Custom Magnetic Coupling Solutions Manufacturer

A magnetic coupling is a component that provides non-contact torque transfer, allowing torque to be transmitted through the air or through obstacles. Utilizes magnetic fields rather than physical mechanical connections to transfer torque from one shaft to another. Osencmag provides precision-engineered, customizable magnetic couplings to your exact needs. Customized excellence, guaranteed results.

Comprehensive Custom Magnetic Coupling Services

Specific Torque Requirements

Osencmag supports specific torque needs with custom magnetic couplings, ensuring precise torque transmission for both low and high torque applications.

Sizes

We customize magnetic couplings in a variety of sizes, carefully designed and tested to meet your application requirements.

Magnet Material

Choose from high-performance Neodymium (NdFeB) or Samarium Cobalt (SmCo) magnets, designed for demanding conditions.

Temperature Rating

Our Neodymium magnets support temperatures up to 230°C (AH series), while SmCo withstands up to 350°C for extreme environments.

Housing Materials

Select from cold-rolled steel, alloy steel, stainless steel, magnetic stainless steel, beryllium copper, and aluminum alloy for optimal durability.

Barrier Materials

We offer stainless steel, alloy metals, plastics, and ceramic barriers to ensure maximum protection and efficiency.

Conductive Materials

Our eddy current magnetic couplings feature custom conductive materials, including aluminum and copper. The eddy current magnetic field interacts with the input magnetic field to create torque transfer.

Surface Treatments

Available surface treatments include zinc plating, nickel plating and custom coatings to enhance durability, corrosion resistance and service life of magnetic couplings.

Magnetic Couplings We Developed

-

Magnetic coupling

Adjustable Speed Magnetic Shaft Coupling

-

Magnetic coupling

OFS Series High Torque Magnetic Coupling

-

Magnetic coupling

Classic Drum Magnetic Coupling

-

Magnetic coupling

OFX series composite torque limited permanent magnetic coupling

-

Magnetic coupling

OS Series Standard Three-disk Permanent Magnet Coupling

-

Magnetic coupling

BX Series Torque limited mining magnetic coupling

-

Magnetic coupling

OTB Series For Permanent Magnet Synchronous Coupling

-

Magnetic coupling

OX Series standard torque limiting permanent magnetic coupling

Trusted Magnetic Coupler Supplier with Custom Solutions

At Osencmag, we specialize in comprehensive, reliable custom manufacturing services for magnetic couplers, ensuring a high-performance solution for every application. Our team of experts provides tailor-made coupler designs, including custom shaft and housing construction, to meet your specific requirements. Prioritizing quality while maintaining confidentiality and guaranteeing that your product designs are protected throughout the development process. Partner with us to gain precision engineering, unparalleled quality, and flexible customization options to increase the efficiency and lifespan of your products.

What is magnetic coupling?

Also known as magnetic coupler or magnetic shaft coupling, magnetic couplings utilize two rotors made of rare earth permanent magnets to transfer torque between two shafts without direct physical connection. In addition to the air gap, torque can also be transferred through a non-magnetic flat barrier, which is achieved through the interaction of magnetic fields generated by permanent magnets within the coupling. By eliminating contact between the driving hub and the driven hub, magnetic couplings prevent wear, reduce maintenance and ensure no leakage, making them ideal for sensitive environments such as chemical processing, pharmaceutical production and fluid handling systems.

