Wholesale Custom High-Quality Laminated Magnet Manufacturer

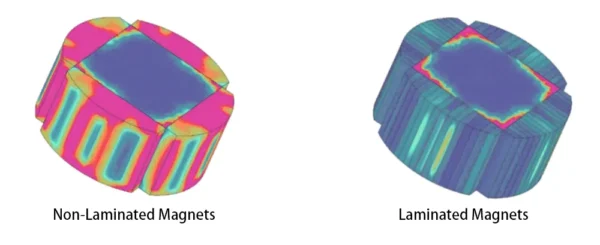

Laminated magnets are made up of multiple individual magnets that are bonded and insulated from each other. They improve performance in high frequency applications by preventing magnet overheating and reducing eddy current losses. Osencmag’s cutting and laminating technology and expertise in producing custom laminated magnets ensures you get a high quality product.

-

Laminated Magnets

Black epoxy NdFeB laminated magnet low eddy current loss

-

Laminated Magnets

High-speed motor arc-shaped NdFeB laminated magnets

-

Laminated Magnets

Transversely magnetized tile-shaped samarium cobalt laminated magnets

-

Laminated Magnets

Eddy current segmented square permanent magnet laminated magnets

-

Laminated Magnets

Precision stator & rotor arch bridge-shaped laminated permanent magnet

-

Laminated Magnets

High power segmented arc laminated magnet block

Laminated Magnet Manufacturing Customized on Demand

Magnet Type Customization

We offer multiple specifications of Neodymium (NdFeB) and Samarium Cobalt (SmCo) magnets that can be customized to your specific performance requirements and environmental conditions.

High Temperature Resistance

Customize the operating temperature range to your application to ensure your laminated magnets maintain optimal performance under specific conditions.

Custom layers

Customize the number of layers of bonded laminated magnets to your specific needs to optimize magnetic performance and reduce eddy current losses.

Thickness Customization

Customize the thickness of each laminate layer to achieve the desired optimal balance between magnetic strength and eddy current reduction.

Magnetization direction

We offer customizable magnetization directions to suit your application requirements, whether axial, radial or multi-pole magnetization etc.

Shape and Size

Define the exact size and shape to fit your design, from simple geometries to complex configurations.

Other Magnetic Accessories

Other permanent magnet product accessories & parts we support

Warning: Attempt to read property "post_type" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 433

Warning: Attempt to read property "post_status" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 439

Warning: Attempt to read property "post_status" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 442

Warning: Attempt to read property "ID" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 443

Notice: Function map_meta_cap was called incorrectly. When checking for the edit_post capability, you must always check it against a specific post. Please see Debugging in WordPress for more information. (This message was added in version 6.1.0.) in /home/u362093030/domains/osencmag.com/public_html/wp-includes/functions.php on line 6078

Warning: Attempt to read property "ID" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 445

Warning: Attempt to read property "post_type" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 433

Warning: Attempt to read property "post_status" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 439

Warning: Attempt to read property "post_status" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 442

Warning: Attempt to read property "ID" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 443

Notice: Function map_meta_cap was called incorrectly. When checking for the edit_post capability, you must always check it against a specific post. Please see Debugging in WordPress for more information. (This message was added in version 6.1.0.) in /home/u362093030/domains/osencmag.com/public_html/wp-includes/functions.php on line 6078

Warning: Attempt to read property "ID" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 445

Warning: Attempt to read property "post_type" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 433

Warning: Attempt to read property "post_status" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 439

Warning: Attempt to read property "post_status" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 442

Warning: Attempt to read property "ID" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 443

Notice: Function map_meta_cap was called incorrectly. When checking for the edit_post capability, you must always check it against a specific post. Please see Debugging in WordPress for more information. (This message was added in version 6.1.0.) in /home/u362093030/domains/osencmag.com/public_html/wp-includes/functions.php on line 6078

Warning: Attempt to read property "ID" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 445

Warning: Attempt to read property "post_type" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 433

Warning: Attempt to read property "post_status" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 439

Warning: Attempt to read property "post_status" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 442

Warning: Attempt to read property "ID" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 443

Notice: Function map_meta_cap was called incorrectly. When checking for the edit_post capability, you must always check it against a specific post. Please see Debugging in WordPress for more information. (This message was added in version 6.1.0.) in /home/u362093030/domains/osencmag.com/public_html/wp-includes/functions.php on line 6078

Warning: Attempt to read property "ID" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 445

Warning: Attempt to read property "post_type" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 433

Warning: Attempt to read property "post_status" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 439

Warning: Attempt to read property "post_status" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 442

Warning: Attempt to read property "ID" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 443

