Working principle:

The Drum Magnetic Coupling is designed for efficient torque transmission without physical contact between the driving and driven components. The coupling operates using magnetic fields to transmit torque. As the drive wheel rotates, its rare earth magnets interact with the permanent magnets in the internal rotor, creating a powerful magnetic connection. This mechanism allows for smooth and uninterrupted torque transmission, eliminating wear and maintenance issues associated with traditional couplings.

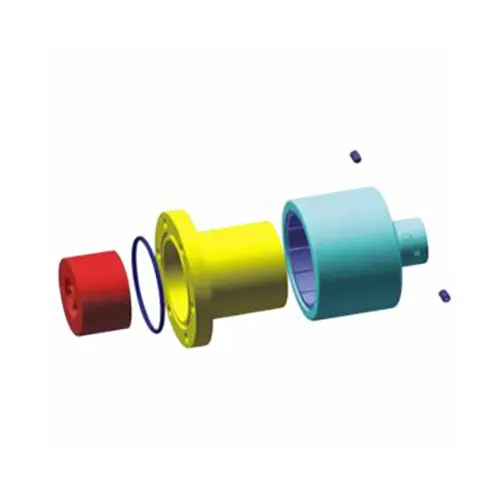

Structure

- Rotor: The rotor consists of a cold-rolled steel shaft that is powder-coated for enhanced corrosion resistance. It fits precisely into the isolating cover, ensuring proper alignment for optimal performance.

- Isolating Cover: This molded polypropylene disc acts as a barrier between the internal rotor and the rotor itself. It prevents air from entering the system while allowing the magnetic field to pass through seamlessly.

- Internal Rotor: Located on the inner surface of the drive wheel, the internal rotor is equipped with permanent magnets. These magnets play a vital role in establishing the magnetic connection necessary for torque transmission.

- Drive Wheel (Stator): The drive wheel contains a series of rare earth magnets strategically positioned to interact with the internal rotor’s magnets. This design not only facilitates torque transmission but also enables self-alignment during operation.

Applications

The Drum Magnetic Coupling is particularly suitable for environments where hygiene and contamination prevention are paramount. Its robust design and non-contact operation make it ideal for:

- Food Processing: Ensuring clean operations without contamination risks.

- Beverage Industry: Facilitating the movement of liquids and ensuring product integrity.

- Pharmaceuticals: Maintaining sterile conditions while driving machinery.

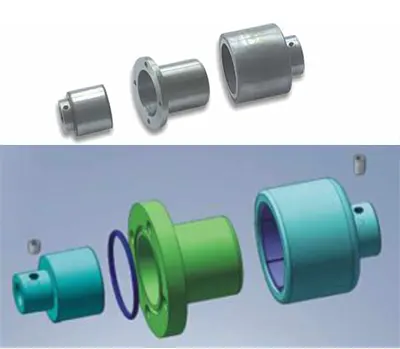

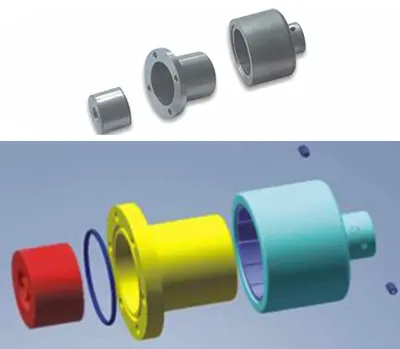

3 common drum magnetic couplings:

| Unthreaded Hole Drum Magnetic Coupling | Axel Hole Drum Magnetic Coupling | Flange Drum Magnetic Coupling |

|---|---|---|

|

|

|

Drum magnetic couplings provide a variety of designs according to actual applications to meet the needs of different industries. By using magnetic technology, the drum magnetic couplings we produce ensure reliable torque transmission, thereby improving performance. Our team can also provide tailor-made solutions to meet your specific needs.