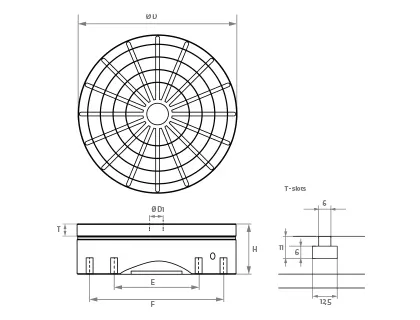

The Permanent Magnetic Chuck for Circular Grinding with Radial Poles is designed to provide robust, reliable clamping for circular grinding operations, ensuring that workpieces are held securely and precisely throughout the machining process. Its unique radial pole structure offers uniform magnetic force, ideal for high-precision grinding tasks where accuracy is critical. This chuck is widely used in surface grinding, cylindrical grinding, and precision machining applications.

Customizable Size and Design:

This permanent magnetic chuck can be customized to meet specific requirements. The diameter, height, and magnetic pole diameter are all adaptable to fit your unique machining needs. Whether you need a smaller, more compact chuck or a larger, heavy-duty solution, we can tailor the product to your exact specifications.

Magnetic Structure:

The radial pole configuration ensures that the magnetic field is evenly distributed across the chuck surface. This design minimizes the risk of uneven clamping force, which could affect the accuracy of the grinding process. By creating a uniform magnetic force, it guarantees a stable and secure hold for the workpiece, preventing any movement during operation.

Materials and Durability:

Made from high-quality steel and incorporating premium permanent magnets, the chuck is built to last, offering consistent performance over time. The aluminum base reduces the load on the machine tool spindle and increases the available weight capacity of the workpiece. The materials used ensure the chuck’s durability, making it suitable for use in high-demand environments and capable of withstanding frequent, heavy use.

Safe Main Structure:

Unique structure with self-locking switch mechanism, which can continuously adjust the holding force and facilitate the centering of the workpiece. Equipped with a self-locking mechanism to prevent the chuck from closing during processing. There are grooves and threaded holes on the bottom surface of the aluminum base for clamping to a suitable flange.

Key Features and Customization Options:

- Customizable Dimensions: We offer full flexibility in terms of chuck diameter, height, and magnetic pole diameter, allowing you to match the chuck to your machine’s requirements.

- Radial Pole Design: Ensures uniform magnetic distribution, providing secure clamping and preventing workpiece movement.

- High Clamping Force: Provides stable and precise clamping for circular grinding, even on delicate and small workpieces.

- Versatility: Suitable for a range of applications, including circular grinding, surface grinding, and cylindrical grinding, offering wide use in industries such as automotive, aerospace, and tool manufacturing.

Important Parameters:

- Pole Diameter: Customizable based on application needs

- Chuck Diameter: Customizable to meet workpiece sizes

- Height: Customizable to ensure compatibility with machine specifications

- Magnetic Force: High holding force for precision applications

- Working Temperature Range: Suitable for operations at temperatures up to 80°C, with optional higher-temperature options

- Surface Treatment: Can be customized with protective coatings to enhance durability and resistance to wear.

Parameters:

| Model | D (mm) | H (mm) | D1 (mm) | E (mm) | F (mm) | Hmotnost (kg) |

|---|---|---|---|---|---|---|

| D200 | 200 | 79 | 20 | 110 | 180 | 11,5 |

| D250 | 250 | 79 | 30 | 166 | 220 | 18 |

| D300 | 300 | 82 | 38 | 180 | 260 | 27 |

| D350 | 350 | 84 | 40 | 220 | 300 | 36 |

| D400 | 400 | 84 | 40 | 260 | 340 | 47 |

| D500 | 500 | 109 | 50 | 330 | 400 | 98 |

| D600 | 600 | 109 | 90 | 350 | 450 | 142 |

| Customized | ||||||