The basic principle of magnetic coupling is simple but effective. It involves aligning two magnetically interacting rotors – one connected to the driving shaft and the other to the driven shaft. When the driving rotor rotates, it generates magnetic force, transmitting torque to the driven rotor, allowing the system to operate seamlessly without direct contact. In certain applications, it can also turn a dynamic seal into a static seal, achieving zero leakage. This ensures high efficiency and reliability, especially in applications where traditional couplers may fail due to environmental factors such as high temperature or corrosive fluids.

| Features of Magnetic Couplings | |

|---|---|

| Feature | Description |

| Non-Contact Torque Transmission | Magnetic couplings transmit torque without physical contact, reducing wear and eliminating friction. |

| Leak-Free Operation | Ideal for fluid or gas systems, magnetic couplings ensure zero leakage, preventing contamination and maintaining safety. |

| Low Maintenance | With no moving parts in contact, magnetic couplings require minimal maintenance compared to traditional couplings. |

| Vibration Isolation | They absorb vibrations, leading to smoother operations and less stress on connected machinery. |

| Corrosion Resistance | Using materials like stainless steel and ceramics, magnetic couplings resist corrosion in harsh environments. |

| High Durability | Designed to withstand extreme conditions, including high temperatures and corrosive chemicals. |

| No Mechanical Wear | The absence of direct contact between components eliminates mechanical wear, extending the product’s service life. |

| Precision Alignment | Magnetic couplings offer high tolerance to misalignment, reducing the need for precise mechanical alignment. |

| Customizable Torque Capacity | Can be tailored to specific torque requirements, making them suitable for a range of low to high-torque applications. |

| Silent Operation | The non-contact design ensures quieter operation compared to traditional mechanical couplings. |

| Synchronous Design, No Slip at High Speed | Magnetic couplings are designed to synchronize perfectly at high speeds, eliminating slip and improving performance. |

| High Energy Efficiency | Due to the non-contact nature and reduced friction, magnetic couplings operate with improved energy efficiency. |

| High Temperature Resistance | With rare-earth magnets like Samarium Cobalt, magnetic couplings can withstand extreme temperatures up to 230-350°C. |

What is a magnetic coupling used for?

Magnetic couplings are used in a wide range of industries where leak-free, contamination-free torque transmission is required. Magnetic couplings excel in applications involving fluids or gases, such as pumps, agitators, and compressors in industries such as chemical manufacturing, food processing, and water treatment. The ability to transmit power while maintaining a sealed environment makes them an indispensable machine component for handling corrosive substances, hazardous chemicals, and sterile environments where contamination control is critical.

In addition, magnetic couplings are valued for their vibration isolation properties. By eliminating direct mechanical contact, they help reduce vibration and misalignment issues, extending the life of the machine and ensuring smoother operation. This makes them ideal for precision equipment, from medical devices to high-end laboratory instruments, where accuracy and reliability are critical.

What types of magnetic coupler structure prototypes are there?

Magnetic couplings consist of several key components, including magnets, rotors, and housings. The most critical rotating shaft is composed of rare earth permanent magnets (NdFeB or SatinCo), magnetic shielding materials, etc. These components are arranged in a unique way to transfer torque without direct contact using the magnetic field generated by permanent magnets. The different structures of the coupling not only affect its performance, but also determine its applicability in different application areas. Common prototype structures of magnetic couplings are: disc (or planar) magnetic couplings, drum coaxial magnetic couplings, and linear magnetic couplings.

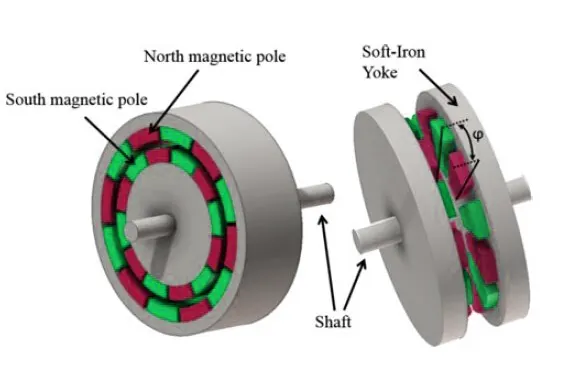

Disc Magnetic Coupling

Disc magnetic couplings, also known as plane couplings, consist of two parallel flat rotors. Each disc is embedded with a ring-shaped permanent magnet. They are installed on two discs of the same diameter by crossing the NS poles. When in use, the two discs are installed on the driving shaft and the driven shaft respectively. Although there is a certain air gap between the two, the N pole of the magnet on the driving shaft attracts the S pole of the opposite driven shaft magnet and repels the N poles on both sides of the S pole magnet of the driven shaft. This ensures efficient and synchronous transmission of torque between the two components within a certain torque range. The overall structure is compact and is an ideal solution for applications with limited space. The simple structure also reduces maintenance requirements.

