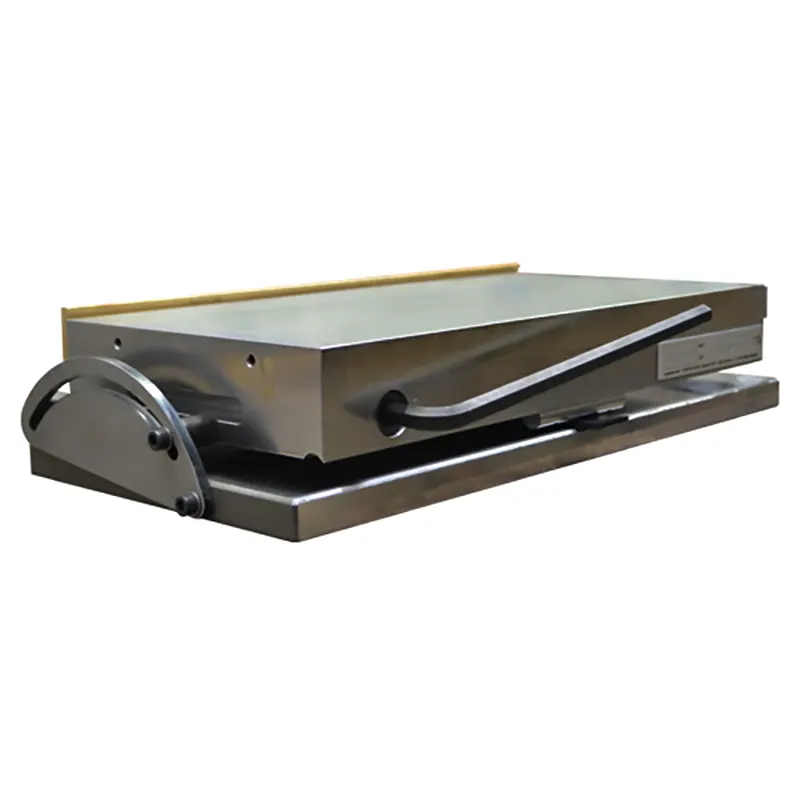

The Unidirectional Tilt Sine Table Permanent Magnetic Chuck Workbench is specifically designed to hold workpieces at precise angles for precision machining, grinding, and milling applications. This permanent magnetic chuck is equipped with a sine table, allowing for adjustable tilt angles to ensure optimal positioning of the workpiece during operations. Ideal for use in industries where high-precision, angular clamping is required, this chuck provides a secure hold on even delicate parts that need to be processed at specific angles.

Adjustable Tilt Sine Table:

This product features an adjustable sine table that allows the workpiece to be tilted at a precise angle. The tilt mechanism can be easily adjusted to the desired angle, making it versatile for a range of angular machining tasks. This feature is especially valuable for angled grinding, milling, and other operations that require workpieces to be held securely at non-perpendicular positions.

Customizable Magnetic Poles and Dimensions:

The magnetic chuck’s pole number, size, and pole bar dimensions are fully customizable, ensuring the chuck meets your specific needs. Whether you need a higher number of poles for more precise clamping or a specific pole spacing, we can tailor the product to match your requirements. The chuck’s design is robust, built to hold heavy and angular workpieces securely while maintaining a high level of performance.

High-Quality Materials and Durability:

Constructed from high-quality steel and reinforced with powerful permanent magnets, this chuck provides long-lasting, reliable performance. The magnets ensure consistent and strong holding force, keeping the workpiece firmly in place even during high-torque or high-speed operations. Additionally, the material choice guarantees durability and resistance to wear and tear, making the chuck suitable for continuous industrial use.

Key Features and Customization Options:

- Customizable Tilt Angle: Sine table allows for precise adjustment with a vertical angle setting range of 0 – 45° (or 0 – 30° horizontally);

- Excellent accuracy of +/- 5 arc seconds, even after extended use;

- Parallelism (Parallelism): +/- 5 microns per 100 mm;

- Pole Customization: Pole number, size and spacing can be customized to suit your application.

- Durability and High Holding Force: High-quality materials ensure the chuck maintains a strong clamping force for secure, precise positioning.

Important Parameters:

- Pole Number: Customizable to meet specific needs

- Pole Size: Customizable to optimize clamping force

- Tilt Angle: Adjustable from 0° to the maximum tilt angle (customizable)

- Chuck Dimensions: Customizable length, width, and height based on customer requirements

- Material: High-strength steel and permanent magnets

- Magnetic Force: Strong and reliable clamping force

- Temperature Range: Suitable for use in environments up to 80°C, with customizable temperature resistance

- Surface Treatment: Optional surface coatings for additional protection and wear resistance

- Holding force: 100 N/cm2

- Min. workpiece size: 4 x 4 x 1 mm

- Poles: Transverse

- Regrinding limit: 7 mm

- Pole pitch: T1.9 1.4+0.5 mm (steel/brass)

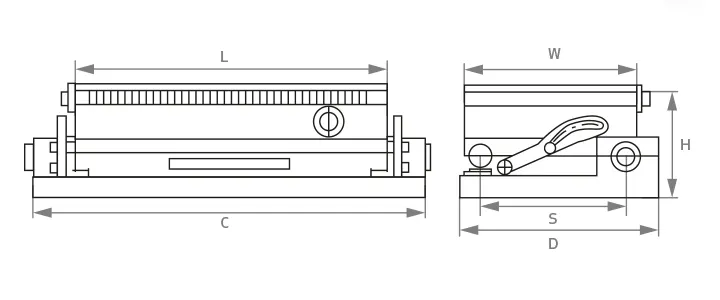

Common Specifications:

| Model | W (mm) | L (mm) | H (mm) | C x D (mm) | S (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| OSENC70140 | 70 | 140 | 67 | 130 x 140 | 55 | 7 |

| OSENC130255 | 130 | 255 | 76 | 295 x 145 | 115 | 20 |

| OSENC150250 | 150 | 250 | 79 | 290 x 165 | 135 | 20 |

| OSENC150300 | 150 | 300 | 79 | 340 x 165 | 135 | 27 |

| OSENC150350 | 150 | 350 | 87 | 390 x 165 | 135 | 34,5 |

| OSENC150450 | 150 | 450 | 87 | 490 x 165 | 135 | 44 |

| OSENC200400 | 200 | 400 | 88 | 440 x 215 | 185 | 52 |

| OSENC300600 | 300 | 600 | 95 | 660 x 320 | 285 | 121 |

Note: All specifications are customizable based on customer requirements.