Working principle:

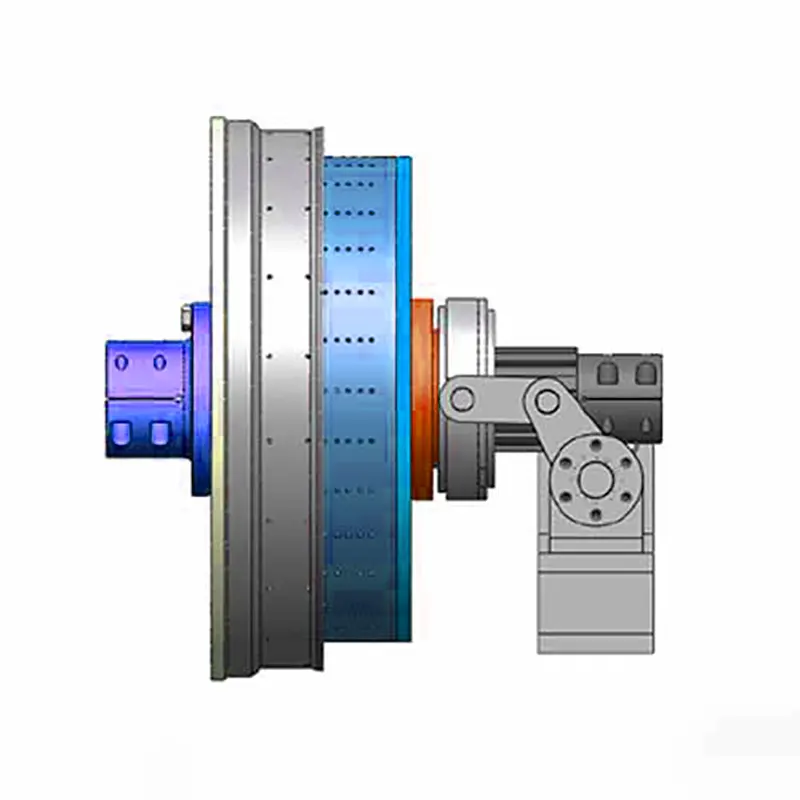

The adjustable speed magnetic shaft coupling consists of three main components: the permanent magnet rotor, the conductor rotor, and the adjustment mechanism. Both rotors are exposed to air, allowing for effective cooling.

The adjustment mechanism enables the alteration of the axial coupling area between the permanent magnet rotor and the conductor rotor. When the main motor rotates the conductor rotor, it interacts with the permanent magnet at the driven end. This relative motion generates an eddy current in the conductor rotor, producing an induced magnetic field that interacts with the permanent magnetic field of the driven rotor. This process allows for contactless torque transmission between the driving and driven ends.

The coupling area plays a critical role in this system: a larger coupling area results in a stronger magnetic field due to increased interaction with the magnetic lines of force. Consequently, this enhances the torque transmitted to the load, increases the load speed, and improves the overall output power. Conversely, a smaller coupling area weakens the magnetic field, reducing torque, load speed, and output power.

In practical applications, the coupling area is adjusted according to the load size, allowing for effective speed regulation and energy savings. This adaptability makes the adjustable speed magnetic shaft coupling a versatile solution for various industrial applications.

Industry:

- Water and wastewater treatment

- Power generation

- Cement

- Maritime

- Pulp and paper manufacturing

- Chemical and food processing

- Oil and gas processing

- Mining

- Irrigation

- HVAC

Application:

Pumps/Fans/Blowers/Centrifuges/Bulk handling equipment;