Working principle Torque

In the disc magnetic coupling, torque is transmitted through the magnetic force generated by the opposite poles of the magnets on the two discs. When the driving rotor rotates, the magnetic interaction forces the driven rotor to follow the movement. Due to the principle of plane attraction, the smaller the air gap, the greater the torque, and vice versa. In addition, since the transmitted torque is proportional to the area of the disk, the torque capacity depends on the magnet attraction, size and arrangement, as well as the air gap between the disks. The specific needs need to be combined with the actual operating environment to avoid overloading the system.

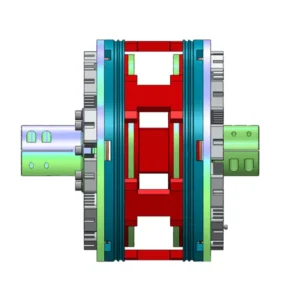

Drum coaxial magnetic coupling

The drum coaxial magnetic coupling is the most widely used synchronous transmission device in the “pump” field. It mainly consists of three parts: outer rotor, inner rotor, and sealed shielding sleeve, which are connected to form a complete bearing system. It adopts a cylindrical design, with two concentric rotors, one inside and the other outside, nested. The outer contour of the inner rotor and the inner contour of the outer rotor are both composed of a series of rare earth magnets and metal profile packaging. The sealed shielding sleeve physically separates and seals the driven rotor from the driving rotor. This design is particularly suitable for applications with high torque or involving highly toxic or corrosive chemicals, such as industrial pumps and agitators. For actual application scenarios, we provide fully customizable manufacturing for the outer rotor and inner rotor of the coaxial permanent magnetic coupling.

Working principle Torque

The drum magnetic coupling transmits torque radially through the interaction of magnets on the inner and outer rotors. This radial magnetic force has higher torque capacity and better alignment than a flat design over a disc coupling, making it ideal for heavier loads. The torque in a drum coupling is more evenly distributed in the magnetic field, resulting in less wear and increased durability. The torque capacity can be further customized to meet the specific needs of high-performance industrial equipment by adjusting the strength of the magnets or the size of the rotor.

Linear Magnetic Couplings

Unlike the two types of rotary magnetic couplings above, linear permanent magnetic couplings are used to transmit linear motion. Magnets are arranged along the fixed and moving parts, and the magnets are arranged in a straight line. This structure enables the coupling to smoothly transmit linear motion without mechanical contact, making it suitable for applications such as automatic production lines and precision machinery.

Working Principle Torque

In a linear magnetic coupling, the coupling does not transmit rotational torque, but instead generates a magnetic force that moves the parts in a linear direction. The force applied depends on the size and arrangement of the magnets, as well as the distance between the moving and fixed parts. This type of coupling provides precise, non-contact motion, reduces wear and ensures long service life. Although linear force is not usually described as “torque”, it plays an equal role in applications where precise control of motion is required.

By comparing the different types of magnetic couplings, buyers can make an informed decision on which prototype is right for your operational needs. Osencmag’s ability to provide custom solutions for each type ensures our customers receive a coupling tailored to their specific torque, alignment and structural requirements, building trust and fostering long-term partnerships.