Notice: Function map_meta_cap was called incorrectly. When checking for the edit_post capability, you must always check it against a specific post. Please see Debugging in WordPress for more information. (This message was added in version 6.1.0.) in /home/u362093030/domains/osencmag.com/public_html/wp-includes/functions.php on line 6078

Warning: Attempt to read property "ID" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 445

Warning: Attempt to read property "post_type" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 433

Warning: Attempt to read property "post_status" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 439

Warning: Attempt to read property "post_status" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 442

Warning: Attempt to read property "ID" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 443

Notice: Function map_meta_cap was called incorrectly. When checking for the edit_post capability, you must always check it against a specific post. Please see Debugging in WordPress for more information. (This message was added in version 6.1.0.) in /home/u362093030/domains/osencmag.com/public_html/wp-includes/functions.php on line 6078

Warning: Attempt to read property "ID" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 445

Warning: Attempt to read property "post_type" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 433

Warning: Attempt to read property "post_status" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 439

Warning: Attempt to read property "post_status" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 442

Warning: Attempt to read property "ID" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 443

Notice: Function map_meta_cap was called incorrectly. When checking for the edit_post capability, you must always check it against a specific post. Please see Debugging in WordPress for more information. (This message was added in version 6.1.0.) in /home/u362093030/domains/osencmag.com/public_html/wp-includes/functions.php on line 6078

Warning: Attempt to read property "ID" on null in /home/u362093030/domains/osencmag.com/public_html/wp-content/plugins/elementor-pro/core/utils.php on line 445

Let Osencmag be your reliable laminated magnet supplier

Osencmag understands that precision, reliability and expertise are essential in the field of laminated magnets. Our expertise in producing custom laminated magnets and advanced manufacturing equipment in our factory ensure that you get reliable laminated magnets. Whether it is for high-performance products such as motors, generators or transformers, we handle complex custom requirements with innovative solutions. Rigorous testing protocols and strict quality assurance measures ensure that every laminated magnet we produce performs at its best.

Technical Background on Laminated Magnet.

As the demand for more efficient and powerful motors for modern high-performance motor and electromagnetic applications grows, so does the need to reduce energy losses, especially those caused by eddy currents. Motor eddy currents generate heat and energy losses, which can severely affect the efficiency of a motor or generator, and can even cause magnetic materials to overheat and demagnetize prematurely. Laminated magnets are particularly important in this context, addressing these challenges by reducing the formation of eddy currents. Laminated magnet structures interrupt the eddy current paths, significantly reducing their size and associated energy losses. This makes laminated magnets particularly valuable in high-performance applications where efficiency and reliability are critical.

What Are Laminated Magnets?

Laminated magnets are specially designed magnetic components that are cut and stacked with multiple thin layers or magnetic materials (the entire stack has the same polarity), also known as segmented magnets. These magnet layers are bonded together with insulating materials to form independent magnets that are insulated from each other, thereby reducing eddy current losses.

The main materials are made of neodymium iron boron (NdFeB) and samarium cobalt (SmCo), both of which are known for their strong magnetic properties and excellent performance in a variety of environments. The insulating material between the magnet layers is usually a non-conductive coating such as epoxy or polyimide, which effectively prevents the formation of eddy currents.

The use of laminated magnets is an important advancement in motor technology, helping the industry to continue to push the limits of electric motors and generators. They can improve performance while alleviating some common magnetic issues.

In summary, laminated magnets provide an advanced solution to the challenges posed by eddy currents and high-temperature demagnetization. By properly using laminated magnets in motor product development, higher efficiency, better thermal management and longer-lasting magnetic performance can be achieved. These are key factors in today’s competitive and demanding technical environment.

What Are the Benefits of Using Laminated Magnets?

Laminated magnets are manufactured using magnet splitting technology, making them ideal for high resistivity magnets (uniform magnetic field across the surface). They offer several key benefits.

- The most important benefit is reduced eddy current losses. By breaking up the conductive path inside the magnet, the laminated structure limits the formation of eddy currents, which reduces heat generation and reduces energy waste.

- Higher thermal stability. In applications where temperature fluctuations are common, the insulating layers within the magnet help balance power and heat, reducing the negative effects that can lead to overheating. This makes laminated magnets ideal for high-frequency applications such as electric motors.

- Laminated magnets can also be customized to meet specific application needs. Whether you require a specific layer thickness, magnetic orientation, or custom shape and size, laminated magnets have the flexibility to be designed to provide the exact performance characteristics required for a specific application.

By choosing laminated magnets from a trusted supplier like Osencmag, you gain the technical advantages of this advanced magnetic solution, ensuring that each laminated magnet meets the specific needs of your application, from precise layer thickness to optimal magnetic orientation.

