Use:

Widely used in steel, mining, coal, chemical, paper and textile, shipbuilding, cement and other industries (such as conveyors, bucket wheel machines, excavators, elevators, ball mills, crushers, rod presses, coal mills, stackers, mixers, boiler slag crushers and other power equipment).

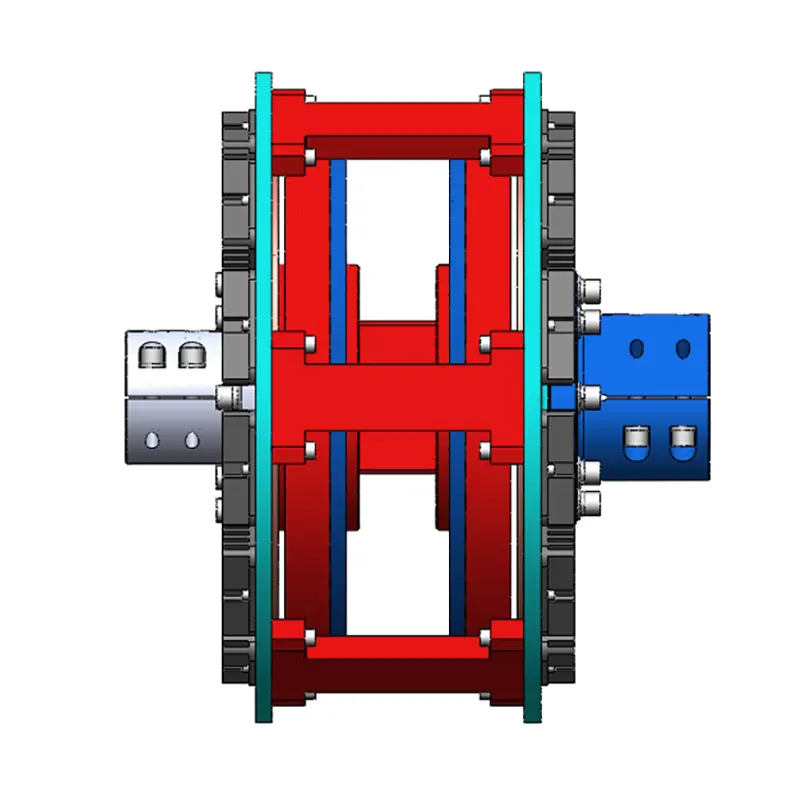

Working principle:

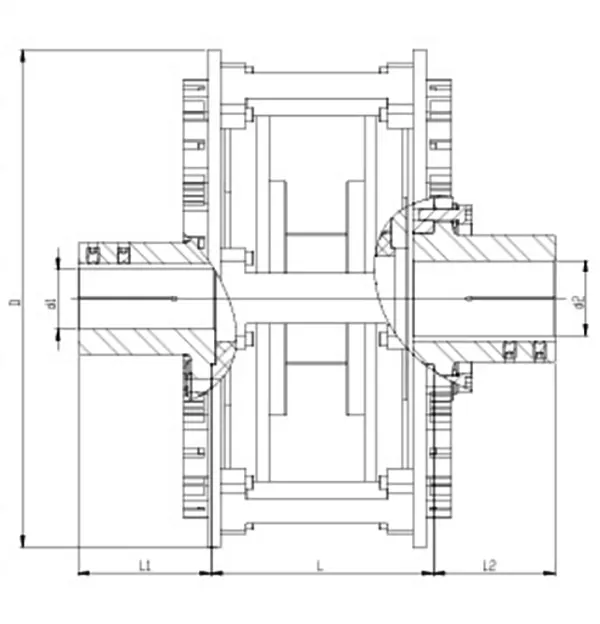

The torque-limiting permanent magnetic coupling is generally composed of a magnet rotor and a conductor rotor. There is a variable air gap between the magnetic rotor and the conductor rotor. When the main motor drives the conductor rotor to rotate, it makes a circular motion relative to the magnet installed on the driven end to cut the magnetic lines of force. The active end conductor rotor generates an eddy current induction magnetic field, which interacts with the driven end magnetic field to achieve contactless torque transmission between the active end and the driven end.

When the working machine is overloaded or stuck, the air gap between the torque-limiting permanent magnetic coupling rotor and the conductor rotor increases rapidly until the air gap is reached, and the speed of the magnetic rotor at the working machine end decreases or reaches zero, thereby achieving overload protection for the motor. When the overload or stuck condition is relieved, the position of the magnetic rotor and the conductor rotor is restored to the original minimum air gap through the recovery mechanism, and the machine returns to normal working state.

| Specification | D(mm) | L(mm) | Power(Kw) | Speed(r/min) |

|---|---|---|---|---|

| OX-270 | 340 | 189 | 11-15 | 1500 |

| OX-300 | 370 | 189 | 18.5-22 | 1500 |

| OX-300 | 400 | 189 | 30/18.5/15 | 1500/1000/750 |

| OX-350 | 420 | 189 | 37/22/18.5 | 1500/1000/750 |

| OX-370 | 440 | 189 | 45-55/30-37/22-30 | 1500/1000/750 |

| OX-420 | 490 | 189 | 75-90/45-55/37-45 | 1500/1000/750 |

| OX-450 | 530 | 189 | 110-132/75-90/55 | 1500/1000/750 |

| OX-480 | 560 | 189 | 160-185/110/75-90 | 1500/1000/750 |

| OX-520 | 600 | 189 | 200-220/132/110 | 1500/1000/750 |

| OX-560 | 640 | 189 | 250-28/160-185/132 | 1500/1000/750 |

| OX-580 | 660 | 204 | 315/200/160 | 1500/1000/750 |

| OX-620 | 700 | 204 | 355-400/220-250/185-200 | 1500/1000/750 |

| OX-650 | 730 | 220 | 450/300/220 | 1500/1000/750 |

| OX-700 | 810 | 257 | 56/355/280 | 1500/1000/750 |

| OX-720 | 810 | 257 | 630/400/315 | 1500/1000/750 |

| OX-750 | 860 | 257 | 710/450/355 | 1500/1000/750 |