| Disc Magnetic Coupling, Drum Coaxial Magnetic Coupling and Linear Magnetic Coupling Comparison | |||

| Attribute | Disc Magnetic Coupling | Drum Coaxial Magnetic Coupling | Linear Magnetic Coupling |

|---|---|---|---|

| Coupling Type | Flat, planar design with parallel rotors | Cylindrical design with concentric rotors | Linear design for transferring straight-line motion |

| Axial Force | Moderate | High | Low to moderate |

| Slip Torque Adjustment | Limited adjustability due to fixed magnet positions | High adjustability by changing rotor size | Not applicable (focus is on linear force, not torque) |

| Containment Barrier | Available in thin-walled metal, ceramic, or plastic | Available in thicker metal or composite barriers | Available in metal, ceramic, plastic, or composite materials |

| Angular Misalignment Capacity | Low tolerance for angular misalignment | High tolerance for angular misalignment | Not applicable (focus is on alignment along a straight path) |

| Parallel Misalignment Capacity | Moderate capacity for parallel misalignment | High capacity for parallel misalignment | Not applicable (linear couplings don’t rely on alignment the same way) |

| Maximum Torque | Moderate torque transmission | High torque transmission for heavy loads | N/A for torque; applies linear force |

| Max Operating Temperature | Up to 230°C with NdFeB, up to 350°C with SmCo | Up to 230°C with NdFeB, up to 350°C with SmCo | Up to 230°C with NdFeB, up to 350°C with SmCo |

| Applications | Precision machinery, small pumps, space-limited systems | Industrial pumps, mixers, high-torque systems | Linear actuators, conveyor systems, precision automation |

What types of magnetic couplings are there?

Magnetic couplings are roughly divided into three types according to the way they transmit torque based on the coupling principle between two shafts or components: synchronous couplings, eddy current couplings, and hysteresis couplings. Each coupling works differently and has unique advantages depending on the application.

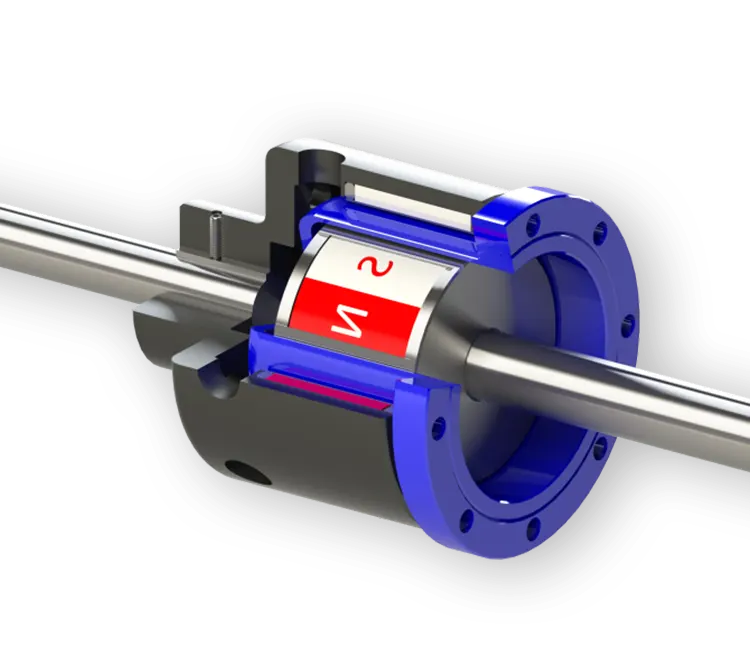

Synchronous magnetic couplings

Synchronous magnetic couplings rely on the attraction and repulsion between the permanent magnets on the drive and driven components to achieve torque transmission, and the input and output components are equipped with magnetic poles in relative positions. When the drive components move, they pull the magnets of the driven components. The transmission of torque depends entirely on the synchronous rotation of the magnetic field, so the input and output ends have the same speed.

Therefore, synchronous magnetic couplings have the characteristics of precise synchronization, no slip, and high efficiency. Suitable for applications that require precise speed and position matching. Able to be used in sealed environments to prevent liquid or gas leakage.

Application scenarios: Widely used in pumps, sealed fluid transmission systems, chemical equipment agitators and compressors that require precise, non-slip torque transmission.

