The Electro-Permanent Magnetic Milling and Drilling Magnetic Chucks are engineered to provide high-performance clamping for precision milling, drilling, and tapping applications. Utilizing an advanced electro-permanent magnet technology, these chucks combine the best features of permanent magnets and electromagnets, ensuring strong, stable clamping force for machining operations. They offer rapid activation and deactivation of the magnetic field without relying on continuous power, making them energy-efficient and safe to use.

Customization Options:

Our electro-permanent magnetic chucks are fully customizable to suit the unique requirements of your machining process. The pole dimensions, number of poles, and pole layout can be tailored to fit specific workpieces, ensuring maximum clamping strength and precision for your operations. Whether you need a larger chuck for heavy-duty tasks or a smaller one for fine machining, we can provide the right solution for your needs.

Design and Performance:

The electro-permanent magnet system allows for quick activation and deactivation of the magnetic field, which means less downtime and more productivity. The chuck provides a secure hold even on irregularly shaped or thin-walled workpieces, and the magnetic force can be controlled to suit different machining requirements. This makes it an ideal choice for industries that require high precision and flexibility in their workpiece clamping.

Materials and Durability:

Constructed from high-quality steel and premium permanent magnets, these magnetic chucks offer exceptional durability, stability, and resistance to wear. The materials ensure consistent performance, even in demanding environments. Top plate in steel/stainless steel combination guarantees high mechanical durability and thermal resistence.

Key Features and Customization Options:

- Electro-Permanent Magnet System: Combines permanent and electromagnet technology for optimal performance

- Customizable Pole Design: Adjustable pole dimensions, pole quantity, and layout for specific workpiece requirements

- Fast Activation/Deactivation: Efficient and quick switching for increased productivity

- Strong Holding Force: Provides secure and reliable clamping for milling, drilling, and tapping tasks

- Energy Efficient: No continuous power supply required during operation, saving energy and reducing risks

- Versatility: Suitable for a wide range of workpieces and applications, including irregular shapes and thin-walled components

Important Parameters:

- Pole Dimensions: 50 x 50 mm(Customizable based on application needs)

- Holding force: 170 N/cm2

- Min. workpiece size: 50 x 110 x 20 mm

- Poles: Square

- Regrinding limit: 6 mm

- Number of Poles: Customizable for different workpiece sizes and requirements

- Chuck Size: Customizable chuck diameter and height for various workpieces

- Magnetic Force: Adjustable clamping force, tailored to workpiece material and geometry

- Working Temperature Range: Suitable for temperatures up to 80°C, with higher-temperature options available

- Surface Treatment: Can be coated with protective finishes for enhanced durability

- Activation Mechanism: Rapid and secure magnetization and demagnetization cycle

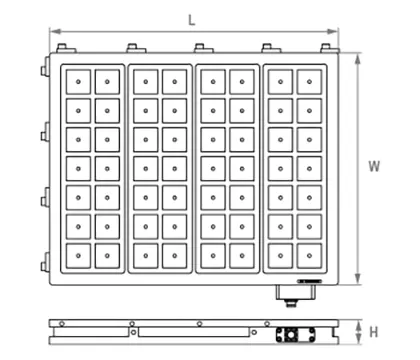

Parameters:

| Model | Number of poles | W (mm) | L (mm) | H (mm) | Weight (kg) |

|---|---|---|---|---|---|

| OSENC300490 | 24 | 300 | 490 | 51 | 49 |

| OSENC300600 | 32 | 300 | 600 | 51 | 61 |

| OSENC300800 | 40 | 300 | 800 | 51 | 82 |

| OSENC300900 | 48 | 300 | 900 | 51 | 92 |

| OSENC420490 | 36 | 420 | 490 | 51 | 70 |

| OSENC420600 | 48 | 420 | 600 | 51 | 86 |

| OSENC420800 | 60 | 420 | 800 | 51 | 114 |

| OSENC420900 | 72 | 420 | 900 | 51 | 128 |

| OSENC480600 | 56 | 480 | 600 | 51 | 97 |

| OSENC480800 | 70 | 480 | 800 | 51 | 130 |

| OSENC480900 | 84 | 480 | 900 | 51 | 146 |

| OSENC480990 | 84 | 480 | 990 | 51 | 161 |

| OSENC580800 | 80 | 580 | 800 | 51 | 157 |

| OSENC580900 | 96 | 580 | 900 | 51 | 177 |

| OSENC850990 | 96 | 580 | 990 | 51 | 194 |

Note: All models are customizable based on specific project requirements.