Where Are Laminated Magnets Used?

Laminated magnets are widely used in applications where minimizing energy losses and maximizing efficiency are critical due to their unique advantages and structure.

- Electric Motors

Brushless DC Motors (BLDC): Laminated magnets are used to enhance the efficiency and performance of BLDC motors by reducing eddy current losses, which is crucial for maintaining high rotational speeds.

Permanent Magnet Synchronous Motors (PMSM): In PMSMs, laminated magnets help improve the power output and thermal management, especially in electric vehicles and industrial machinery. - Transformers

High-Frequency Transformers: Laminated magnets are used in high-frequency transformers to minimize core losses and enhance energy transfer efficiency, particularly in power supplies and converters.

Pulse Transformers: These magnets are integral to pulse transformers, ensuring precise energy transfer in applications such as telecommunications and digital circuits. - Renewable Energy Generators

Wind Turbine Generators: Laminated magnets are employed in the rotors of wind turbine generators to reduce energy losses and increase the overall efficiency of power generation.

Hydroelectric Generators: In hydroelectric generators, laminated magnets contribute to reliable and efficient energy conversion, ensuring stable power output. - Magnetic Sensors

Hall Effect Sensors: Laminated magnets are used in Hall effect sensors to provide consistent magnetic fields, which are essential for accurate position and speed sensing in automotive and industrial applications.

Magnetoresistive Sensors: These sensors benefit from laminated magnets’ ability to reduce interference from eddy currents, improving sensitivity and precision in applications such as motion detection and navigation systems. - Inductors

High-Frequency Inductors: Laminated magnets in inductors help manage the magnetic flux and reduce losses, which is vital in applications like RF circuits and power electronics.

Chokes: In choke coils, laminated magnets improve the performance of noise filtering and power conditioning in electrical circuits. - Magnetic Bearings

Active Magnetic Bearings: Laminated magnets are used in active magnetic bearings to provide stable, contact-free support for rotating shafts, which is essential in high-speed applications such as turbines and compressors.

Passive Magnetic Bearings: In passive magnetic bearings, these magnets reduce friction and wear, contributing to longer service life and improved reliability.

By integrating laminated magnets into these applications, industries can achieve greater efficiency, reliability, and performance. Osencmag’s expertise in custom magnet production ensures that each laminated magnet is tailored to meet the specific demands of your application, from motor efficiency to sensor accuracy.

What materials and coatings are available for laminated magnets?

When it comes to laminated magnets, the choice of materials and coatings plays a critical role in determining the magnet’s performance, durability, and suitability for specific applications. Osencmag’s manufacturing facilities use high-quality materials and coatings that can be customized to the precise needs of a customer’s project, ensuring optimal results and long-term reliability.

Materials:

The core materials used in laminated magnets are primarily Neodymium (NdFeB) and Samarium Cobalt (SmCo). Neodymium magnets are well-known for their exceptional magnetic strength, making them the go-to choice for applications requiring powerful magnetic fields. However, they are more susceptible to corrosion and may have lower thermal stability compared to Samarium Cobalt. This is where Samarium Cobalt shines, offering excellent resistance to corrosion and high temperatures, making it ideal for environments where the magnets are exposed to extreme conditions.

The choice between Neodymium and Samarium Cobalt depends on the specific requirements of your application. For instance, if your project demands maximum magnetic strength and operates in a controlled environment, Neodymium might be the best fit. On the other hand, if your application involves high temperatures or corrosive environments, Samarium Cobalt offers superior performance and longevity.Our professional engineers will give you the best advice based on the information obtained from communicating with you during the early stages of your order.

Coatings:

To enhance the durability and performance of laminated magnets, various coatings can be applied. These coatings provide additional protection against environmental factors such as moisture, chemicals, and physical wear, which can otherwise degrade the magnet over time.

- Epoxy Coating: Epoxy is a popular choice for its excellent adhesion and resistance to moisture, chemicals, and mechanical stress.

- Nickel Coating: Nickel is popular for its strong corrosion resistance and smooth surface, and is particularly useful in applications where the magnets are exposed to wet or corrosive environments.

- Polyimide Coating: Polyimide is known for its high thermal stability and insulation properties, making it an excellent choice for extreme temperature applications. It can maintain its performance under harsh thermal conditions.

- Custom Coatings: Depending on your specific needs, we can also provide custom coatings for your application. These coatings may include Teflon for non-stick properties, gold for increased conductivity, rubber for increased impact resistance and grip, parylene, titanium or phosphating, among other diverse options.