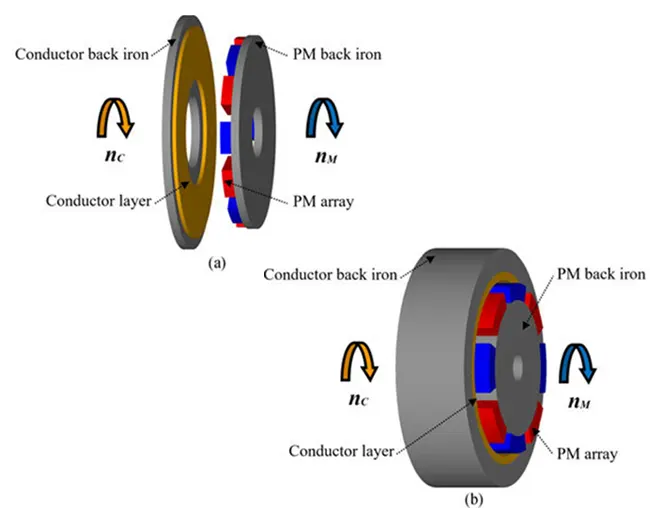

Eddy current magnetic coupling

Eddy current couplings use eddy currents generated by magnetic fields in conductive materials (such as aluminum or copper) to transmit torque. When a conductor (usually aluminum or copper) passes through the magnetic field generated by the magnet on the drive component, a current is induced in the conductor. These currents generate a changing magnetic field in the rotating magnet at the input end, and induce eddy currents in the conductive material at the output end. The magnetic field generated by the eddy current interacts with the magnetic field at the input end to form torque transmission.

Since the speed of the input and output ends of the eddy current coupling can be different, it has slip. It can provide flexible torque transmission and avoid instantaneous shock. It is suitable for occasions with large speed changes and can protect itself when the load is too large.

Application scenarios: Commonly used in applications that require buffering torque and require adjustable speed and slip, such as motor starting, fans, mixers and conveyors, or for variable speed equipment.

Hysteresis magnetic coupling

Hysteresis magnetic couplings use magnetic materials with hysteresis loops, that is, when the hysteresis material is exposed to a magnetic field, it will delay magnetization and generate torque. The permanent magnet at the input end interacts with the hysteresis material at the output end through the magnetic field to produce a stable and controllable torque. This produces a stable and constant torque. The hysteresis coupling can provide stable slip torque transmission within a certain range, and the torque will not change dramatically with the change of speed, and has a constant torque output characteristic.

Application scenario: Hysteresis couplings are particularly suitable for applications that maintain constant torque and precision control, such as clutches, tension control systems, winding equipment, test equipment, and metering pumps.

We know:

- Synchronous couplings—the input and output are precisely synchronized, without slip, suitable for applications that require precise torque transmission.

- Eddy current couplings—rely on eddy currents to transmit torque, with slip, suitable for flexible torque transmission and variable speed occasions.

- Hysteresis couplings—use hysteresis effects to provide constant torque, with stable slip characteristics, suitable for constant load applications.

By understanding the different types of magnetic couplings and how they work, companies can better determine the ideal solution to meet their operational needs. Osencmag specializes in custom magnetic couplings that can be tailored to precise specifications such as torque, alignment, materials, and environmental conditions. Our expertise ensures you receive precise, reliable couplings that help you achieve lasting results in your most challenging applications.

What are the types of materials for each component of the magnetic coupler?

The performance of magnetic couplings relies on a range of materials. The material selection for each component (magnets, conductive materials, structural parts and barriers) affects not only the function of the coupler, but also its compatibility with a specific environment. Each material is selected for its specific properties to optimize performance. Below is an overview of the materials we commonly use for each component in the manufacturing process of magnetic couplings, which can be customized according to different application needs.

Magnet Materials

The magnet is the heart of the magnetic coupling, and choosing the right type is critical to performance.

- Neodymium (NdFeB): Known for its high magnetic strength, it is ideal for applications that need to produce high torque at lower temperatures (usually recommended below 150°C, AH series can reach up to 230°C). Anti-corrosion surface treatment is required.

