;

Limit:

- Magnets require a continuous power supply, and interruptions in power can result in loss of holding power;

- Backup power is also often required for safety reasons;

- Continuous use of electricity increases energy bills;

- Prolonged use will generate heat, affecting performance;

- The current in the coil generates heat, which limits accuracy;

Electric permanent Magnetic Chucks.

The electro-permanent magnet chuck combines the safety of permanent magnets with the controllability of electromagnets, and has the advantages of both. It is based on the ability of ferromagnetic materials to become permanent magnets under the brief action of strong direct current. Electromagnetic chucks only require electricity to activate and deactivate, not to hold the workpiece. If there is a power outage, the suction cups will not release the parts.

The electropermanent magnet chuck contains a number of steel poles, each alternating between a north and south pole, with two magnets sandwiched between the poles. There is an electric coil around each magnet that can quickly reverse the polarity of the magnet. Full magnetic power is achieved when both sets of magnets have the same polarity. When the two sets of magnetic fields have opposite polarity, they cancel each other out and the magnet surface will fall off.

Advantage:

- Only uses electricity during activation and deactivation, minimal power consumption;

- Adjustable magnetism allows its application in automated systems;

- There is no risk of accidental release even if the power is cut off;

- Stronger clamping force;

- The temperature is not easy to change, reducing the impact on the accuracy of the workpiece;

Limit:

- The initial investment is higher;

- The production process is complex and requires specialized control units and occasional calibration;

- When the control unit fails, the load will also remain clamped;

Typically if you just need a simple, low maintenance and cost effective option, permanent magnetic chucks are the first choice. If adjustable holding force is required for precision machining, an electromagnetic chuck would be more suitable. But if you want the most powerful, safest and most energy-efficient combination, then it must be an electric permanent magnetic chuck.

This is only a preliminary selection direction. During the actual purchase of magnetic chucks, many factors need to be considered based on actual conditions. Continue reading below.

How to Choose the Right Magnetic Chuck?

Choosing a suitable magnetic chuck should not only focus on the chuck, but should also take into account all factors involved in the entire processing (workpiece factors and external factors). All things are interrelated in order to have an effect. If you’ve ever struggled with weak clamping force, workpiece movement, or choosing between permanent, electromagnetic, and electro-permanent chucks, don’t worry. The key is to know what really matters in the setup you’re facing.

Workpiece material:

The first thing to consider is the workpiece material. Not all metals behave the same in magnetic fields, and it would be unintended to assume that any steel would be affected by magnetism. Mild steel and cast iron are highly magnetic and ideal for most magnetic chucks, but high carbon steel or alloy materials (such as tool steel) may not be attracted well due to their lower magnetic permeability. If you’re working with non-magnetic metals such as aluminum, brass or titanium, standard magnetic chucks won’t work and traditional mechanical clamps or vacuum chucks will need to be resorted to. Always remember to evaluate the material’s response to magnetism before using a chuck.

Workpiece size, shape and surface contact:

Flat, thick magnetic workpieces can be placed securely on the magnetic chuck and receive strong and even clamping force. But small parts or irregularly shaped workpieces may require radial pole chucks or additional magnetic fixtures to maintain stability. Maximizing the contact area is the key to increasing the blessing power. If the part is too thin, the magnetic field may not penetrate deeply enough, and then a fine pole chuck is needed – because fine pole chucks have closely spaced magnetic poles and can better grip the workpiece.

Processing needs:

Different processing requirements determine the strength and type of magnetic chuck required. Light surface grinding is relatively easy, and ordinary fine pole permanent magnetic chucks can do the job. However, when performing heavy milling, deep drilling or powerful cutting, the force will be very large, and a powerful electromagnetic or electro-permanent magnetic chuck with deep magnetic penetration is needed. Part shifting during cutting is a very terrible thing. Selecting a chuck with sufficient holding force can maintain accuracy and avoid rework.

Maintaining balance:

Don’t be intimidated by the “Processing needs” I mentioned above and make you think “the bigger the clamping force, the better”. In fact, too much clamping force can make it difficult to remove parts and even cause thin materials to warp. Our goal is to match the strength of the chuck to the workpiece requirements. When processing high-precision parts, the adjustable electromagnetic chuck can adjust the force to prevent deformation. For heavy workpieces that need to withstand extreme cutting forces, it is safer to choose magnetic chucks with deep magnetic penetration and strong gripping force. Balancing holding force according to workpiece type and processing needs can help improve work efficiency.

Production scale:

When performing batch machining, no one wants to repeatedly stop the machine to adjust the chuck. In this case, electromagnetic chucks and permanent magnetic chucks can achieve more efficient production without stopping the machine. But if it is only a small batch processing or occasionally uses a magnetic chuck to assist work, a simple permanent magnetic chuck may be more cost-effective.

Device compatibility:

Modern machining tables are a large and diverse family in terms of size, installation methods or control system integration. For CNC automation, choosing an electromagnetic chuck with programmable control settings allows for seamless operation. Measure the size of the machine table to ensure that subsequent magnetic chuck purchases will fit securely and will not dangle. Before purchasing, carefully checking the compatibility of the magnetic chuck with the table can avoid unnecessary trouble and waste.

Application environment:

Magnetic chucks are very reliable, but they don’t work in a vacuum. High temperature environments weaken the magnetic field, especially for permanent magnetic chucks. If the work shop where you plan to use the chuck has strong electromagnetic field interference, it is strongly recommended that you choose an electromagnetic chuck. In a shop with excessive amounts of dust, coolant, or metal shavings, the dial material and protective coating of the magnetic chuck will need to be focused on. Although environmental factors are not a priority when selecting a chuck, they can have a big impact on the chuck over the long term.

In short, when we purchase a magnetic chuck, we cannot just choose the strongest magnetic chuck, but find the chuck that best suits the target workpiece material, processing needs and production workflow. Mismatched selections can lead to unnecessary downtime, wasted resources and even security risks. If you are still not sure which magnetic chuck you need, you can consult us immediately. We will help you analyze objectively from our own professional perspective. Additionally, our design and production teams support custom magnetic chucks to help companies optimize their machining operations to increase efficiency and accuracy.

FAQs

How to maintain magnetic chucks?

Keeping it clean and dry, wiping the surface and applying anti-rust oil after each use can effectively extend the life of the magnetic chuck. Electromagnetic chucks require regular inspection of wiring. If you want to know more detailed maintenance knowledge, you can leave us a message and we will consider publishing an issue.

Can magnetic chucks hold non-magnetic materials?

No, standard magnetic chucks can only clamp ferrous metals such as steel. If the machining process requires clamping of non-ferrous materials, only traditional mechanical clamps can be used.