Selecting the right materials and coatings for laminated magnets is critical to ensuring their performance and longevity. High-quality materials combined with a rigorous and precise bonding and cutting process produce highly stressed laminated magnets. With Osencmag’s extensive experience in custom magnet production, we can select the right materials and coatings for our customers’ laminated magnet orders. You can be confident that each magnet is crafted to the highest standards of quality and precision.

What quality assurance and testing do our laminated magnets undergo?

To ensure the reliability and performance of our laminated magnets, we adhere to stringent quality assurance protocols and rigorous testing procedures at every stage of production. This commitment to quality not only guarantees that our products meet the highest industry standards but also instills confidence in our clients, knowing that they are receiving magnets that will perform reliably in their applications.

- Raw material inspection:

One of the critical aspects of our quality assurance process is material verification. Before production begins, we conduct thorough inspections of all raw materials, including the magnetic alloys and insulating layers. By verifying the material composition and properties, we ensure that the magnets will have the desired magnetic performance and durability. - Dimensional inspection:

During the manufacturing process, our laminated magnets undergo precise dimensional inspections to ensure that they meet the exact specifications required by our clients. We utilize advanced measurement tools and techniques to verify the thickness of each lamination layer, the overall dimensions of the magnet, and the alignment of the magnetic orientation. - Magnetic performance functional test:

In addition to dimensional checks, we perform a series of functional tests to assess the magnetic performance of our laminated magnets. These tests include measuring the magnetic field strength, coercivity, and remanence to confirm that the magnets deliver the required magnetic properties. For applications that involve high-frequency environments, we also conduct eddy current loss testing to ensure that our laminated magnets effectively minimize energy losses, thereby enhancing overall efficiency. - Thermal testing:

Thermal testing is another crucial component of our quality assurance process. Laminated magnets are often used in environments where temperature stability is critical. We subject our magnets to temperature cycling tests to assess their performance under varying thermal conditions. - Persistence simulation test:

Finally, we perform durability testing to evaluate the mechanical robustness of our laminated magnets. This includes tests for impact resistance, corrosion resistance, and overall structural integrity. By simulating the conditions that magnets will face in real applications, we can ensure they will perform for the purposes our customers intend.

At Osencmag, our commitment to quality is unwavering. With over 20 years of experience in the industry, we understand the importance of delivering products that our clients can rely on. Our comprehensive quality assurance and testing procedures are designed to provide peace of mind, knowing that our laminated magnets will perform with excellence and reliability in even the most demanding applications. If you’re seeking a trusted partner for your laminated magnet needs, our expertise and dedication to quality make us the ideal choice.

FAQs about Laminated Magnets

What are the lead times and delivery options for laminated magnets?

Lead times for laminated magnets depend on the complexity of your custom requirements and the volume of your order. Typically, production lead times range from 4 to 6 weeks. However, we understand that in the fast-paced world of manufacturing, deadlines can be tight. That’s why we offer expedited production services to meet urgent demands without compromising on quality. Once your order is ready, we provide flexible delivery options, including air and sea freight, to ensure your magnets reach you as quickly and efficiently as possible. With Osencmag, you can trust that your order will be delivered on time, every time, backed by our commitment to reliable service and customer satisfaction.

Are laminated magnets environmentally friendly and compliant?

Yes, laminated magnets are designed with both performance and environmental responsibility in mind. The materials used in our laminated magnets, such as Neodymium (NdFeB) and Samarium Cobalt (SmCo), are sourced from suppliers who adhere to strict environmental and safety standards. Additionally, the insulation coatings used in the laminations are chosen not only for their efficiency in reducing eddy currents but also for their low environmental impact.

What Certifications Do Laminated Magnets Have?

Laminated magnets supplied by Osencmag are certified to comply with international standards such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and ISO (ensuring product reliability and tolerance consistency). These certifications ensure that our products are safe, environmentally friendly and free of hazardous substances. In addition, we can provide specific certifications upon request based on the regulatory requirements of your industry. This ensures that your purchase is not only technically sound but also in compliance with international standards.

Can laminated magnets be customized to specific thicknesses or layer counts?

Yes, laminated magnets can be fully customized according to the application’s requirements. The thickness of the lamination layers and the number of layers can be adjusted based on the desired balance between minimizing eddy currents and maintaining magnetic strength.

How to ensure the quality of laminated magnets before bulk ordering?

We understand the importance of quality assurance, especially for bulk orders. To help you evaluate our laminated magnets, we provide sample production before full production. Ensure that the product quality and performance meet customer expectations. We also provide detailed inspection reports for each order, so you can be confident in the quality of our products before making bulk purchases.