- Samarium Cobalt (SmCo): Resistant to high temperatures (up to 350°C) and corrosion, suitable for harsh environments. Anti-corrosion treatment is optional.

- Hysterlloy: A balance between magnetic strength and temperature resistance (up to 350°C), commonly used in sensitive applications where hysteresis couplings need precise control.

Barrier (Isolation) Materials

In many magnetic couplings, a physical barrier is placed between the magnets to create a sealed environment to prevent leakage in sensitive applications such as pumps or compressors. These barriers must be non-magnetic to avoid interfering with the magnetic field.

- Non-magnetic Stainless Steel: Suitable for moderate pressure and speed applications, moderate cost. Low strength, also low conductivity.

- Nickel-Based Alloys: Suitable for high pressure and high speed applications, extremely strong. Provides a strong barrier in extreme environments, has strong corrosion and heat resistance. Higher cost, low conductivity.

- Plastics (Nylon, Teflon, Polyacetal, Ultra Polymers): Lightweight and corrosion resistant. Suitable for low pressure, chemical, low temperature and precise force applications. Moderate cost, low strength, non-conductive.

- Ceramic: Suitable for high speed and precision force applications. Has excellent heat resistance, often used in specialized applications requiring high durability and non-magnetic properties. Non-conductive, moderate to high cost, low to moderate strength.

Structural Body Materials

The structural body or housing of a magnetic coupling plays an important role in maintaining magnet alignment and ensuring durability under mechanical stress. Common options include:

- Cold rolled steel (1018, 1045, etc.): Affordable and strong, requires corrosion protection. Suitable for general purpose couplings with low to medium strength.

- Alloy steel (4140, 4340, etc.): High wear resistance and strength, moderate cost. High strength is often used in heavy-duty applications.

- Magnetic stainless steel (416, 430, 17-4PH, etc.): Combines the durability and magnetic properties of stainless steel, moderate to high cost. Suitable for specialized magnetic applications, strength depends on ambient temperature.

- Non-magnetic stainless steel (316, 304, etc.): Moderate cost. Excellent corrosion resistance, ideal for environments requiring non-magnetic properties. Strength depends on ambient temperature.

- Nickel-based alloys (Inconel, Hastelloy, Monel, etc.): High cost, but also very strong. Excellent heat and corrosion resistance, used in extreme environments such as aerospace and chemical processing.

- Beryllium Copper: High strength and non-sparking properties, often used in explosive or flammable environments. High cost and strength.

Aluminum: Lightweight and corrosion resistant, often used in applications requiring high speed, low torque couplings. Low cost, low strength.

Conductive Materials

Conductive materials are used in eddy current magnetic couplings, where they interact with a magnetic field to transmit torque.

- Aluminum: Lightweight and cost-effective, often used in eddy current couplings where weight reduction is a priority.

- Copper: Highly conductive, used in high torque couplings where maximum efficiency and torque transfer are critical.

By selecting the right materials for each component, you can ensure your magnetic coupling meets specific performance and environmental requirements. Whether you require high torque, corrosion resistance, or specific environmental compatibility, Osencmag can provide a custom solution to your exact specifications. Our custom manufacturing process ensures that you receive a magnetic coupling made with the highest quality materials to last even in the most demanding applications.

Past Case Studies

Why choose us as your magnetic coupling partner?

At Osencmag, we pride ourselves on our comprehensive capabilities in designing, manufacturing, and delivering high-quality Permanent magnetic coupling. Here’s a detailed look at our expertise:

Proven Custom Manufacturing Expertise

With over 20 years of experience in custom magnetic products, we understand the complex needs of magnetic coupling solutions. The accumulated engineering knowledge enables us to provide custom requirements that meet your exact specifications and functions.

Comprehensive Testing and Quality Assurance

Our magnetic couplings are rigorously tested at every stage of production to ensure compliance with the highest industry standards. We ensure that each product is tested for durability, performance, and compliance with your technical requirements.

Complex Structure Customization Capabilities

We specialize in the design and development of complex coupling structures, including unique housings, coupling structure configurations, and material combinations. We provide flexible solutions for a variety of complex or unique designs to meet the specific needs of your application.

Efficient Supply Chain and Fast Delivery

Utilizing comprehensive and reliable supply chain resources, we have developed an efficient production process. Quickly deliver custom magnetic couplings without compromising quality. Even with complex designs, our unique SOP ensures on-time delivery.

Confidentiality and Intellectual Property Protection

Protecting our customers' designs and intellectual property is one of our guidelines. Strict confidentiality agreements are followed to ensure that your proprietary information is fully protected throughout the development and manufacturing process.

Advanced Materials and High Temperature Resistance

We use high-performance neodymium magnets and samarium cobalt magnets to ensure optimal performance even in extreme environments. Our magnetic couplings can withstand extreme temperatures up to 230°C and 350°C, respectively, ensuring reliable operation in the harshest conditions.

Strong OEM and R&D Capabilities

We provide complete OEM services and work with you to develop new magnetic coupling solutions from concept to completion. Our R&D team has the ability to innovate and improve product designs, including prototype testing and iterative improvements to help you turn your ideas into reality.

Safe Packaging and Global Shipping

We provide secure, customized packaging solutions to protect your magnetic couplings during transportation. We have in-depth cooperation with well-known global transportation companies to ensure that the products are delivered to you safely and timely.

Other Magnetic Assemblies

Other Precision Magnetic Assemblies Products We Support

Magnetic Rotors

Magnetic Rotors

Designed for high efficiency and durability, magnetic rotors enhance the power and life of motors and generators.

FAQs about magnetic coupling

What industries can benefit from magnetic coupling solutions?

Magnetic couplings offer versatility and reliability, making them ideal for a wide range of industries.

- Chemical processing plants benefit from their ability to create leak-free seals, especially in environments dealing with corrosive or hazardous materials.

- Pharmaceutical and food industries use magnetic couplings to ensure contamination-free processes.

- In marine and offshore applications, they help drive pumps and fans in environments where corrosion resistance is essential.

- HVAC systems, automotive, and aerospace sectors also utilize these couplings for their ability to transmit torque without physical contact, reducing wear and maintenance needs.

Whatever your industry, Osencmag provides custom magnetic coupling solutions tailored to specific operational requirements.

How does Osencmag ensure the quality of magnetic couplings?

At Osencmag, quality is our top priority. We adhere to strict manufacturing standards and employ advanced quality control measures at every stage of production. Our couplings undergo rigorous testing for strength, durability, and performance to ensure they meet both industry standards and specific client requirements. We use high-grade materials like neodymium and samarium cobalt magnets and precision engineering to guarantee optimal performance, even in harsh conditions. Each batch is tested for torque transmission, alignment precision, and corrosion resistance. Additionally, we provide custom reports and certifications to meet your quality assurance needs, ensuring full transparency and trust.

What is the lead time for custom magnetic couplings?

Our lead time for custom magnetic couplings depends on the complexity and quantity of your order. Typically, we require 4 to 6 weeks for production, including time for design consultation, prototyping, and testing. If you’re placing a large bulk order or require special materials or coatings, the timeline might extend slightly, but we always aim for efficient production without compromising quality. For urgent needs, we offer expedited services to meet tight deadlines. Rest assured, our team works closely with you throughout the process to provide regular updates and ensure timely delivery.

What is the minimum order quantity for bulk orders of magnetic couplings?

At Osencmag, we support flexible order quantities to accommodate different client needs. For custom magnetic couplings, our minimum order quantity (MOQ) typically starts at 100 units, though this can vary based on the specific design and materials required. We understand that smaller orders may be necessary for prototyping or limited runs, so we offer scalable production solutions to match your project’s scope. For large bulk orders, we provide competitive pricing and discounts based on quantity. Contact our team for tailored solutions that fit your budget and production needs.